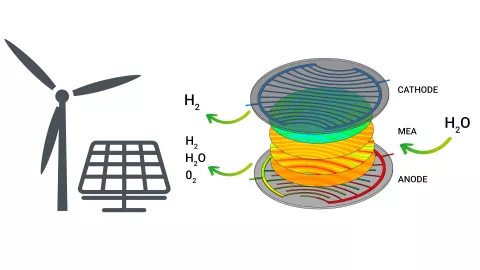

Hydrogen is a promising option for storing surplus energy from renewable sources, such as photovoltaics and wind. Various electrolysis technologies are suitable for the production of green hydrogen. Due to the achievable efficiencies and their appealing dynamic behavior, PEM electrolysers are often used today.

The performance, efficiency and service life of PEM electrolysers are largely determined by the transport and conversion processes that take place in the individual cells of the stacks. Under real geometry and operating conditions, these are largely inaccessible by experimental analysis and thus a detailed evaluation and correlation with global operating parameters is extremely difficult, if not even impossible.

In our live webinar, we will show you how you can use 3D multiphysics simulation to gain detailed insights into fluid flow as well as thermal and electrochemical processes in PEM electrolysers. These findings can then be used to optimize the anode and cathode flow-field designs, to select material properties of the membrane-electrode-assembly in a targeted manner, and to derive boundary conditions for system considerations.

Key topics and takeaways:

• Possibilities of 3D multiphysics simulation to visualize cell/stack internal transport and material conversion processes

• Interpretation of spatially resolved concentration, temperature and current density distributions as a function of global operating parameters

• Simulation-based quantification of the effect of LGDL and CCM material parameters on electrolysis efficiency

• Analysis and optimisation of operating parameters