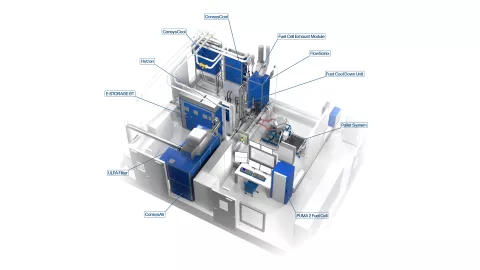

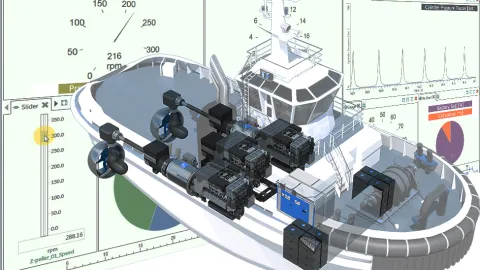

Our integrated solution can range from light duty (nominal FCS power from 30 kW up to 160 kW) to heavy duty (nominal FCS power up to 400 kW) applications. It fulfils all required control and measurement accuracies.

The integrated solution supports a full range of testing needs including:

- Fuel consumption (e.g., EU2017/1151)

- Emission (e.g., SAE J2578)

- Performance (e.g., GB/T24554-2019)

- Fuel cell control unit calibration

- Benchmarking

Model-Based Calibration

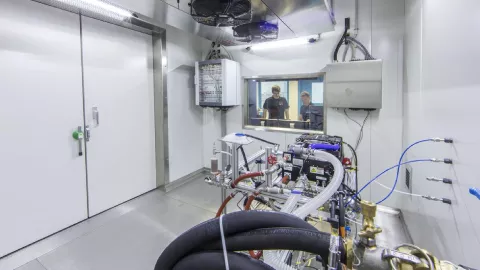

Interface directly with the fuel cell control unit. Assisted by comprehensive simulation models, the fuel cell system can behave just like in the vehicle. Calibrate the full range of performance, consumption, and durability in a safe and repeatable environment.

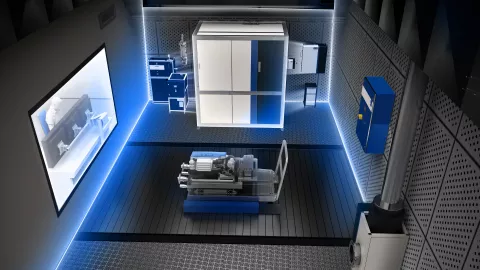

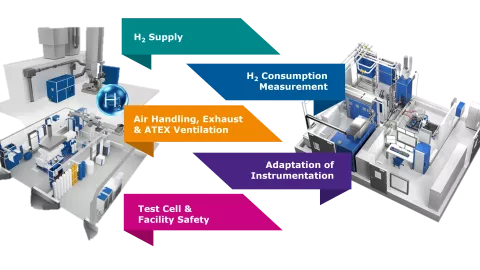

Tailored Modularity and Integration

AVL offers application optimized testing solutions based on modular test equipment. Be ready for future changes with flexible and upgradable devices. Equipment and components can be shared, relocated, and used across entire test fields.

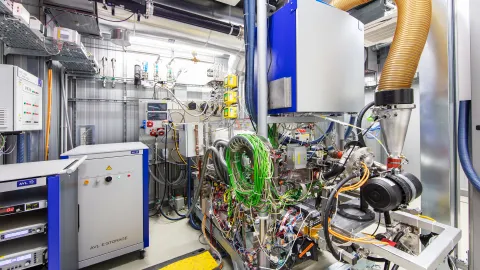

Degradation Toolchain

Fully integrated tools to track and predict fuel cell stack degradation based on specified operating conditions and measurements. Lifetime and durability of prototype designs can be directly predicted and optimized in real-time.

Test Field Consistency

As part of AVL’s tool chain, test procedures and results are consistent across the entire test field. The full capabilities of the test beds can be utilized by both newcomers and fuel cell experts.

Whether you’re new to fuel cell development and looking for your first test bed, or you’re building a custom test field with dozens of test units, we can use our decades of fuel cell expertise to provide the solution that will work for you now and in the future.

– Jeremy Leung, Lead Engineer Fuel Cell Testing Solutions, AVL