e-mobility 2 1

N O . 1 2 0 2 3

While every component must meet

the highest demands, it is integrated

solutions that deliver the biggest

ROI. They do this by reducing

costs, development time and effort,

and delivering the highest efficiency,

performance and integrability.

Other advantages are smaller dimensions,

lower weight, reduced

interfaces, and improvements regarding

electromagnetic radiation.

At AVL we are leading this new era

of mobility, thanks to our decades

of experience and our close relationships

with the academic institutions

driving knowledge in this

area. But it is our product and solution

portfolio that delivers real

results. Whether it’s the e-motor,

the transmission, the e-axle, or the

power electronics and software, we

turn knowledge into motion.

E-AXLES – A MODULAR,

LOW-COST APPROACH TO

E-MOBILITY

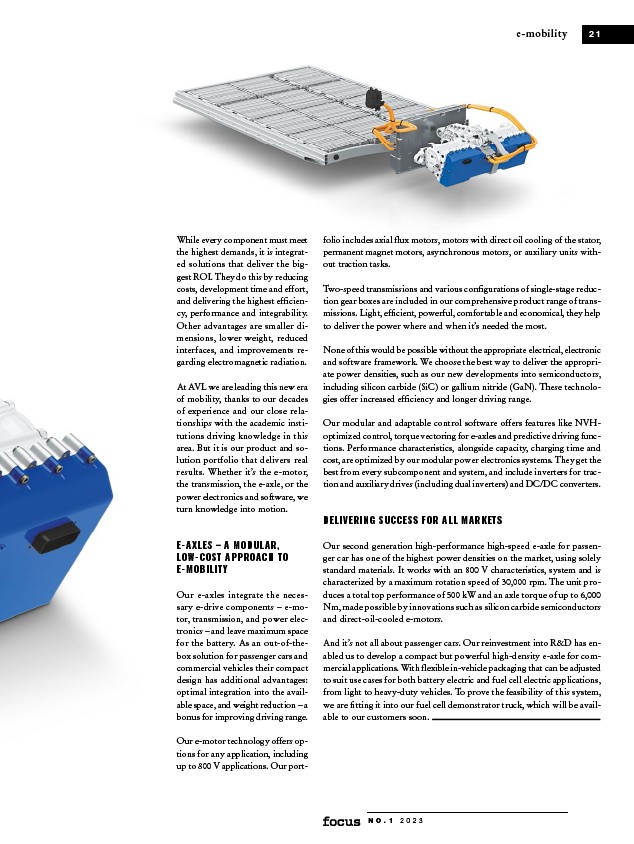

Our e-axles integrate the necessary

e-drive components – e-motor,

transmission, and power electronics

– and leave maximum space

for the battery. As an out-of-thebox

solution for passenger cars and

commercial vehicles their compact

design has additional advantages:

optimal integration into the available

space, and weight reduction – a

bonus for improving driving range.

Our e-motor technology offers options

for any application, including

up to 800 V applications. Our portfolio

includes axial flux motors, motors with direct oil cooling of the stator,

permanent magnet motors, asynchronous motors, or auxiliary units without

traction tasks.

Two-speed transmissions and various configurations of single-stage reduction

gear boxes are included in our comprehensive product range of transmissions.

Light, efficient, powerful, comfortable and economical, they help

to deliver the power where and when it’s needed the most.

None of this would be possible without the appropriate electrical, electronic

and software framework. We choose the best way to deliver the appropriate

power densities, such as our new developments into semiconductors,

including silicon carbide (SiC) or gallium nitride (GaN). These technologies

offer increased efficiency and longer driving range.

Our modular and adaptable control software offers features like NVH-optimized

control, torque vectoring for e-axles and predictive driving functions.

Performance characteristics, alongside capacity, charging time and

cost, are optimized by our modular power electronics systems. They get the

best from every subcomponent and system, and include inverters for traction

and auxiliary drives (including dual inverters) and DC/DC converters.

DELIVERING SUCCESS FOR ALL MARKETS

Our second generation high-performance high-speed e-axle for passenger

car has one of the highest power densities on the market, using solely

standard materials. It works with an 800 V characteristics, system and is

characterized by a maximum rotation speed of 30,000 rpm. The unit produces

a total top performance of 500 kW and an axle torque of up to 6,000

Nm, made possible by innovations such as silicon carbide semiconductors

and direct-oil-cooled e-motors.

And it’s not all about passenger cars. Our reinvestment into R&D has enabled

us to develop a compact but powerful high-density e-axle for commercial

applications. With flexible in-vehicle packaging that can be adjusted

to suit use cases for both battery electric and fuel cell electric applications,

from light to heavy-duty vehicles. To prove the feasibility of this system,

we are fitting it into our fuel cell demonstrator truck, which will be available

to our customers soon.