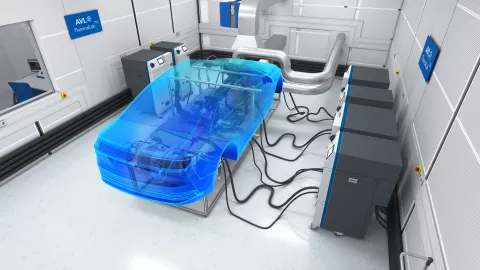

To accurately simulate extreme driving conditions on the testbed, thermal conditioning systems must create extreme media conditions. This capability is essential for conducting precise and effective tests.

Efficiency on the testbed is significantly enhanced by the timely establishment of initial conditions. Oil and coolant conditioning systems facilitate rapid cooling of the UUT at the conclusion of each test cycle. This rapid cooling process allows for an increased number of tests, such as cold start tests, to be conducted within a given time frame.

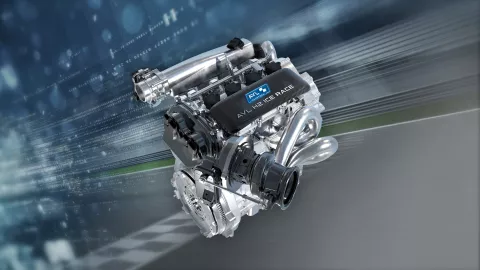

Key Features of our media conditioning systems:

- Modular Design: Our systems are designed to be modular, offering exceptional functional expandability to meet diverse testing needs.

- Compact and Mobile: The compactness of our systems ensures high mobility and versatility on the testbed, making them easy to integrate and use.

- Robustness and Durability: Engineered for maximum dynamics and control quality, our systems are exceptionally robust and built to last. With an installed base of over 4,000 systems, their quality and durability are well-proven.

AVL media conditioning systems are optimized for dynamic performance and control quality. They enable precise simulations and enhance the overall efficiency of the testbed by allowing more tests to be conducted in less time.

|

ICE |

Transmission |

Battery |

E-Motor |

Power |

Fuel Cell |

|

|

Coolant |

✓ |

– |

✓ |

✓ |

✓ |

✓ |

| Boost Air |

✓ |

– |

– |

– |

– |

✓ |

| Oil |

✓ |

✓ |

✓ |

✓ |

✓ |

– |

| Intake Air |

✓ |

– |

– |

– |

– |

✓ |

| Exhaust Back Pressure |

✓ |

– |

– |

– |

– |

✓ |

| Altitude Simulation |

✓ |

– |

– |

– |

– |

✓ |

AVL elevates thermal testing with the AVL ConsysCool Dynamic and AVL Model.Connect. This combination enables hardware-in-the-loop testing of thermal systems, accelerating development from road testing to a controlled laboratory environment."

– Andreas Baumgartner, Global Product Manager Conditioning Systems, AVL List GmbH