アンモニア - 未来の燃料

- Blog

世界中でエネルギー需要が増加し続ける中、エネルギー産業の長期的な持続可能性に焦点を当てた再考が急務となっています。そのため、近年ではアンモニアが水素と並んで、水素キャリアおよび内燃機関の燃料として使用できる潜在的な代替手段として浮上しています。高速かつ正確な燃焼モデルとして知られるECFM-3Z(Extended Coherent Flamelet Model 3 Zones)は、これまでにいくつかの改良が加えられ、新しい環境に優しい燃料の燃焼をシミュレートするための強力なツールをエンジニアに提供しています。しアンモニア燃焼がECFM-3Zに実装されるのは時間の問題でした。

世界の人口のエネルギー需要が増加し続ける中、エネルギー経済の長期的な持続可能性に焦点を当てた再考がますます必要とされています。現在、この需要は主に化石燃料によって満たされており、その結果として地球温暖化という大きな負の影響が生じています。水素のような非炭素ベースの経済への部分的または完全な移行が提案されていますが、グローバルな水素経済は貯蔵と輸送の困難さから実現可能ではありません。そのため、近年ではアンモニアが水素キャリアおよび内燃機関の燃料として使用できる潜在的な代替手段として浮上しています。

アンモニアは純粋な水素に比べていくつかの利点を提供します。アンモニアはより高い容積密度を持ち、約10バールの圧力で常温で液化することができ、農業(肥料生産)や産業用冷却に広く使用されているため、既に広範なグローバル分配インフラがあります。燃焼限界が狭いため、貯蔵と輸送の安全性も高いです。しかし、その使用には毒性、低い発熱量、遅い層流燃焼速度などの欠点も伴います。

アンモニア使用の主な欠点は高いNO排出量であり、これは燃焼エンジンの排気ガス後処理における触媒還元(SCR)によって処理することができます。効率的な燃焼エンジンは、H2またはディーゼルを補助燃料として使用し、ジェット点火またはディーゼル噴射点火を燃焼開始システムとして使用するデュアル燃料システムでNH3を使用することができます。どちらの場合も、ディーゼルエンジンのように、注入される燃料の量を変えることで負荷を制御することができます。

ECFM-3Z(拡張コヒーレントフレームレットモデル3ゾーン)は、過去にいくつかの改良が行われてきました。アンモニア燃焼に焦点を当てるため、NH3燃焼の拡張について簡単に説明します。NH3の燃焼は発熱反応です:

4NH3+3O2→2N2+6H2O4NH3+3O2→2N2+6H2O

既存の熱NOメカニズム(ゼルドビッチ)はNO排出量を考慮するために使用され、このアプローチに必要な原子種は化学平衡メカニズムを使用して決定されます。

新しく適応されたECFM-3Zは、異なる燃焼システムに使用できます:純粋なNH3スパーク点火システム、ディーゼル燃料の自己着火によって点火されるNH3システム、または主燃料としてNH3/H2/CH4(または他の炭化水素燃料)を使用し、ディーゼルで点火されるシステムの組み合わせです。

この運転コンセプトでは、燃料噴射のシミュレーションが必要であり、液体ディーゼル噴射はラグランジュスプレーモデルを使用してシミュレーションされました。シリンダー内にはアンモニアが気体の状態で(空気と予混合された状態で)存在していました。噴射後、ディーゼルの自己着火によって放出される熱が燃焼室内でアンモニアの燃焼を引き起こします。エンジン内での一連のイベント、噴射、着火、燃焼の全過程は、図2のアニメーションに示されています。

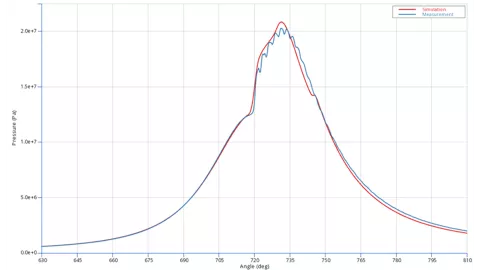

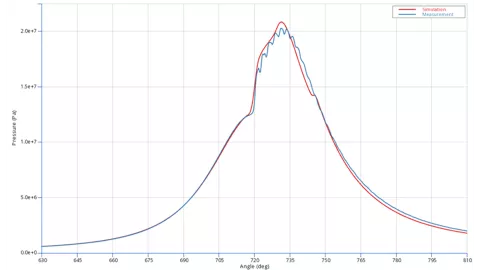

図3は、3D CFD(AVL FIRE™ M)シミュレーションと測定から得られたシリンダー平均圧力トレースの一致を示しています。

FIRE MにおけるECFM-3Zモデルは、ユーザーに対してアンモニア燃焼を迅速かつ効率的に、そして堅牢にシミュレーションする可能性を提供します。シミュレーション時間は、ECFM-3Zモデルを使用した従来のガソリンおよびディーゼルエンジンシミュレーションと同等であり、GGPRシミュレーションよりもはるかに速いです。結果は参照データと良好な一致を示しています。

FIRE Mのソリューションは、スパーク点火からマイクロパイロット圧縮点火、および外部燃焼促進剤による自己着火など、すべての一般的な点火をサポートします。これにより、新しいECFM-3Zモデルは現在検討されているすべてのアンモニア燃焼概念に適用可能となります。

最新の情報をお見逃しなく

シミュレーションのブログシリーズをご覧ください。今すぐ登録して最新情報を受け取りましょう。

テーマについてさらに詳しく知る

The focus of this part of our event series is on the promising potential of alternative fuels for combustion engines. Green hydrogen and ammonia, for example, enable mobility in sectors that are difficult to electrify and at the same time significantly reduce greenhouse gas and pollutant emissions.

最新のシミュレーションのブログ記事をお見逃しなく

シミュレーションのブログシリーズをご覧ください。今すぐ登録して最新情報を受け取りましょう。