One of the biggest challenges in today's rolling stock market is to enable catenary-free operation without relying on internal combustion engine technology. While conventional trainsets and locomotives are powered by either overhead power lines or diesel fuel, battery and fuel cell powered trains are gaining traction in the rail market.

To support the development and validation of these technologies, know-how transfer from the automotive industry is needed. This is where AVL comes in and enables this through our testing and validation solutions.

Maintainance, repair and overhaul (MRO) is an important topic for railway operators and state railways. The need to test all traction motors of available rolling stock can be a challenge, and often comes with much time off the tracks. To increase speed and reliability, a fast and automated approach is the right way to go. With test systems, which allow for streamlined testing of conformity of production, a gain in overall speed or MRO processes can be achieved. This also means less time for rolling stock in the depot, more time on track and a smoother operation.

To increase efficiency in the next generation of train propulsion systems, such as traction motors, traction transmissions, or diesel-electric engine, testing can be the key to streamlined development. Complete test systems including testbed automation and a comprehensive toolchain enable customers to find problems and do functional testing in an efficient way. Moreover, the shift to catenary free operation creates the need for traction via battery or hydrogen fuel cell systems. Here, we can look back on a vast expertise in terms of electrification in the automative sector.

Using existing know-how and technologies of the automotive industry, and applying them in railway applications is the way to go forward. Our solutions are cut out for your challenges.”

– Sascha Heinecke, Director Sales, Industry Solutions

Our solutions cater to all types of rolling stock, from electrical multiple units (EMUs) like high-speed and commuter rail, to diesel-electric multiple units (DMUs). We also cover light rail, trams, metro applications as well as locomotives, and track-and-maintenance vehicles. Our technology ensures optimal performance and reliability across all these applications – enabled by our testing solutions.

We have developed a highly reliable and robust test system that improves product quality assurance (OK/NOK) for traction motors. This innovative system streamlines test processes, significantly reducing test time and total cost of ownership. Unlike conventional e-motor end-of-line (EoL) testing solutions, our system eliminates the need for a dynamometer by measuring forces directly. The entire process - from mounting the e-motor to completing the test - takes less than a minute and delivers results at a fraction of the cost.

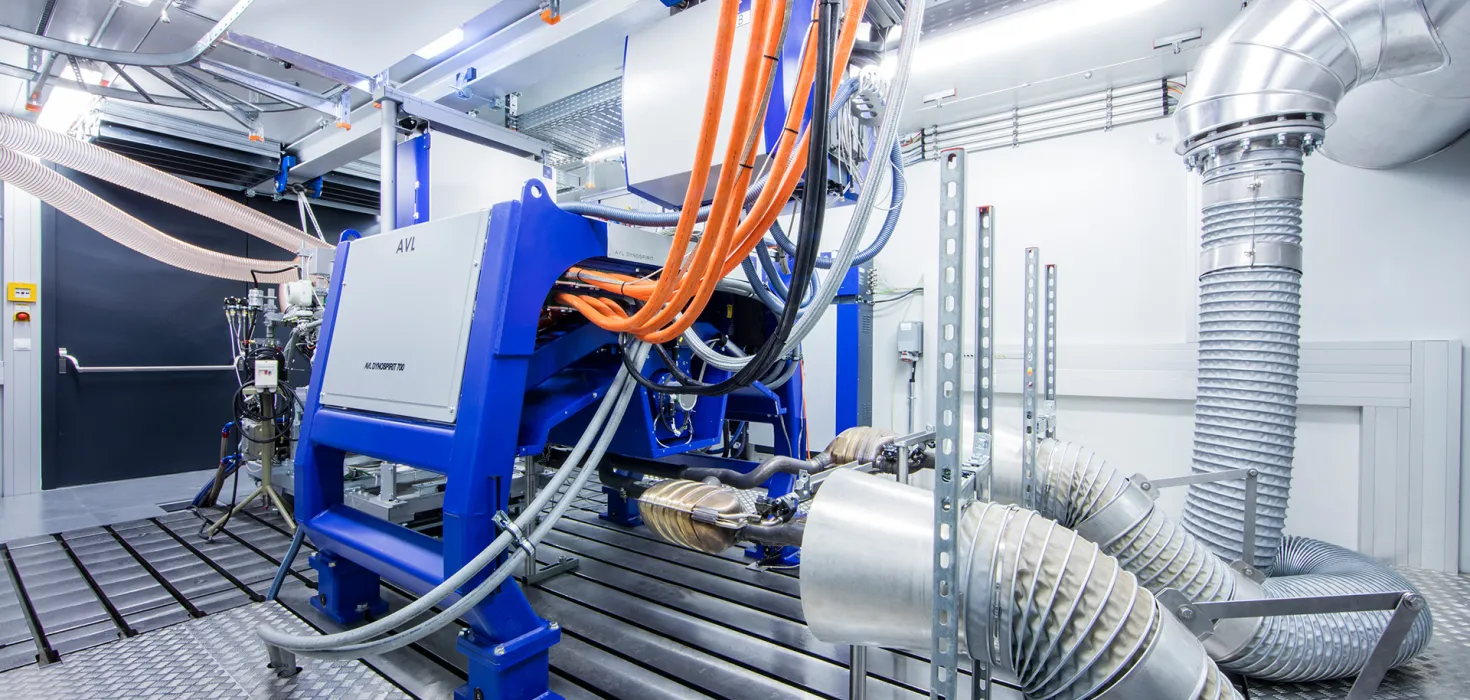

Developing e-motors with high power density and efficiency is crucial for modern automotive drives. It is equally important to ensure first-class driving characteristics in terms of comfort, economy, and sportiness. The AVL E-Motor TS™ Performance is designed to unlock the full potential of your e-motor and inverter. Its advanced mechanics and dynamometer design provide reliable testing at high speeds with precise control accuracy. Achieve fast, powerful, and reliable test results with our proven software toolchain.

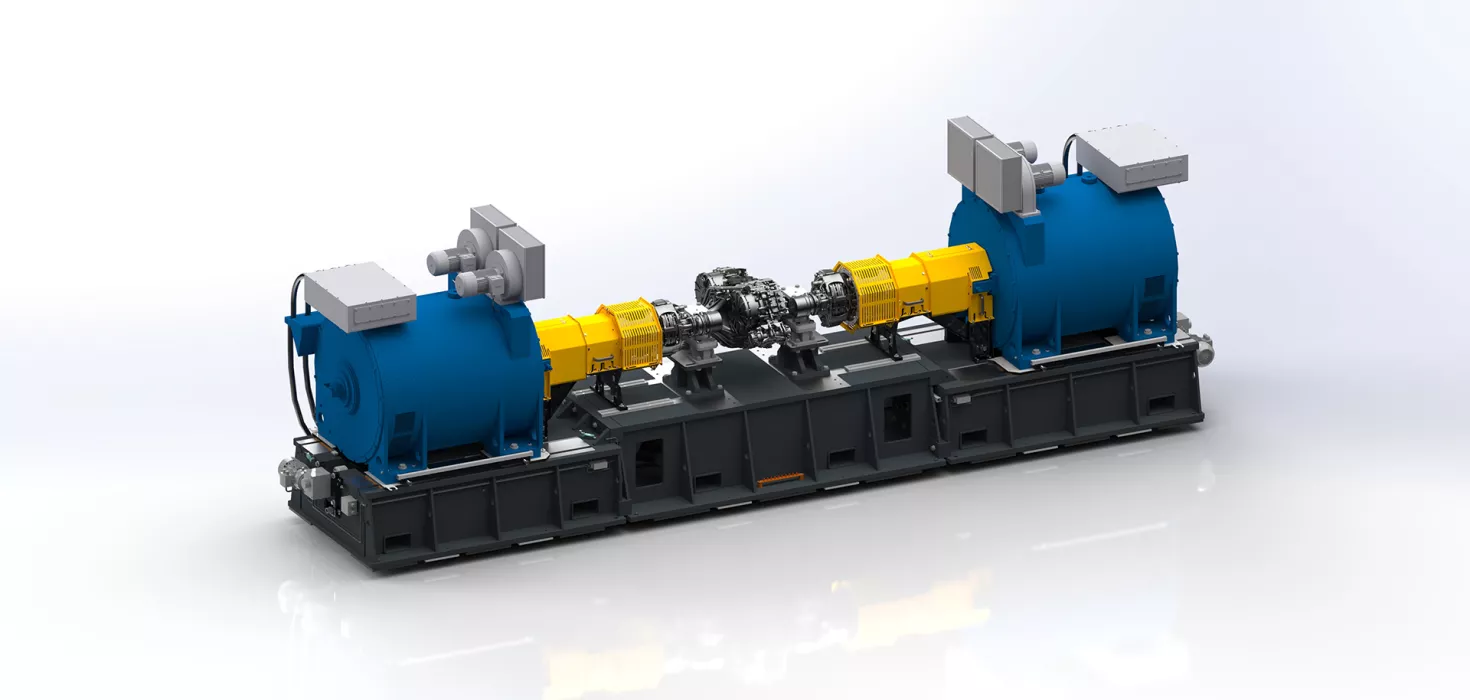

The AVL E-Axle TS™ Performance - Heavy Duty is a standardized test system designed for the development and validation of e-axles in commercial vehicles. Tailored for trucks and buses, it enables comprehensive life cycle testing under realistic vehicle-like conditions. The system supports precise performance and functional testing with capabilities of up to 20,000 rpm and 400 kW. It features a direct-drive dynamometer, flexible multi-channel cooling conditioning, and a climatic chamber for environmental simulations, ensuring the e-axles perform optimally in diverse operating conditions.

Our hybrid and engine test systems (TS) are highly flexible development environments. These test systems provide precise test and measurement systems with high reproducibility for testing internal combustion engines and their hybrid components. For hybrid engine development, the systems use battery emulators to act as electric power sources or sinks, ensuring highly realistic battery behavior emulation on the testbed. Dedicated fuel supply installations, including conditioning and consumption measurement, support multi-fuel testbed operation.

AVL offers comprehensive software solutions to optimize your rail testing performance. Our holistic approach combines lab efficiency through automation and test optimization via virtualization for faster results.

The advanced data analytics solution using AI extracts valuable insights from various sources. Additionally, our solutions are designed to seamlessly integrate with your existing systems, ensuring a smooth transition.

This will help you get your products to market faster while ensuring high-quality performance. Learn more about AVL’s approach and explore our software solutions to optimize your rail testing process now.

A battery test system is a testbed that includes at least one temperature chamber suitable for testing lithium-ion batteries, a cell or pack cycler in the appropriate current and voltage range, and an automation system. The size of the cell or pack determines which of various chambers with special safety equipment is required. In addition to the chamber, the cell or pack cycler and the required current and voltage ranges must be aligned with the respective batteries. Performance and durability testing can be carried out to understand battery and overall system behaviour.

At AVL, we specialize in the development and testing of fuel cells and electrolyzers - from single cells to complete systems. We combine individual measurement technology products into a test bed system and support you with mature methodology and industrialized test solutions so that you can concentrate on challenging development tasks. Thanks to the breadth and depth of our product range, we serve applications in railway and trains.

Electrolysis technology is now at a high level of maturity for alkaline or PEM (Polymer Electrolyte Membrane) and is thus ready for industrialzation. But also new technologies like AEM (Anion Exchange Membrane) or SOEC (Solid Oxide Electrolyzer Cell) are in development. To satisfy the green hydrogen demand, the industry requires validated and robust solutions. AVL is the innovation partner supporting every step in the industrialization from the first concept to in-field services with methodologies, know-how and tools.

Railway Technology Testing – Brochure

Innovation on Track.

Battery Testing for Rolling Stock – Solution Sheet

Boost your battery test process.

Traction Motor Testing for Rolling Stock – Solution Sheet

Optimum view of speed and torque.

Inverter Testing for Rolling Stock – Solution Sheet

Make the difference in power electronics testing.

AVL SPECTRA™ Universal Inverter – Solution Sheet

Versatile testing device for future-proof e-motor and inverter development.

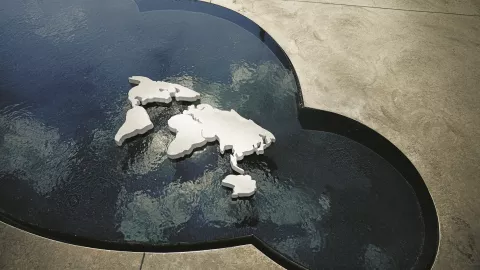

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience.

> 5,000

employees worldwide for testing solutions.

> 30

countries covered by the global network.

> 7,000

testbeds installed worldwide.

> 80

turnkey projects realized.