The omnipresent desire to make mobility more sustainable as quickly as possible continues to drive the industry's evolution. In addition to pursuing different drive concepts, OEMs need to take a closer look at their design cycles. E-mobility in particular is leading to new players entering the market and launching vehicles in less than 18 months. Such times cannot be achieved with a traditional development process.

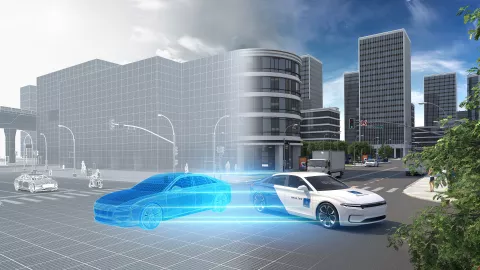

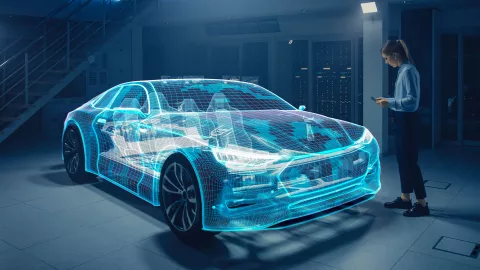

Used throughout the entire process, the virtual twin supports you in analysis, simulation, optimization, and decision-making. It is the digital image of a single cell, a component, the entire system, the vehicle. But it is much more. Because it has the ability to interact with all other objects in the system, with the software and control functions, and above all with its environment. With him, you bring your virtual development to life.

Simulation-based development was originally built on complex models and a large number of steps to make the models ready for use. With the advancement of technologies and the shortening of development cycles, a change can now be observed.

Currently, it can be observed that virtual development is becoming the standard in the development process. The key factors are the high quality of the Virtual Twin and the increasing ease of use of the software. These factors are leading more and more engineers to recognize the potential of replace the time-consuming and costly testing of physical prototypes in development.

Environmental awareness in society is on the rise. Consumers and politicians are demanding: rapid innovative concepts for CO₂-neutral mobility. The many different requirements such as range, performance, comfort, etc. for the propulsion systems make a single-system solution impossible.

Versatility as the Key to Success

The development of a wide range of propulsion systems can no longer be managed using classic methods. At the same time, the change in mobility also presents personal challenges. The knowledge and skills accumulated over decades must now be transferred to modern drives. The pressure to find the right answers is greater than ever before.

Master Complexity

The number of systems in a vehicle is increasing, as is the interdependence of the individual components. So, it is not surprising that their development is also becoming more complex.

Engineers therefore choose a systemic development approach and no longer consider the individual components separately. This requires not only interdisciplinary knowledge, but also a tool landscape that enables them to work across disciplines.

- Speed up your development by implementing simple and repeatable processes: from initial concept through system design to component construction and testing.

- Create accurate Virtual Twins, and thus reduce the number of prototypes required. Virtual Twins do not need expensive raw materials and are comparatively fast to create.

- View the entire vehicle level without a physical prototype using multiphysical and multidisciplinary simulation. Perform your tests virtually in realistic environments.

- Avoid warranty costs and image loss due to unreliability. Test your virtual twin extensively in the shortest possible time.

The Virtual Twin enables us to make the impossible possible: It makes it possible to design a product, system or software completely digitally while predictively evaluating its performance from a multi-physics perspective. At the same time, it allows us to virtually explore the entire design space.

- Roland Wanker, Vice President Advanced Simulation Technologies, AVL

The diversity of requirements placed on modern vehicles makes it impossible for OEMs to rely on just one technology. However, this must not be at the expense of development time and quality. Their large portfolio and diverse systems require a tool landscape that allows them to be as flexible as possible.

This is exactly what we have developed our Simulation Suites for. Each suite is a comprehensive simulation solution that you can use throughout the entire development process - from initial concept creation to the vehicle.

AVL eSUITE™

The eSUITE is the flexible, fully integrated simulation solution for electrified powertrains and systems.

From Component to System to Vehicle

The eSUITE covers all areas - from the overall system to the individual components of e-axle, battery packs or fuel cells.

For the independent creation of precise virtual twins, it offers you:

- Guided workflows

- Intuitive generators and wizards

- A library of validated models

AVL iceSUITE™

The iceSUITE bundles simulation solutions for the efficient and state-of-the-art development of combustion engines.

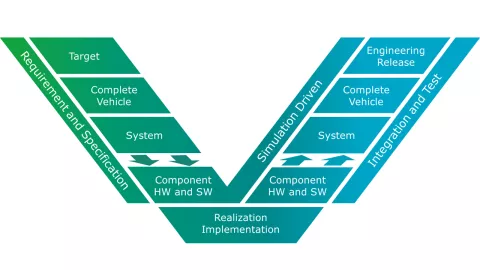

Applicable Throughout the V-Process

In addition to optimizing engines, you can also virtualize testing under a wide variety of conditions.

The modeling capabilities are scalable and support you at any level:

- In the input of parameters

- In the simple exchange of results

- By consistent reports through the entire development process

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

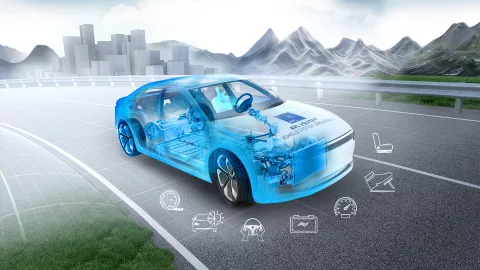

AVL vSUITE™

The vSUITE is the newest member of the AVL Software Suites.

Designed for a Holistic Approach in Vehicle

The comprehensive system simulation solution enables you to take a development approach that considers the interdependencies of vehicle properties.

It supports you in the development and optimization of functional vehicle properties. These includes:

- Energy management

- Fuel consumption

- Driving behavior

- Driving dynamics

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

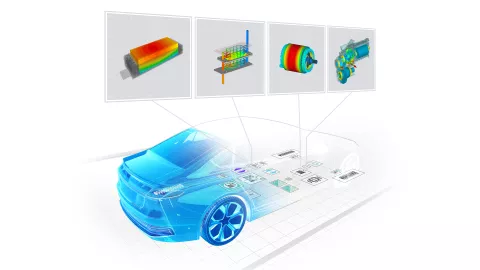

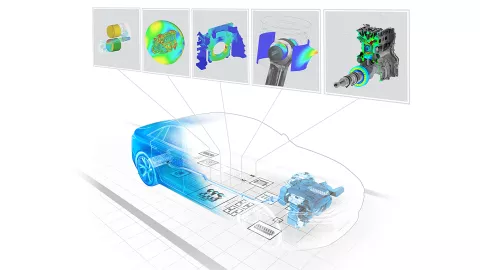

Simulations Tools from A to Z

Our simulation solutions are also powerful software tools that can be used stand-alone.

Consideration of the Smallest Particles up to the Entire Vehicle

Simulation is used throughout the entire development process. Thanks to Virtual Twins, you have the opportunity to view all areas in and around the vehicle accurately and from your desk.

We offer you simulation solution based on:

- Computational fluid dynamics

- Multi-body dynamics

- Multi-disciplinary vehicle systems

- Smoothed-particle hydrodynamics

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

Software Releases

Find out more about our latest software releases.

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

(H4) Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

The mobility revolution is in full swing. This is not just about developing new, more sustainable propulsion systems. Rather, the entire development process is in upheaval - with simulation taking the lead.

Right now, it's important to understand the challenge that each of us - OEMs and suppliers alike - face when it comes to pushing the boundaries of both our design process and our engineers. As the number of different systems grows, departments and team structures are changing. We understand that. At AVL, we go through these processes as well, because we are not just software developers. We are also engineers and therefore users. We implement our knowledge in intuitive workflows, generators, wizards, and evaluations in our software and projects.

We are your global partner in realizing the mobility of the future. A mobility characterized by its minimal impact on the environment. We offer you simulation solutions ranging from component to system analysis. As we are deeply integrated in the development process, our software solutions - tools and projects - enable you to master the challenges of virtualization.

75+

years of experience

in 26

countries worldwide

12,200

employees worldwide

68%

engineers and scientist