N E X T L E V E L I N T E L L I G E N T A U TO M AT I O N

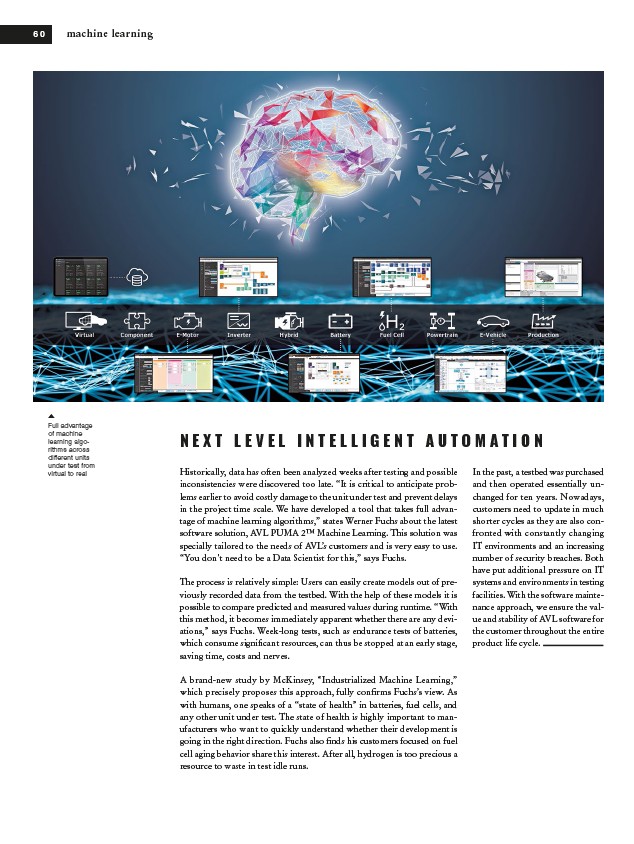

Full advantage

of machine

learning algorithms

across

different units

under test from

virtual to real Historically, data has often been analyzed weeks after testing and possible

inconsistencies were discovered too late. “It is critical to anticipate problems

earlier to avoid costly damage to the unit under test and prevent delays

in the project time scale. We have developed a tool that takes full advantage

of machine learning algorithms,” states Werner Fuchs about the latest

software solution, AVL PUMA 2™ Machine Learning. This solution was

specially tailored to the needs of AVL’s customers and is very easy to use.

“You don't need to be a Data Scientist for this,” says Fuchs.

The process is relatively simple: Users can easily create models out of previously

recorded data from the testbed. With the help of these models it is

possible to compare predicted and measured values during runtime. “With

this method, it becomes immediately apparent whether there are any deviations,”

says Fuchs. Week-long tests, such as endurance tests of batteries,

which consume significant resources, can thus be stopped at an early stage,

saving time, costs and nerves.

A brand-new study by McKinsey, “Industrialized Machine Learning,”

which precisely proposes this approach, fully confirms Fuchs’s view. As

with humans, one speaks of a “state of health” in batteries, fuel cells, and

any other unit under test. The state of health is highly important to manufacturers

who want to quickly understand whether their development is

going in the right direction. Fuchs also finds his customers focused on fuel

cell aging behavior share this interest. After all, hydrogen is too precious a

resource to waste in test idle runs.

In the past, a testbed was purchased

and then operated essentially unchanged

for ten years. Nowadays,

customers need to update in much

shorter cycles as they are also confronted

with constantly changing

IT environments and an increasing

number of security breaches. Both

have put additional pressure on IT

systems and environments in testing

facilities. With the software maintenance

approach, we ensure the value

and stability of AVL software for

the customer throughout the entire

product life cycle. �

6 0 machine learning