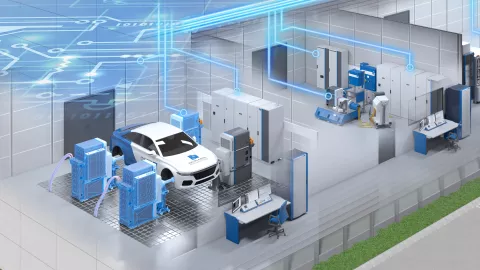

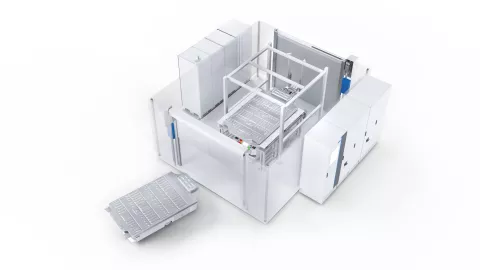

Increasing production volumes and testing rates of up to 100% in the e-mobility sector mean that testing equipment must meet more challenging requirements. This concerns all components of the electrified propulsion system, which are manufactured in an increasingly automated production environment. To make this happen, we seamlessly integrate production testing into production lines, thereby optimizing testing capacity. In addition, connecting highly effective processes and equipment results in a solution tailored to your individual requirements.

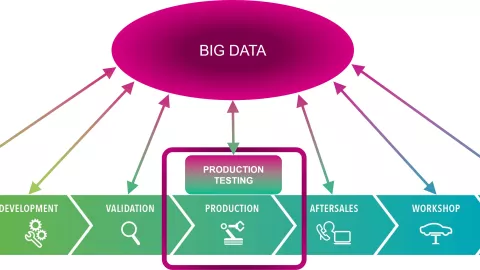

At AVL, we see production as the central part of a product’s lifecycle. Production testing is a key data generator in a production line, making it essential for securing and optimizing both production process and product quality. Generated data is also a powerful tool for other phases in the product’s lifecycle – from concept to in-use. To process obtained data usefully, our in-house software solution PUMA 2™ is the perfect companion for our testing equipment.

At AVL, we see our production testing solutions as an important factor for both an effective production process and high product quality – a major pillar our customers can rely on.”

– Robert Nemeth, Department Manager, AVL List GmbH