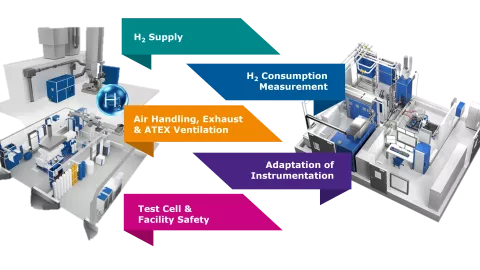

AVL's fuel cell production test solutions cover a wide range of applications, through the modular solution approach we support you with your individual needs in the following areas.

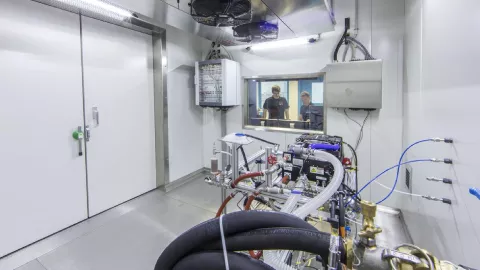

Cold tests to confirm operational safety and achieve H2 release, such as: Leakage tests, stack short circuit tests, potential equalization tests, high-voltage isolation tests, dielectrical strength tests, integration of fuel cell control unit and resulting tasks and opportunities.

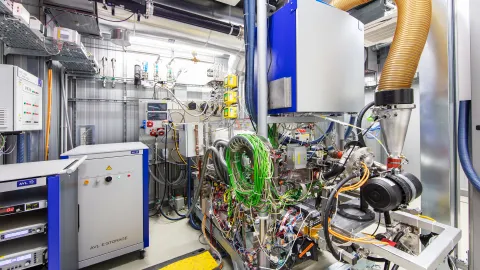

Hot tests to activate the PEM fuel cell and confirm its begin of life performance as well as aspects of further quality assurance, conformity of production and performance testing.

| Property | Unit |

|

Power level |

Up to 400 kW |

| Unit-under-test (UUT) | PEMFC stack and system, bipolar-plate, cell, balance-of-plant-components or SOFC testing solutions |

| Application | On-road and off-road mobility, aviation, shipping and industrial |

| UUT handling and integration | From manual to fully automated |

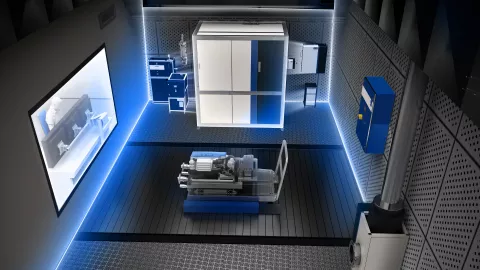

Customized design

We offer you full flexibility in the realization of a customer-specific test solution layout in the production environment by means of our modular and flexible product approach.

Industrialized standard products

We guarantee you full planning security due to industrialized standard products and sustainable spare parts availability combined with a strong, established and global network in the area of customer service.

Automation system

We secure test bench and data management via our real-time automation system "Puma 2 Production for Fuel Cell", the global industry standard for test bench automation with 45 years of history, local and remote, for individual test benches and complete test fields.

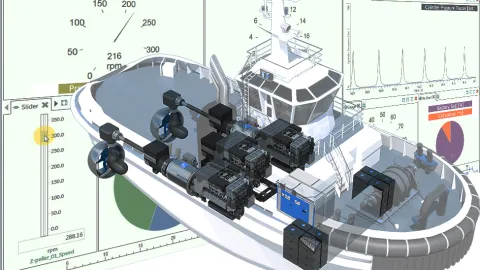

Data analysis & reporting

We support in data analysis and reporting through configurable and automated evaluation routines directly at the point of test, and other quality monitoring tools such as machine learning.

"I am surprised every day by the broad and deep expertise AVL has in a wide variety of areas, from simulation and software to virtual and augmented reality to the realization of complete turnkey solutions. It allows me to collaborate with a variety of areas and teams to further optimize our production test solutions for fuel cells."

– Michael Standke, Application Engineer Fuel Cell Testing, AVL