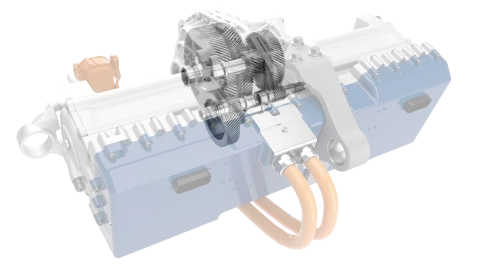

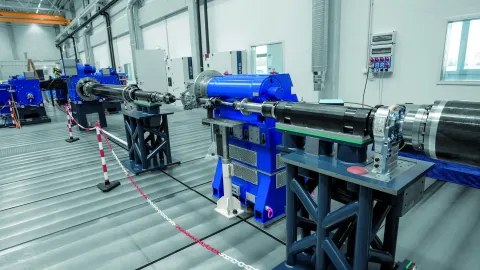

Our transmission test systems are engineered to validate a wide range of transmissions, addressing varying types, speeds, and power classes. The main challenge lies in integrating an ICE or e-motor within a compact, close axle arrangement. The AVL drive unit is designed to meet the necessary speed and torque requirements while ensuring compatibility with the available installation space. Our solutions are capable of handling the variability of e-axles in both co-axial and offset configurations, along with the intelligent mechanical connection of e-motors to transmissions.

The optimization of the design and validation process is a key benefit, as our systems allow for early-phase transmission testing, even without a fully developed propulsion unit. This reduces the likelihood of design changes in later development stages. In addition, AVL PUMA 2™ automation software adds significant value to the testing process by synchronizing data from all connected devices. This results in precise measurement and control, enabling faster transmission system development through various test types, such as transient, time-lapse, and road load simulation tests.

Nothing is more constant than change. As transmission architectures evolve, so must our testing solutions. With AVL’s expertise and reliable systems, our customers can confidently validate performance and focus on what matters most – innovation and development.”

– Dr. Klaus Pfeiffer, System Line Manager, AVL Deutschland GmbH