海洋分野の持続可能性を高めるためのシミュレーションの役割

Published on October 01, 2024 · 11 min read

システムシミュレーションの適用性は、船舶の開発および運用の両方の側面を含む3つのフェーズに見られます。コンセプトと設計のフェーズでは、厳密なパラメータ研究を通じてシステムを最適化し、エンジニアリング要件を満たし、初期のシステム最適化研究、コンセプト比較、システム要件の特定、およびドメインの境界条件の特定を行います。最後に、運用面では、性能最適化、メンテナンス計画、橋梁支援システム、仮想センサー、およびシミュレーターが含まれます。ここでは、モデルを使用してルート最適化、性能向上、オンライン監視、またはエンジニアのシミュレーターでの訓練をサポートすることができます。

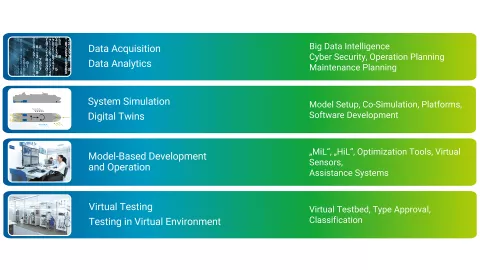

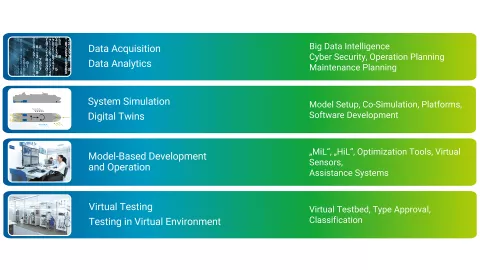

海運業界のデジタルトランスフォーメーションの主要構成要素

統合シミュレーションは、個別のシステムシミュレーションよりもデジタル化に依存しています。最初の前提条件は、正確なデータ取得と、それに続くデータ分析です。これにより、次のシステムシミュレーションの入力が提供されます。デジタルおよびバーチャルツインの生成は、シミュレーションプロセスの鍵となり、エンジニアにユーザーフレンドリーなインターフェースと完全な概要を提供します。これにより、モデルベースの開発が促進され、ユーザーは統合されたシミュレーションブロックを視覚化し、操作することができます。その結果、シミュレーションソリューションは仮想環境での仮想テストを可能にし、船舶の開発や既存モデルの開発において時間と財源を節約します。

シミュレーションソフトウェアの要件

主な要件は、ユーザーインターフェースのモジュラー配置であり、各ブロックが特定のドメインを表します。次に、シミュレーションプラットフォームは過渡的な動作条件を必要とし、船舶の動的解析とそのコンポーネントおよびサブシステムの相互作用の研究を可能にする必要があります。シミュレーションソフトウェアは、必要な詳細レベルを提供します。これらすべては、包括的なマルチドメインおよびマルチフィジックス計算プラットフォームで達成できます。

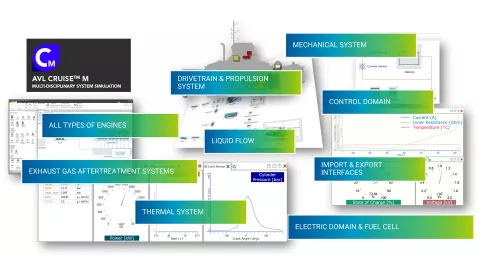

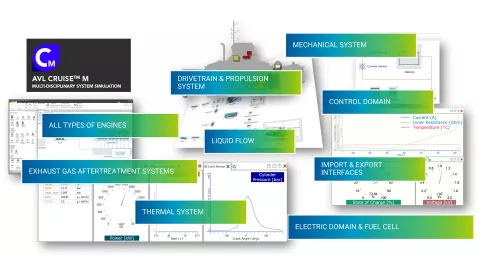

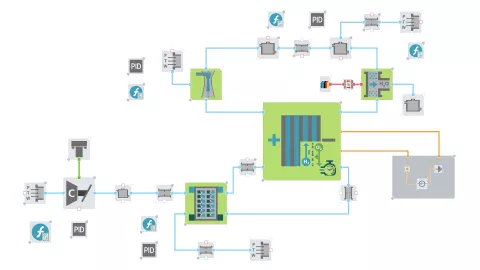

次のセクションでは、統合がシステムレベルのシミュレーションを解放する3つのユースケースを探ります。シミュレーションは、当社のソリューションであるAVL CRUISE™ MおよびModel.CONNECT™によって強化された、特別に開発されたツールチェーンによって実現されます。CRUISE Mは、システム、サブシステム、およびコンポーネントの迅速かつ簡単な仮想分析と最適化のための多用途のシミュレーションプラットフォームです。このソリューションはプラットフォームの中核であり、利用可能な複数のライブラリのおかげで、関連するシミュレーションドメインのモデリングをカバーするモデルの作成を可能にします。

Model.CONNECTは、特定のサブモデルと全体のモデルを接続することができる共同シミュレーション環境です。その結果、コンポーネントは別々の非通信部分ではなく、統一された全体として見られるため、船のような複雑で大規模な構造に理想的です。共同シミュレーションにサードパーティツール(例:Simulinkオープンモデル)を統合し、モデルをより簡単に管理することが可能です。通常、複雑なシステムシミュレーションモデルが生成される場合に適用され、複数のエンジニアリングチームが協力の可能性を高めるためにサブモデルの生成と保守を担当します。

ユースケース 1: リアルタイム対応エンジンモデルによる燃料消費の最適化

船舶の燃料消費は、船のサイズ、船体形状、積載能力、航路、エンジン特性、航行速度など、いくつかの要因に依存します。船舶の燃料消費が多いにもかかわらず、より持続可能な燃料に置き換えることは費用対効果が高くありません。例えば、低品位燃料は大型クルーズ船に1日あたり80,000ガロンで130,000ドルの費用がかかりますが、マリンガスオイルは1日あたり約300,000ドルの費用がかかります。

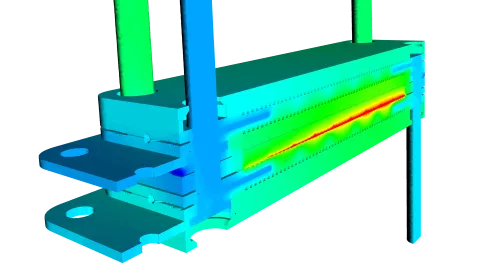

エンジン開発とテストに関連するコストも考慮することが重要です。シミュレーションの使用は、エンジン設計段階の改善、ECU機能の開発およびキャリブレーション、そして現実的な作業サイクルにおける燃料消費量とNOx排出量の推定を支援することが可能です。これには、CRUISE M 1Dおよび0Dエンジンモデルを使用します。HiLシステムに大規模なエンジンモデルを持つことで、開発コストを数百万ドル節約できます。

第18回シンポジウム「持続可能なモビリティ、輸送および発電」で発表された論文では、船舶の推進およびエネルギーシステムのバーチャルツインが作成されました。その後、環境への影響が説明されました。これには、測定データに基づいてN2、O2、CO2、NOX、HCおよびH2Oの経験的および半経験的排出モデルが設定されました。モデルベースの開発のためにクランク角分解エンジンモデルが作成され、現象論的燃焼および排出モデルを通じてエンジンの深い洞察が提供されました。

その後、簡略化されたマップベースのモデルが導出され、計算速度が向上し、航海全体の効率的なシミュレーションに適しています。この船舶構成により、トン数、船舶抵抗、風などのパラメータを考慮して、航海の瞬時および累積排出量を予測することができます。

1 https://www.marineinsight.com/videos/video-how-much-fuel-does-a-cruise-ship-consume/

2 Source: paper “Evaluation of LNG as alternative fuel for large marine engines by means of predictive emission model”

ユースケース2: 船舶の効率の改善に向けた船舶運用のシミュレーション

船内システムは主に熱の形で多くのエネルギーを浪費します。これにより、実際の運航の分析を行い、効果的な船内エネルギー管理を実施することが、燃料消費とその排出量を削減するための重要な要素となります。例えば、ホテルの負荷は発電機や燃料電池(例:固体酸化物燃料電池)からエネルギーを生成することで賄うことができます。さらに、排気ガスに含まれるエンタルピーや内燃機関から放出される熱を利用してプールを温めたり、蒸気を生成したりすることができます。淡水冷却システム、さまざまな水再加熱システム、蒸気回収システムなどのモデルを使用することで、応用範囲はさらに広がります。

このような複雑な相互作用により、いくつかのパラメータに依存して燃料とエネルギーの消費が変動します。したがって、システムシミュレーションは、船自体の3-DOFモデルと組み合わせて船の制御戦略の最適化をサポートすることができます。モデル予測制御アルゴリズムは、目標座標と船の向きを達成するために、舵角と船速を計算し、離散ステップと最小化されたコストで実行します。移動時間とエネルギーまたは燃料消費を含む最適化コスト関数を通じて目的を定義し、重み付けする柔軟なアプローチと適切な船の動力学モデルを組み合わせることが成功の鍵です。この設計の例は以下のビデオで見ることができます。

ユースケース3: 海洋分野におけるハイブリッド化・電動化のトレンドをサポート

船舶のハイブリッド化と電化がますます重要になっている中、CRUISE Mは電動機、燃料電池、バッテリーに関する既存のデータを活用して、ハイブリッドおよび電化されたコンセプトを研究する可能性を提供します。

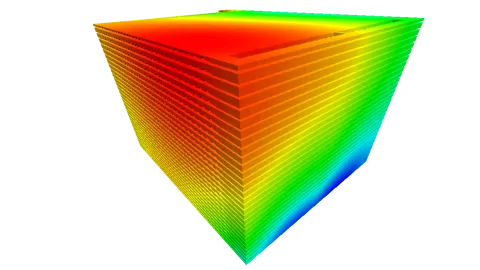

例えば、バッテリーの化学的、電気的、熱的な特性や老化プロセスに関するモデルをいくつかの異なるタイプで記述することができます。これらのモデルは、物理的、経験的、抽象的なモデルの主要なタイプに分けられます。システムレベルでのシミュレーションには、CRUISE Mで2つの異なるモデルタイプが利用可能です。 バッテリーモデルのパラメータ化は、CRUISE Mのバッテリーパラメータ化ウィザードによってサポートされます。このツールは、異なる条件での充電および放電の動的データからモデルパラメータを計算します。

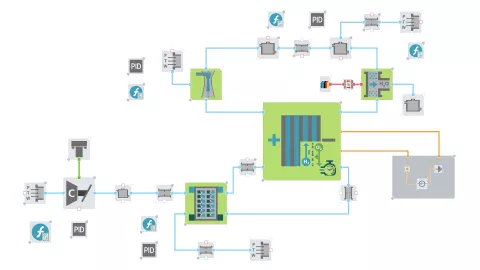

同様に、燃料電池とバランスオブプラントの分析には、さまざまなサブモデルとウィザードが利用可能です。PEMFC(低温および高温)およびSOFCスタックとバランスオブプラントの両方をシミュレートすることができます。以下の図では、燃料電池スタックとバランスオブプラントのアノードおよびカソードブランチのスタンドアロンモデルが示されています。

全体として、海洋分野は資源の節約と海洋システムの最適化に関して大きな変化を遂げ、厳しい環境目標を達成することになります。私たちのシミュレーションソリューションは、船舶を個別のコンポーネントではなく統合されたシステムとしてモデル化することで、変革的なアプローチを提供します。この進歩は、2050年までにネットゼロ目標を達成するために重要です。シミュレーションソフトウェアは、エンジニアに船舶全体のシステムを最適化するためのツールを提供し、効率を高め、汚染を減らし、排出量を最小限に抑えます。仮想化を採用することで、運用パフォーマンスが向上するだけでなく、より持続可能な海運業界に大きく貢献します。

持続可能な海運ソリューションについてさらに読むには、「AVL CRUISE™ Mソフトウェアを使用した旅客船の完全電動ハイブリッド推進システムのモデリングとシミュレーション」という論文をお勧めします。この論文では、水素を主要な電力源としての可能性を探り、マルチフィジックスシミュレーションツールCRUISE Mを使用してシステムの動力学と性能を分析しています。

最新の情報をお見逃しなく

シミュレーションのブログシリーズをご覧ください。今すぐ登録して最新情報を受け取りましょう。

テーマについてさらに詳しく知る

最新のシミュレーションのブログ記事をお見逃しなく

シミュレーションのブログシリーズをご覧ください。今すぐ登録して最新情報を受け取りましょう。