AVLは試験装置だけではなく、パワートレインや推進システムなどのハイテクエンジニアリングも提供しています。AVLは、コンポーネントから車両全体まで、将来の自動車開発要件に合わせて常に調整し、革新的でユーザー指向のソリューションを探求しています。その責任を果たすために、機器の試験だけではなく、計画初期段階から、ニーズを評価し、特定の高性能ソリューションの策定するまで、パートナーに適した幅広い範囲で製品を提供しています。

NVH(ノイズ、バイブレーション、ハーシュネス)テストベンチソリューションは、騒音源の音響減衰と試験システムの構造部分からの音響反射を最適化しています。これにより、対象となるもの、つまり被試験ユニットが、各音響測定の中心になることを保証します。さらに、AVLは厳格な音響基準への理解や取り組みを通じ、各試験システムに対して一般に認められるNVH目標を達成することを目指しています。すべてのコンポーネントを調整し、合否分析を通じてシステムの妥当性確認を実施し、そのパフォーマンスを証明します。

e-モーター向けNVHソリューション

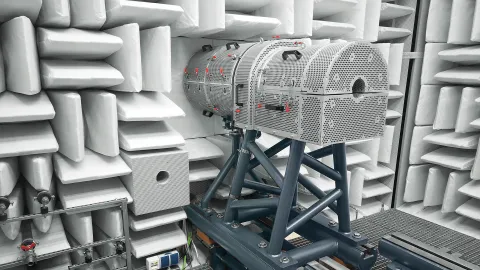

e-モーターの妥当性を確認するNVH試験システムでは、すべての被試験ユニット(UUT)のバリエーションに対応しています。AVLは、NVHの開発課題を迅速で効率的かつ持続的に解決可能な開発環境の構築を目指しています。NVH試験システムは、主要な機能の優先度に応じてさまざまなソリューションを提供します。つまり、あらゆるUUTの3つの主要な領域、プレミアムセットアップ、精密セットアップ、効率セットアップにまとめることができます。→詳細はこちら

e-アクスル向けNVHソリューション

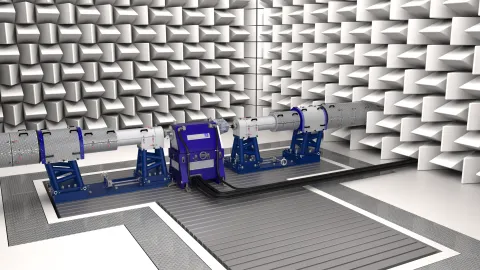

NVHパワートレインテストベンチの経験を活かして、e-アクスルに高品質の音響試験環境を提供できます。すべてのコンポーネントおよび音響筐体は、シミュレーションにより最適化された設計を通じて、音響反射を最小限に抑えることで優れたNVH性能を確保するように設計されています。テストベンチコンポーネントは操作が非常に簡単になるように重視されています。可動式装填ユニットにより、さまざまな試験片サイズに適応できます。→→ 詳細はこちら

NVHは、車両やパワートレインの騒音を改善するだけではなく、ブランドとしてのサウンドを確立し、最新車両に乗る人々を感動させることも目指しています。AVLのNVH試験システムとソリューションと組み合わせて、車両やコンポーネント向け音響開発用の高品質な開発プラットフォームを提供し、未来のモビリティの素晴らしさを推進しています。

– Department Manager, AVL List GmbH Joachim Schmidt

NVH testing in e-mobility, which stands for Noise, Vibration, and Harshness testing, is essential for optimizing the comfort and sound quality of electric vehicles. AVL offers advanced testbeds, simulation technologies and engineering services to measure, analyze and optimize NVH characteristics. Their comprehensive testing solutions cover everything from individual components to complete vehicle systems, addressing parameters such as high-frequency noise, wind and road noise and structural integrity. AVL helps manufacturers meet stringent acoustic standards, improve vehicle comfort, and create a distinctive sound profile for electric vehicles.

It makes sense to do NVH testing in all development stages, starting from conceptualization over to simulation models, and finally to the complete product. In early development phases, NVH topics can be addressed easier in accordance to the overall project goals. Late involvement of NVH development typically leads to high costs in redesign and restrictions in solutions findings before start of production. AVL provides NVH Test Systems and simulation tools for single components, such as e-motors and inverters, over to component assemblies, such as e-axles, and finally for the fully assembled vehicle.

NVH testing is crucial for electric vehicles because it helps improve driver and passenger comfort by minimizing unwanted noise and vibrations, which are more noticeable in quieter electric drivetrains.

Common challenges include managing high-frequency noise from electric motors, reducing wind and road noise, and ensuring the structural integrity of lightweight vehicle components.

AVL provides a range of NVH testing solutions, including test systems for e-motors, e-axles, and complete vehicles, designed to meet stringent acoustic standards and optimize vehicle sound quality. Furthermore, AVL supports in any development and production stage of a vehicle and its components with tailored testing solutions, from highly flexible R&D test systems to automated end of line monitoring systems.

AVL NVH test systems are designed to achieve ultra-low background noise levels for highest signal and noise ratios.

- Seamlessly integrated test bed automation, data acquisition and simulation tools that help to reduce development time significantly.

- Simulation of real dynamic operating conditions as they appear on the road.

- Supporting a big variety of industries ranging from high speed (e.g. 36,000 rpm) to high torque (eg. 50 kNm) application.

- Flexible and variable design for quick adjusting to different powertrain systems

- Always up to date with the latest NVH requirements and norms

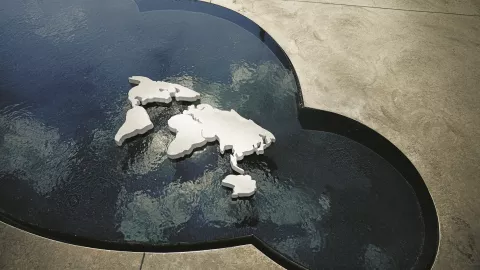

- With an installed base of currently over 200 NVH test beds worldwide, AVL underlines our strong commitment towards NVH development and testing.

- AVLs customers benefit of the strength and expertise of a big global player and, at the same time, having the comfort of a reliable local team. Efficient project teams cooperate in a mix of local and global engineers, each with high expertise in their own field: Project managers, layout designers, NVH engineers and many more.

- More than 25 years of experience in NVH development

- More than 120 engineers are working with NVH topics daily, in vehicle development, simulation and test system design.

- AVL continuously keeps up with the latest NVH development trends. AVLs high-class development platform is industry proven and highly adaptive for specifically tailored NVH testing solutions.

- AVL provides NVH Test Systems and simulation tools for single components, such as e-motors and inverters, over to component assemblies, such as e-axles, and finally for the fully assembled vehicle.

- AVL provides testing solutions for any stage in the vehicle development process, starting from conceptualization over to simulation models, and finally to the complete product.

AVL’s NVH testing solutions help manufacturers meet stringent acoustic standards, ensuring compliance with regulatory requirements and enhancing overall vehicle comfort and sound quality.

AVL offers a comprehensive software portfolio for simulation (e.g. AVL EXCITE™), automation (PUMA™) and data acquisition and analysis (AVL CAMEO™ , AVL Concerto™, X-ion™ for NVH). Furthermore, AVLs complete testing solutions serve to acoustically validate and optimize components and whole vehicles over their total development and production cycle.

Simulation supports NVH testing by allowing engineers to predict and analyze noise, vibration, and harshness characteristics early in the design process, reducing the need for multiple physical prototypes. It enables virtual prototyping and integration of test and simulation data, enhancing the accuracy of NVH predictions. This approach is cost-effective and helps ensure regulatory compliance while improving overall design. Here, AVL EXCITE™ supports the modeling of components, subsystems and complete drive units with varying levels of detail. One of EXCITE's core competences is the calculation of structure-borne and airborne noise of powertrain units. Evaluation tools such as Operational Deflection Shape (ODS), Numerical Transfer Path Analysis (NTPA) and Modal Contribution Factors (MCF) give you answers to the causes and sources of excitation and vibration.

AVL provides testing equipment which is integrated to semi or full anechoic chambers according to ISO3745. The low background noise level allows highly accurate sound power measurements and NVH development. The testing equipment is fully compatible with the required quantity and positions of the microphones according to ISO3744 and ISO3745.

AVL is known for its consistent integration of normative specifications, established industry solutions and special customer requests into the overall concept of the test system.