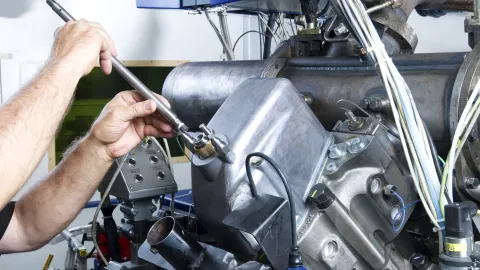

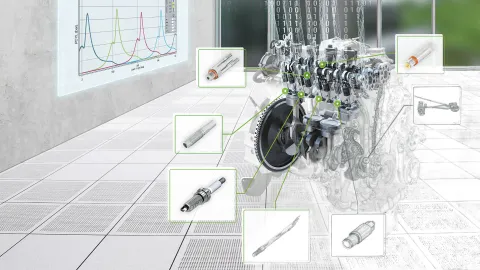

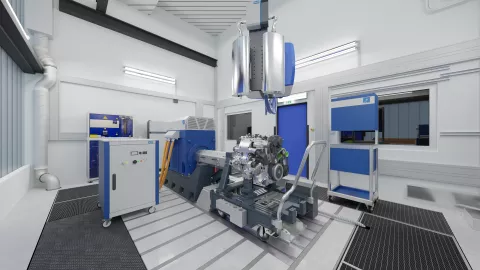

We offer a comprehensive portfolio of engine test systems that address a broad spectrum of research and development challenges in the automotive and mobility sectors. Our solutions are tailored to support the development of both internal combustion engines (ICE) and hybrid propulsion systems, ensuring high precision and reliability across all stages of the development lifecycle. Our test systems are equipped to handle a wide range of complex tasks, including:

-

Hardware Verification

-

System Integration, including Hybrid Components

-

ECU / HCU Calibration

-

Hybrid Operating Strategy Implementation

-

Fuel Consumption Optimization

-

Electric Charge Determinations.

-

Steady-State and Dynamic Duty Tests

-

Engine Response Optimization

-

Exhaust Emissions Development and Homologation

Our advanced engine test systems offer unmatched accuracy and flexibility to solve even the most complex development challenges. With our technology, engineers can accelerate innovation while ensuring optimal performance and regulatory compliance.

At AVL, we are committed to driving innovation in engine and hybrid testing. Our cutting-edge technology empowers our customers to overcome today’s development challenges while preparing them for the future of mobility."

– Michael Messner, Global Business Unit Manager, AVL List GmbH