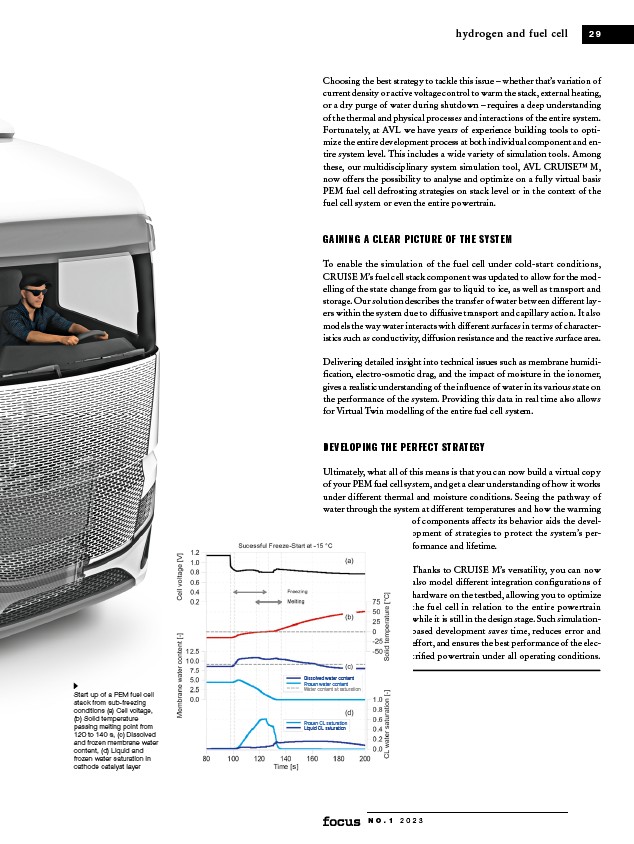

Start up of a PEM fuel cell

stack from sub-freezing

conditions (a) Cell voltage,

(b) Solid temperature

passing melting point from

120 to 140 s, (c) Dissolved

and frozen membrane water

content, (d) Liquid and

frozen water saturation in

cathode catalyst layer

hydrogen and fuel cell 2 9

Choosing the best strategy to tackle this issue – whether that’s variation of

current density or active voltage control to warm the stack, external heating,

or a dry purge of water during shutdown – requires a deep understanding

of the thermal and physical processes and interactions of the entire system.

Fortunately, at AVL we have years of experience building tools to optimize

the entire development process at both individual component and entire

system level. This includes a wide variety of simulation tools. Among

these, our multidisciplinary system simulation tool, AVL CRUISE™ M,

now offers the possibility to analyse and optimize on a fully virtual basis

PEM fuel cell defrosting strategies on stack level or in the context of the

fuel cell system or even the entire powertrain.

GAINING A CLEAR PICTURE OF THE SYSTEM

To enable the simulation of the fuel cell under cold-start conditions,

CRUISE M’s fuel cell stack component was updated to allow for the modelling

of the state change from gas to liquid to ice, as well as transport and

storage. Our solution describes the transfer of water between different layers

within the system due to diffusive transport and capillary action. It also

models the way water interacts with different surfaces in terms of characteristics

such as conductivity, diffusion resistance and the reactive surface area.

Delivering detailed insight into technical issues such as membrane humidification,

electro-osmotic drag, and the impact of moisture in the ionomer,

gives a realistic understanding of the influence of water in its various state on

the performance of the system. Providing this data in real time also allows

for Virtual Twin modelling of the entire fuel cell system.

DEVELOPING THE PERFECT STRATEGY

Ultimately, what all of this means is that you can now build a virtual copy

of your PEM fuel cell system, and get a clear understanding of how it works

under different thermal and moisture conditions. Seeing the pathway of

water through the system at different temperatures and how the warming

of components affects its behavior aids the development

N O . 1 2 0 2 3

of strategies to protect the system’s performance

and lifetime.

Thanks to CRUISE M’s versatility, you can now

also model different integration configurations of

hardware on the testbed, allowing you to optimize

the fuel cell in relation to the entire powertrain

while it is still in the design stage. Such simulationbased

development saves time, reduces error and

effort, and ensures the best performance of the electrified

powertrain under all operating conditions.

Dissolved water content

Frozen water content

Water content at saturation

Frozen CL saturation

Liquid CL saturation