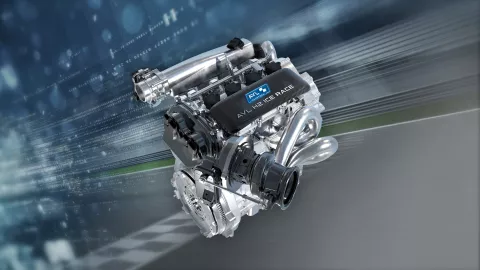

We go beyond supplying test equipment – we specialize in high-tech engineering of powertrains and propulsion systems. Our innovative, user-oriented solutions are always tailored to the future requirements of vehicle development, spanning everything from individual components to complete vehicles. This approach positions us as more than just a provider of testing equipment; we are a trusted partner from the earliest planning stages, through needs assessment, to the delivery of focused, high-performance solutions.

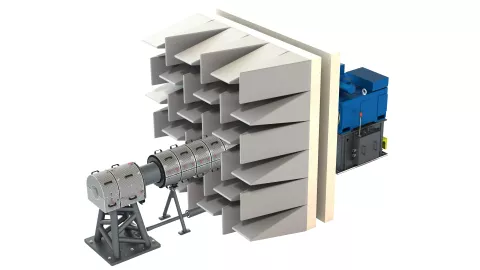

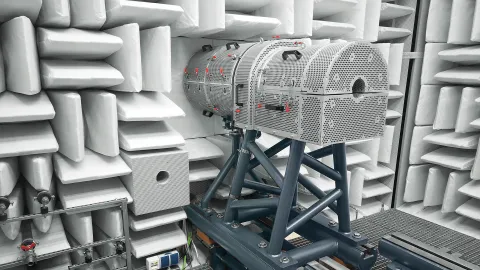

NVH testbed solutions are meticulously designed to meet the highest standards of acoustic performance. These systems are optimized to minimize sound attenuation from noise-generating components and reduce sound reflections from the structure of the test system itself. This ensures that the primary focus of every acoustic measurement is the unit under test (UUT).

Additionally, we are committed to adhering to strict acoustic standards, guaranteeing that each NVH test system achieves the agreed NVH targets. To ensure peak performance, all components are carefully aligned, and the system undergoes a rigorous acceptance analysis for validation. This comprehensive approach allows us to deliver precision-engineered solutions that meet and exceed industry expectations.

NVH Solutions for E-Motor

Our advanced NVH test systems for validating e-motors are designed to support all UUT variants, enabling precise and reliable testing. These systems create tailored development environments that address NVH challenges quickly, efficiently, and sustainably. Depending on your specific requirements, our NVH solutions are categorized into three core setups: premium, precision, and efficiency. Each setup is engineered to optimize the testing process across all UUT types, ensuring superior acoustic performance and accelerating time-to-market. With AVL's expertise, you can achieve high-quality results that meet the increasing demands of modern electric mobility. → Learn more

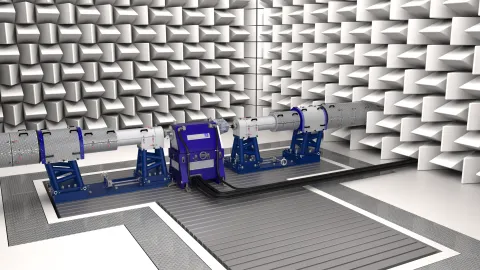

NVH Solutions for E-Axle

Leveraging our extensive experience in NVH powertrain testing, we provide high-quality acoustic environments specifically designed for e-axle validation. Every component, including the acoustic enclosures, is developed with simulation-optimized engineering to minimize sound reflections and ensure exceptional NVH performance. Our systems emphasize user convenience, featuring movable loading units that allow seamless adaptation to UUTs of various sizes. This streamlined and flexible design simplifies workflows, enhances testing efficiency, and supports precise acoustic measurements for superior e-axle performance. → Learn more

NVH is not only about improving noise on vehicles and powertrains, but moreso it’s about setting up a brand sound, inspiring passengers of modern cars during their ride. With our NVH test systems and solutions we provide a high-class development platform for vehicle and component sound development to drive the pleasure of tomorrows mobility.”

– Joachim Schmidt, Department Manager, AVL List GmbH

NVH testing in e-mobility, which stands for Noise, Vibration, and Harshness testing, is essential for optimizing the comfort and sound quality of electric vehicles. AVL offers advanced testbeds, simulation technologies and engineering services to measure, analyze and optimize NVH characteristics. Their comprehensive testing solutions cover everything from individual components to complete vehicle systems, addressing parameters such as high-frequency noise, wind and road noise and structural integrity. AVL helps manufacturers meet stringent acoustic standards, improve vehicle comfort, and create a distinctive sound profile for electric vehicles.

It makes sense to do NVH testing in all development stages, starting from conceptualization over to simulation models, and finally to the complete product. In early development phases, NVH topics can be addressed easier in accordance to the overall project goals. Late involvement of NVH development typically leads to high costs in redesign and restrictions in solutions findings before start of production. AVL provides NVH Test Systems and simulation tools for single components, such as e-motors and inverters, over to component assemblies, such as e-axles, and finally for the fully assembled vehicle.

NVH testing is crucial for electric vehicles because it helps improve driver and passenger comfort by minimizing unwanted noise and vibrations, which are more noticeable in quieter electric drivetrains.

Common challenges include managing high-frequency noise from electric motors, reducing wind and road noise, and ensuring the structural integrity of lightweight vehicle components.

AVL provides a range of NVH testing solutions, including test systems for e-motors, e-axles, and complete vehicles, designed to meet stringent acoustic standards and optimize vehicle sound quality. Furthermore, AVL supports in any development and production stage of a vehicle and its components with tailored testing solutions, from highly flexible R&D test systems to automated end of line monitoring systems.

AVL NVH test systems are designed to achieve ultra-low background noise levels for highest signal and noise ratios.

- Seamlessly integrated test bed automation, data acquisition and simulation tools that help to reduce development time significantly.

- Simulation of real dynamic operating conditions as they appear on the road.

- Supporting a big variety of industries ranging from high speed (e.g. 36,000 rpm) to high torque (eg. 50 kNm) application.

- Flexible and variable design for quick adjusting to different powertrain systems

- Always up to date with the latest NVH requirements and norms

- With an installed base of currently over 200 NVH test beds worldwide, AVL underlines our strong commitment towards NVH development and testing.

- AVLs customers benefit of the strength and expertise of a big global player and, at the same time, having the comfort of a reliable local team. Efficient project teams cooperate in a mix of local and global engineers, each with high expertise in their own field: Project managers, layout designers, NVH engineers and many more.

- More than 25 years of experience in NVH development

- More than 120 engineers are working with NVH topics daily, in vehicle development, simulation and test system design.

- AVL continuously keeps up with the latest NVH development trends. AVLs high-class development platform is industry proven and highly adaptive for specifically tailored NVH testing solutions.

- AVL provides NVH Test Systems and simulation tools for single components, such as e-motors and inverters, over to component assemblies, such as e-axles, and finally for the fully assembled vehicle.

- AVL provides testing solutions for any stage in the vehicle development process, starting from conceptualization over to simulation models, and finally to the complete product.

AVL’s NVH testing solutions help manufacturers meet stringent acoustic standards, ensuring compliance with regulatory requirements and enhancing overall vehicle comfort and sound quality.

AVL offers a comprehensive software portfolio for simulation (e.g. AVL EXCITE™), automation (PUMA™) and data acquisition and analysis (AVL CAMEO™ , AVL Concerto™, X-ion™ for NVH). Furthermore, AVLs complete testing solutions serve to acoustically validate and optimize components and whole vehicles over their total development and production cycle.

Simulation supports NVH testing by allowing engineers to predict and analyze noise, vibration, and harshness characteristics early in the design process, reducing the need for multiple physical prototypes. It enables virtual prototyping and integration of test and simulation data, enhancing the accuracy of NVH predictions. This approach is cost-effective and helps ensure regulatory compliance while improving overall design. Here, AVL EXCITE™ supports the modeling of components, subsystems and complete drive units with varying levels of detail. One of EXCITE's core competences is the calculation of structure-borne and airborne noise of powertrain units. Evaluation tools such as Operational Deflection Shape (ODS), Numerical Transfer Path Analysis (NTPA) and Modal Contribution Factors (MCF) give you answers to the causes and sources of excitation and vibration.

AVL provides testing equipment which is integrated to semi or full anechoic chambers according to ISO3745. The low background noise level allows highly accurate sound power measurements and NVH development. The testing equipment is fully compatible with the required quantity and positions of the microphones according to ISO3744 and ISO3745.

AVL is known for its consistent integration of normative specifications, established industry solutions and special customer requests into the overall concept of the test system.