Download: AVL White Paper – Reducing GDI Engine Soot Emission by Minimizing Nozzle Tip Wetting

When fuel is burned in an internal combustion engine (ICE), pollutants harmful for human health and environment are released . The current public discussion focuses on nitrogen oxides emitted by Diesel engines. Another hot topic for OEMs is to find ways to reduce particulate matters produced by gasoline direct injection (GDI) engines.

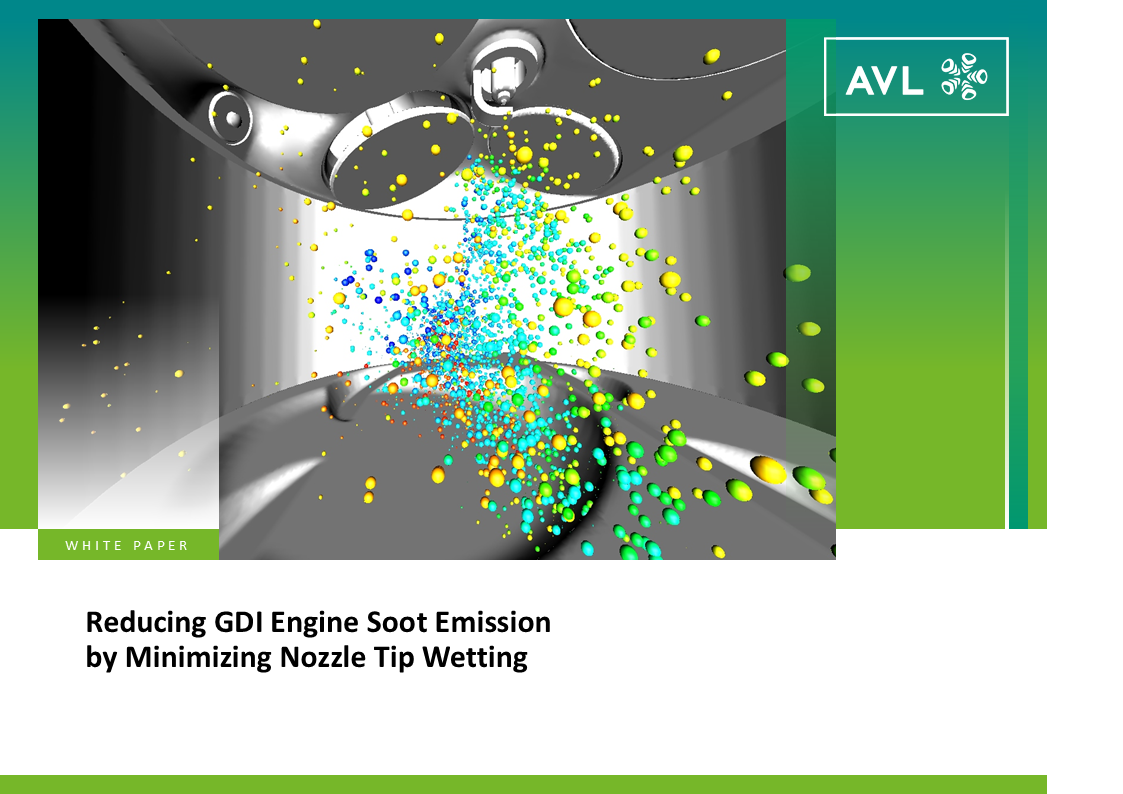

A large portion of the particles generated during a GDI engine’s working cycle comes from “sooting diffusion flames”, which appear at the tip of the injection nozzle. The target of today’s development is to reduce tip wetting as its cause. Potential measures focus on the design of the injection nozzle and the combustion chamber. Additional influencing factors are engine operation and fuel composition.

With the help of simulation, development engineers can easily analyze given designs and conditions regarding wall wetting and the occurrence of diffusion flames. As a result, various possibilities to reduce tip wetting and to lower engine out raw emissions open up to them.