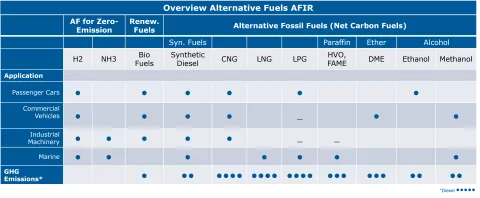

The need for cleaner vehicles, industrial machinery, marine ships, etc. when it comes to exhaust emissions, especially CO2, draws a distorted image for the future of ICE-based propulsion systems. Fuels such as natural gas, biofuels, alcohol fuels, hydrogen, and e-fuels are – depending on their application – promising alternatives for reducing emission and greenhouse gases. However, the increased variety of fuel options for ICE-based propulsion systems makes development and testing even more challenging, due to a significant increase in the complexity of the test facility installation. We have the right test system solutions available, which address the extended requirements for supply, measurement, and testing technology in combination with enhanced safety aspects.

As part of the 2015 Paris Agreement, 196 countries committed to substantially reducing their greenhouse gas emissions to limit global warming. In 2021, the international community agreed to explicitly mention the burning of fossil fuels as the primary cause of climate change at the COP26 in Glasgow for the first time. Sustainable and near-zero carbon alternative fuels will be necessary to halve greenhouse gas emissions from hard-to-abate sectors, such as shipping, aviation, and trucking by 2050.

Alternative fuels are gaseous or liquid fuels for internal combustion engines that are created by turning renewable electricity into chemically bound energy carriers. Examples include hydrogen, methane, methanol, oxymethylenether (OME), dimethylether (DME), or Fischer-Tropsch fuels. Using these e-fuels can potentially help convert today’s internal combustion engines to effective carbon-neutral propulsion systems with zero-impact emissions.

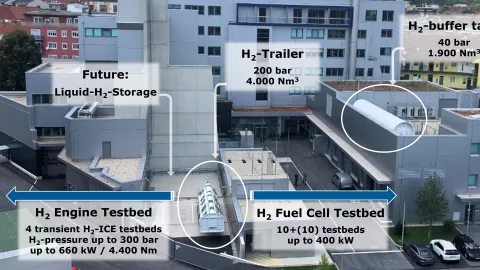

Fuel Supply Infrastructure

To run engines on testbeds with alternative fuels, a suitably designed and sized, and correctly located storage and supply infrastructure is key. AVL headquarters in Graz has housed such an infrastructure for many years to support in-house test factory operation. Visitors are welcome to see how this infrastructure was successfully installed in a critical environment.

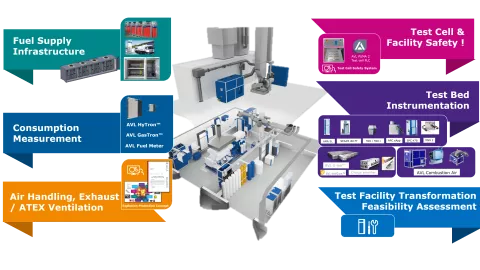

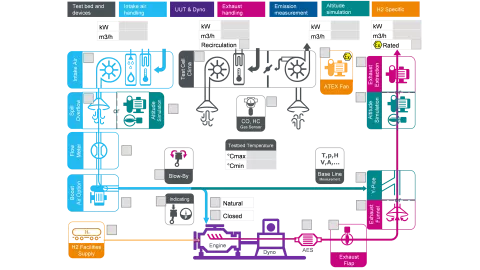

Upgrade / Transformation of Test Facilities

Having engines operated with new, alternative fuels on the testbed means that an extensive number of modifications and extensions need to be considered. Fuel consumption measurement, emission measurement instrumentation, combustion air, etc., and additional test cell safety measures are typical examples that need to be taken into account. We can help you upgrade these, and help you transform existing test cells for operation with new, alternative fuels.

No matter which alternative fuel will be used to operate internal combustion engines on testbeds, we have the right testing solution. Based on our advanced product portfolio, comprehensive skills in designing, installing, and commissioning test facilities, and supporting customers during operation, we are the perfect partner for the successful implementation of your planned test facility extension.

We strongly believe in the importance of alternative fuels and their contribution to a sustainable environment for present and future generations.”

-- Johannes Kregar and Maria Santos, MTA Advanced Applications

A gas conditioning and consumption solution for hydrogen and other gaseous fuels. Learn more about this dedicated product to safely supply and condition gases for the testbed usage.

The AVL H2D is a high-end hydrogen mass spectrometer to support the development of fuel cells and H2 internal combustion engines (ICE). It measures H2 and optionally N2, O2, H2O and CO2.

AVL PUMA 2™ is the global industry standard for testbed automation. It is suitable for electrified testbed types as well as for conventional test environments.

To meet the special requirements in production testing, we offer a specialized portfolio.

With increasingly strict emissions restrictions across the world, and demand for affordable vehicles with low fuel consumption that do not sacrifice comfort, the automotive industry is facing enormous challenges.

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

AVL’s hybrid and engine test systems are highly flexible development environments for testing internal combustion engines and their hybrid components.

Transform your e-mobility analysis with AVL CONCERTO 6™, featuring fast data access, AI-driven technologies, advanced visualizations and calculations, and auto-generated reports for superior performance and precise insights.

To make your future propulsion system ready for this wide range of alternative fuels, we offer a portfolio of certified emission measurement equipment, software, and calibration tools. Easily adaptable and certified for alternative fuels, they help you test, optimize, and approve various fuel types to get the best out of your propulsion system. Our engineering experts are also on hand to support you with independent studies and recommendations on strategies regarding future energy, fuels, and mobility. In addition, we ensure utmost efficiency by adding simulation to all development tasks. This enables highly accurate analyses and proficient optimization of the combustion system, giving you a better idea of the impact on both combustion efficiency and pollutant formation. Which helps you optimize the entire combustion system more efficiently.

TARGET APPLICATION

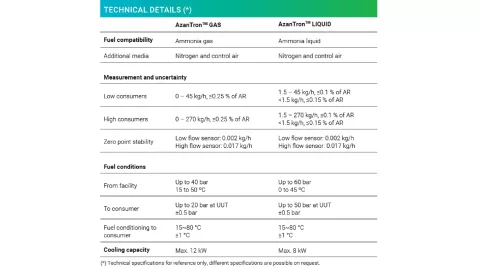

For conditioning the temperature and pressure as well as measuring the flow of gaseous or liquid ammonia supplied to a consumer. AVL AzanTron is ideal for applications such as single or multi-cylinder engines, solid oxide fuel cells and industrial processes.

SAFETY

Guaranteed leak-tight connections and safety integrity components prevent the uncontrolled release of ammonia. The system includes automatic fill and drain, flush and shutdown routines.

RELIABLE CONSUMPTION MEASUREMENT

AVL AzanTron™ is the integrated solution for the safe supply and precise measurement of both gaseous and liquid ammonia consumption.

With advanced media conditioning, NH3-compliant high-quality instrumentation and robust flow measurement, it ensures highly reproducible fuel measurement results, even during transient testing. Sensor fusion technology provides an extensive turndown ratio without the need for manual switching, while continuous monitoring and conditioning of operating parameters maintains the required thermodynamic state of ammonia.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

10

affiliates with expertise in alternative fuels facility engineering

4

available test cells with alternative fuel testing capabilities at AVL Graz

> 10

design and development teams with H2 ICE experience

> 20

years of successful projects involving gas and biofuels

WEBINAR - Hydrogen has the potential to be used to facilitate the shift towards zero CO2 and zero impact pollutant emissions in transport, marine, and industrial internal combustion engine (ICE) applications.

AVL, TUPY and partners developed and tested a hydrogen high-pressure direct injection (H2-HPDI) engine, achieving a brake thermal efficiency (BTE) of over 50 %, with potential improvements up to 52 %. The engine's performance is comparable to diesel engines, with similar full load power and transient torque characteristics.

As we have been celebrating 75 years of Reimagining Motion throughout this year, we are thrilled to release our new brand movie, commemorating this remarkable milestone of technology excellence and innovation.