E-motors for vehicles have special requirements. Weight and power density in particular are subject to a constant optimization process. Noise emission (NVH: noise, vibration, harshness) also plays an important role in terms of mechanics and electromagnetics. In addition, the issue of sustainability and availability of critical materials is becoming increasingly important.

Performance and Power Density

The industry needs ever more powerful e-motors, which should also be ever smaller and lighter. The focus is on an optimal ratio between continuous and peak performance. To avoid motor overheating, it must be cooled as efficiently as possible. A good thermal design removes heat at the point of its generation inside the motor, not outside via jacket cooling, which is common today. This in turn has a positive effect on the service life. In addition, it avoids the building of motors that are heavier and larger than necessary.

Costs

By optimally aligning the development, production, and performance of the e-motor, significant cost savings can be achieved compared to conventional e-motor developments. The challenge is to exploit this potential.

Efficacy and Efficiency

The e-motor and the overall system must be matched to each other mechanically, thermally, electrically and with regard to optimized control strategies. Every improvement in efficiency brings more range or saves costs in other areas, such as the battery.

Sustainability

The safe and affordable availability of raw materials, such as rare-earth elements required for permanent magnets, is becoming an increasing challenge. In the future, e-motors will have to be optimized regarding reusability and recycling. Magnet-free alternatives without loss of motor performance are also necessary.

Our development covers all aspects of e-motor development. We offer a complete simulation tool chain for electromagnetic design as well as for mechanical and thermal design. This enables you to perfect your e-motor, in particular with regard to NVH.

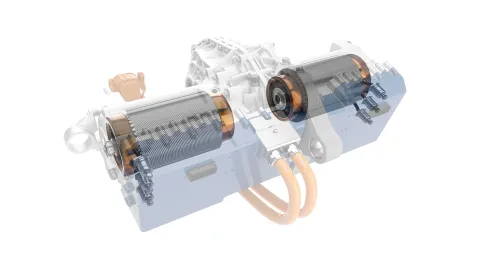

No matter which motor technology you want to push, we have high-quality references for permanent magnet synchronous motors as well as for asynchronous motors. We cover axial and radial flow machines. Our in-house research and development department is also working intensively on alternatives to these technologies.

When it comes to cooling, we offer every option – with particular expertise in the field of direct oil cooling.

Our many years of engineering expertise, paired with comprehensive methods and simulation solutions, enable us to tailor our e-motors precisely to your applications or to optimize existing solutions. Be it in the field of electric traction or for auxiliary units such as electric power steering or e-compressors.

Get There Faster

Using simulation, we can quickly calculate a large number of different design variants and optimize them with regard to specific key performance indicators (KPI). This not only saves you time, it also saves expensive serial design iterations.

Multi-Domain Optimization

Our simulation tool chain enables us to identify conflicting goals between performance, efficiency, costs and acoustics early on, and, for example, to improve the noise characteristics of your e-motor through optimized control concepts or mechanical design.

Design Validation Plan (DVP)

Our validation plan includes a detailed system analysis. Based on this, an error analysis will be generated including statistical planning of experiments (Design of Experiments – DoE). This provides more accurate results and reduces test runs.

Co-Optimization

Our development expertise covers more than just e-motors, it also covers inverters, transmissions, e-axles, and integration into the vehicle. We understand the interactions and can coordinate software and hardware perfectly, which results in optimized components in terms of costs, performance and efficiency.

Optimized Operating Strategies for Motor and Inverter

We use DoEs, coupled simulation and NVH analyses to optimize your control strategies – flexibly depending on driving cycle and scenario.

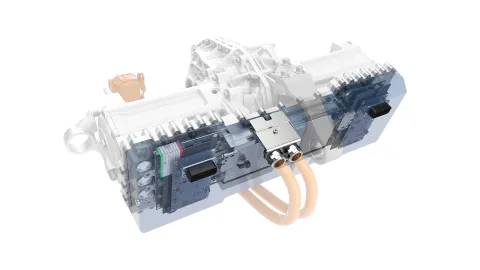

Innovative Cooling Technology

Our direct oil cooling system efficiently dissipates heat. This gives you an optimal ratio of continuous to peak power. You avoid oversizing the motor, which saves costs, weight, and installation space.

Installation-Space-Optimized Integration

We offer innovative e-machine architectures such as the axial flux motor. Thanks to its disk-like structure, you get motors with very high torque and compact dimensions, which can be better integrated into your vehicle concept.

Sustainable Motor Technology

Doubling the rpm with our high-speed e-motor enables us to minimize the use of magnets, and reduces the weight of the active components by up to 60 %.

Smaller Motor, Greater Power Density

Doubling the rpm also allows us to significantly reduce the size of your motor, thereby increasing the power density.

Complete Design and Layout

We provide you with the complete layout for your e-motor – including electromagnetic, mechanical and thermal design.

Prototypes

We deliver prototypes in small quantities. We also offer the option of helping you find a suitable partner who can produce larger quantities.

Tests and Validation

We not only use our test systems and processes for in-house developments, we also make them available for your own products. This allows you to make the best possible use of optimized test and validation procedures, and to consult our experts at any time.

Integration

With our in-depth understanding of the overall system, we provide support for the optimal integration of the components into your propulsion system or vehicle.

We have been using 800-Volt, direct-oil-cooled e-motors for more than ten years and have also expanded our expertise into high-speed machines with up to 30 krpm for very high power density as well as better sustainability and performance in a wide variety of projects. Our innovations show that we have our sights set firmly on the future. This enables us to consolidate our pioneering role.

– Dr. Thomas Frey, Head of Segment E-Mobility & E-Drive System, AVL Software and Functions GmbH

Related Topics

We are constantly working on new solutions. The following might be interesting for you: