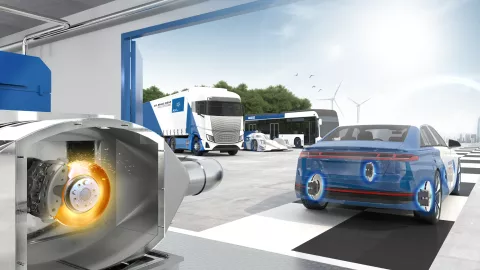

Our innovative test automation software, iGEM 2, is designed to meet all your testing needs. Whether it's emission testing on engines, powertrains, small off-road engines (SORE), brakes, or vehicle testbeds, iGEM 2 has you covered. It also supports the full range of electrification testing, including hybrid, battery electric, and hydrogen systems. With iGEM 2, you get high-quality data for certification testing and adaptable solutions for research and development.

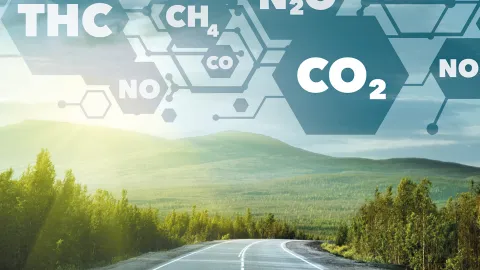

The automotive industry is facing its biggest challenge in the history since its origin. Increasingly complex and tough global legislations paired with the rise of new electric propulsion systems are the new imperative. Global markets are demanding greater numbers and more sophisticated powertrain variants and propulsion systems. As a result, testing efforts have grown dramatically. Rising test volumes, driven by more and longer test cycles, demand that your testing infrastructure is optimized for maximum efficiency and productivity. Tackling this challenge requires the latest in cutting-edge test automation tools. The latest generation of AVL iGEM 2 was designed to address those challenges.

Regulation Compliance

Use our standardized application packages to comply with the latest regulations. The modular design allows to easily extend your testing scope.

Managing Complexity

Our software solution helps to manage the increasing number and complexity of global legislations for the user.

Various Applications

iGEM 2 is available for diverse testbed configurations, such as Engine, Vehicle, Powertrain, SORE and Brake Wear testing.

Traceability

We provide full transparency of each measurement value and calculation during the entire workflow to ensure full chain of custody.

We have based iGEM 2 on the platform of AVL PUMA 2™ and AVL CONCERTO 5™. These provide test execution and data processing functionalities, along with a wide range of features for exceptional testing capabilities.

This comprehensive solution ensures that you are provided with everything you need to optimize your testing processes. Such as:

- Traceability of all data and results

- Test execution status control

- Graphical workflow support

- Extensibility, thanks to the iGEM 2 API

- Minimal maintenance effort

At the heart of iGEM 2 are a series of benefits and features that make it a must for your testing toolchain and infrastructure.

EASE OF USE

The test application is independent of the device type and testbed configuration. This enables users to execute the same test cycle across diverse testbed configurations.

PERFORMANCE

Get instant results during and after the test. No load times between tests and optimized device operation parallelization boost the productivity of your testbed.

HIGHLY CUSTOMIZABLE

Our modular application library is open for easy customization. Dedicated editors allow an easy and secure customization without the need of programming skills.

Fulfilling All Needs for Electrification and Hydrogen Testing

Repeating test cycles with various end of test criteria are managed in a most efficient way to assure highest throughput and efficiency. Testbed users are guided by iGEM 2 throughout the entire testing process to assure valid data and error-free operation.

For the testing of H2-ICE and Fuel Cell Vehicles, H2 fuel consumption measurement is supported with detailed reports and data available in any test phase.

Brake Emission Testing

With our latest configuration - iGEM 2 for Brake Emission Testing - we provide a regulation conform test automation solution for brake testing. The solution to automate the regulatory test procedures and calculations is based on and realized with our well-known and established iGEM 2 test automation software. With the rising importance of brake emission testing, our software is one step ahead of future legislative trends.

Performance Extension

The iGEM 2 Performance extension allows to define test sequences and execute them (semi-)automatically - most efficient through the parallel execution of multiple tasks. The framework includes valuable features such as rapid UUT cooldown, test block creation, automated xCU workpage changes, and interfaces with INCA or ATI.

By conducting more tests in a shorter timeframe, the overall calibration time is reduced, leading to increased efficiency. Additionally, the need for fewer prototypes results in significant cost savings.

Transform your e-mobility analysis with AVL CONCERTO 6™️, featuring fast data access, AI-driven technologies, advanced visualizations and calculations, and auto-generated reports for superior performance and precise insights.

AVL PUMA 2™ is the global industry standard for testbed automation. It is suitable for electrified testbed types as well as for conventional test environments.

AVL Process Control Modules constitute a powerful selection of software modules to assist you in all necessary steps involved in the testing process and result evaluation.

The new benchmark for full-flow diluted emission testing is designed to take up much less space than conventional system cabinets and is built to use less energy.

The AVL AMA SL is a exhaust measurement system that is revolutionizing emission testing. It is ideally suited to both research and development applications and certification for all types of engines and fuels.

With software maintenance, AVL ensures the value and stability of AVL software for the customer throughout the entire product life cycle

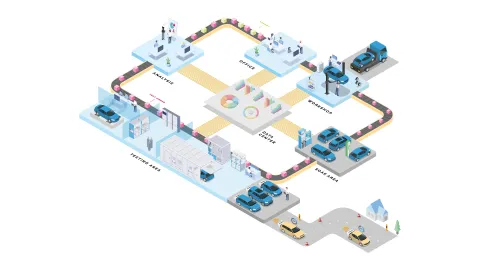

Increase the efficiency and effectiveness of your test lab.

Achieve process safety and higher efficiency with our modular and scalable Lab Management for Vehicle solution.

WEBINAR - Brake wear is one of the most significant non-exhaust traffic-related sources of particulate matter and, as a result, will be included in future emission regulations. Due to the broad size range of brake wear particles new instruments are required.

In this webinar, Kurt Engeljehringer shares details of AVL’s free Emission and Energy Testing Handbook, which aims to help engineers understand and navigate this complex topic.

AVL has been awarded the contract to provide nearly all the software and hardware for light and heavy duty vehicle, engine, and powertrain testing at the new California Air Resources Board’s (CARB) lab in Riverside, California.