バッテリーパック、モジュールおよびセル、燃料電池、e-モーターおよびe-アクスルに関する各ソリューションは、いかなる環境においても安全かつ確実に動作しなければなりません。この環境には、極端な温度や湿度が含まれます。こうした極端な温度や湿度は、試験コースや路上走行時での実際の試験シナリオでは再現できません。そのためAVLは、モジュール式のAVL Climate Chamberを開発しました。

コンポーネントは幅広い環境条件に耐えられるものでなければなりません。北極の冬のような極寒の環境でも、塗装室のような高温の環境でも動作できなければなりません。また、湿度は、パフォーマンス、材料応力、および耐用年数に大きな影響を及ぼす可能性があり、さらに、熱衝撃を発生させることで、耐用年数試験を早めることができます。この気候室では、最新の基準に適合するために必要な全ての試験を行うことが可能です。

テストベンチのさまざまなパーツを統合

AVLは、試験ソリューション一式を提供しています。

試験中のバッテリー破壊

AVLの安全システムは、お客様のニーズに合わせて開発されています。

試験エリア要件に合わせてカスタマイズが可能

標準製品のカスタマイズが可能です。

バッテリー試験は新しく成長するアプリケーション

AVLは、試験システムの経験が豊富で、信頼できるパートナーです。

この気候室は、IEC 60068-3-5規格に準拠した加熱と冷却の温度勾配を持ち、指定された温度範囲内で動作します。平均温度は、熱負荷のない供給空気で測定され、熱補償値は使用される電源の種類に基づいて調整されます。

ウォークインチャンバーでは、さまざまな種類の試験機器のニーズに対応できるよう寸法が最適化されています。同様に、セルテストチャンバーのサイズも、セルテストベンチ用に最適化されたソリューションを採用するために慎重に調整されています。

この気候室の断熱材は、ポリウレタンやミネラルウールなど、要求される安全レベルに応じて選択できます。エネルギー消費を削減するために、上水道を利用することで、冷却装置に必要な冷却電力を減らし、全体的なエネルギー消費量を減らすことができます。

特にバッテリープロトタイプを試験する場合、被試験デバイスに重大な熱問題が発生する可能性があります。潜在的なダメージを軽減するために、この気候室には周囲の建物を保護する浸水オプションを装備することができます。さらに、AVLはテストベンチのハザードレベル4または6を達成するために設計された包括的な安全システムを提供しています。

屋外設置の場合, サーマルテストベンチ一式をコンテナ内に設置することができ、熱試験のニーズに対応した多用途で効率的なソリューションを提供します。

技術データ |

|

|

温度範囲 |

–40 °C up to +90 °C |

| 標準温度変化率 |

2 K/min or 4.5 K/min |

| 電池パックのテストセル容量 |

16 m³ or 22 m³ |

| バッテリーセル・テスト・チャンバー・サイズ |

720 – 1.500 liter |

| 断熱材 |

ポリウレタンまたはミネラルウール |

| 冷却水の流れ |

12 °C up to 30 °C |

| 安全バージョン | ハザードレベル6まで |

| 設置 |

バッテリーパックと燃料電池システムのための気候室 |

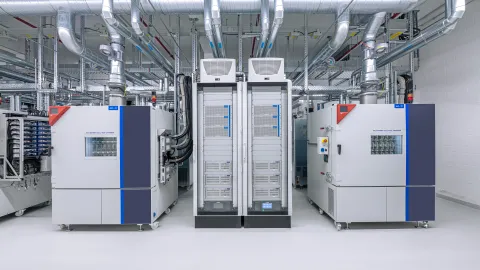

Climatic Chamber

for Battery Cell Testing

Our battery cell testing climatic chambers are designed to hold up to 12 or 16 cells, making them ideal for rigorous testing. They offer a wide temperature range from -40°C to 90°C and use environmentally friendly CO2 as a refrigerant. The chambers are equipped with a water-cooled system to maintain optimal conditions and ensure even airflow, minimizing temperature fluctuations. With the ability to quickly heat or cool, these chambers are perfect for testing in various scenarios. They are energy efficient, supporting heavy racks with loads up to 500 kg, with an option for 750 kg. Integrated in the AVL Battery Cell TS™, they deliver accurate and reliable test results.

Climatic Chambers

for Battery Pack and Fuel Cell Testing

Our climatic chambers for battery pack and fuel cell testing provide precise control over internal operating temperatures, with a temperature range of -40°C to +90°C. These chambers are available in volumes of 16 m³ or 22 m³, with customizable sizes also possible. They ensure reliable testing results and adhere to IEC 60068-3-5 standards. The temperature gradient for heating and cooling is carefully managed, with average values measured in the supply air, even without a thermal load. For battery prototypes, our chambers can be flooded as a safety measure to prevent critical thermal issues, ensuring protection for both the batteries and the surrounding building.

Safety Systems

Our climate chamber can be designed for EUCAR Hazard Level 4 or Hazard Level 6. They also offer superior safety with flooding options for maximum protection of the testbed and facility. Moreover, we provide customized battery testing safety systems with our automotive testing experience.

Individual Solutions

Our climatic chambers offer a seamless integration into existing testbeds with their unique and application-based design, facilitated by pre-defined interfaces. With their high functional flexibility, these chambers allow for easy and fast upgrades. Each climatic chamber can be tailored to meet the specific requirements of every customer.

Individual Design and

Premium Material

The climate chamber is constructed of high-alloy, corrosion-resistant steel. They are suitable for testing batteries, fuel cells or electric drives. Porthole packages, mounting options and electrical feedthroughs are specifically designed for each test area.

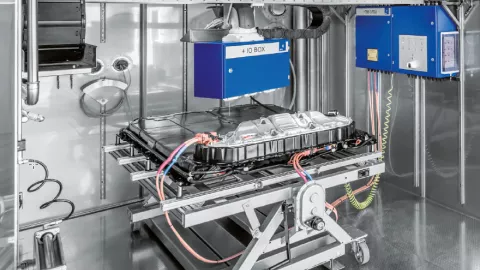

Battery Module Testing

The climatic chambers for battery module testing offer a spacious solution with capacities up to approximately 6 m³ and a temperature range from -40°C to 90°C. Fully integrated into the AVL Battery Module TS™, these chambers allow comprehensive testing of larger battery modules, ensuring accurate simulation of real-world conditions. The integration allows for efficient and precise control, which is critical for evaluating battery performance and safety. With the option of a double side door with window, the chamber can be rotated 90° and has an additional door for even greater flexibility and accessibility during testing.

Tech Center Module - AVL Battery Pack TS™

The AVL Tech Center Modules are versatile container solutions designed for rapid and flexible expansion of testing capabilities. These modular units offer a robust and mobile platform for technical equipment and measurement systems, facilitating the swift setup and adaptation of test infrastructures. The tech center module for battery testing serves as a cost-effective and quickly available solution for climatic testing of battery packs and modules. This module achieves a short delivery time by optimizing a standard solution with proven components, ensuring both efficiency and reliability.

E-Motor and E-Axle Testing

Our climatic chamber for e-motor and e-axle testing is engineered for maximum efficiency and sustainability. Its compact design optimizes space utilization while reducing energy consumption and operational costs. A dedicated air conditioning unit precisely controls temperature and humidity, delivering conditioned air through insulated hoses to maintain a stable testing environment. This setup enables flexible test cell configurations while ensuring highly accurate and repeatable results. Designed for seamless installation and maintenance, the system supports reliable, high-performance testing to meet the most stringent industry standards.

AVL ConsysActive Monoblock

Walk-in climatic chambers are the state-of-the-art solution for battery, fuel cell, and other components testing. However, their large size and volume present certain complexities in project logistics, onsite installation, and commissioning. The ConsysActive Monoblock solution is supplied as a single unit, making it easy to integrate into locally sourced enclosure solutions or retrofit existing ones. The complete cooling, heating, and humidification system is designed for seamless and efficient integration. The climate system is thoroughly tested in advance to ensure optimal integration and performance.

AVL Gas Sampling Unit

Testing a battery cell, module, or pack can damage the unit under test, resulting in various EUCAR hazard levels. When Hazard Level 4 or higher is reached, a large amount of characteristic gases are released. Quick detection of these gases can help prevent damage to the climate chamber or the entire testbed by allowing immediate fire suppression measures. The AVL Gas Sampling Unit analyzes the gas composition in the test chamber in less than ten seconds and takes action to address safety issues. Additionally, it can be integrated with existing safety systems to enhance overall testbed security.

「AVLは、お客様のニーズに適合するテストベンチ設計において、優れた実績と長年の経験を持っています。そのため、AVL Climatic Chambersは、パフォーマンス、安全性、顧客満足度の全てにおいて最高水準を達成しています。」

AVL List GmbH Global Product Manager Peter Kerschenbauer

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL Thermal Testing Solutions – Brochure

Keep Cool, Drive Further.

AVL Climatic Chamber Portfolio – Brochure

Ensuring E-Mobility Reliability Through Extreme Environmental Testing.

AVL ConsysActive Monoblock – Solution Sheet

Streamlined Climate Control - One Unit for All Testing Needs.

Tech Center Module – AVL Battery Pack TS™ – Solution Sheet

The fast track to battery testing excellence.

AVL Gas Sampling Unit – Solution Sheet

Application-driven solution for best-in-class thermal development.

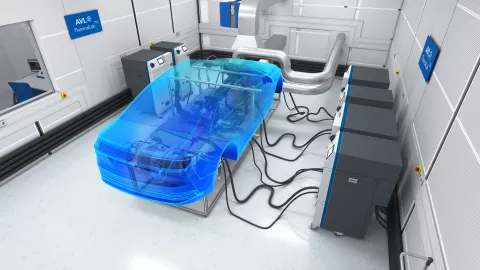

Thermal conditions and environment of Units Under Test have strong impacts on real results in driving. For this reason, the thermal simulation must be as exact as possible – which can be achieved via deployment of high performing media conditioning systems.

AVL ThermalLab™ tests the entire VTMS, including all coolant circuits and the refrigerant cycle, under dynamic conditions using model-based testing. The UUT is the complete VTMS embedded in an emulated vehicle while the environment is fully simulated. The entire system can be tested in the lab under realistic driving and ambient conditions.

バッテリー(モジュール・パック)の試験については、AVLは、試験システム一式、スタンドアロン機器、あるいはターンキー試験ラボ全体を提供しています。

AVLは、バッテリー試験の領域で、試験システム一式とスタンドアロンの機器、ターンキー試験ラボを提供しています。

We offer complete test systems for the testing of modules/packs. Learn more about which hard- and software products are included in our test systems.

AVLには、専用のe-モーター試験システム、ソフトウェア、ツール、工程から構成される広範な製品群があり、これらの最新電動パワートレインを非常に短い期間で試験・妥当性確認を実施します。

個々のコンポーネントに加え、トランスミッションを含む統合型e-アクスルを開発しています。その革新的な能力の一例が、現在市販されている電動パワートレインシステムの中でも最高水準の電力密度を持つ高性能な高速e-アクスルです。

Your success is our goal. This is what we are aiming for and this is how we understand AVL Customer Services since decades. Our goal is not new, but the way how we do it, is constantly evolving.

The primary goal for our AVL Customer Support Teams is, to be a helpful and reliable partner for all kind of questions and issues you might have, when using AVL’s technology.

As a global society, we are pushing hard to achieve a transformation to net-zero-CO₂ but without loosing energy security and our current living standards. The transformation in the mobility will come at cost, which endangers affordable individual mobility in the future. Doing nothing, however, will generate even higher costs.

What kind of cars will we be driving in the future? These and other exciting questions around the topic of "Future Mobility" were addressed by more than 1,000 participants from 25 countries at the international 44th Vienna Motor Symposium. The tenor: Future automobiles will be CO2-neutral.

For his services, Prof. Helmut List was today awarded honorary citizenship of the city of Graz.

AVL generated 1.86 billion Euros in turnover last year – Eleven percent flows into research and development – 60 percent of the turnover is already generated by new technologies.