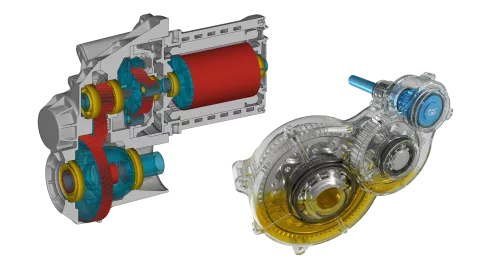

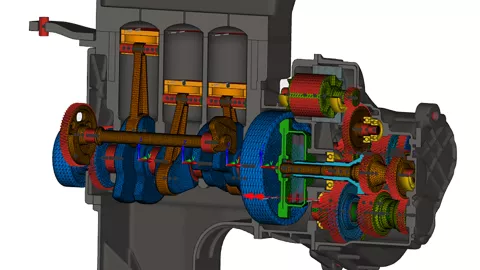

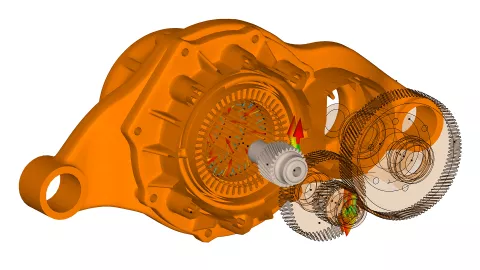

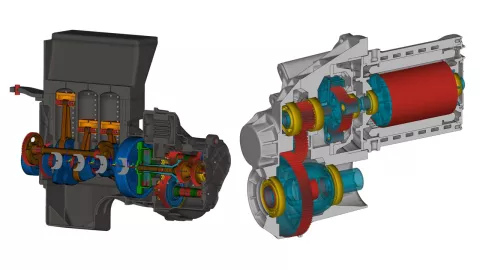

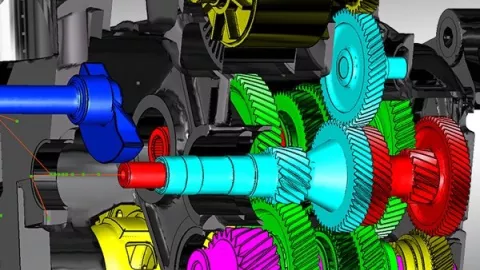

Starting with simple modeling of geometry, using rigid bodies and linking the components with plain or roller bearings, gear pairs as well as rotational coupling elements such as couplings or splined shafts, a simulation model can be quickly built.

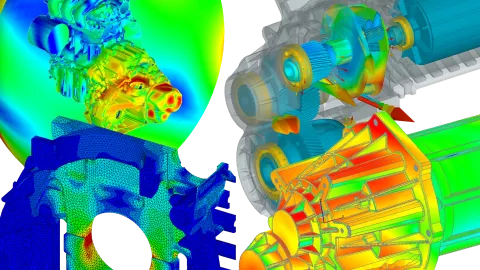

With the help of the integrated Component Modeler, sophisticated FE models can be seamlessly prepared and flexible components can be created. Fully integrated assemblies, e.g. for planetary gear sets or crank trains, offer an enormous simplification for the creation of complex calculation systems. The interaction of the components can be easily checked with the help of a kinematic calculation and animation. This is followed by the actual simulation. You can choose between fast analyses in the frequency domain or non-linear analyses in the time domain for detailed investigations.

As a user you automatically receive for evaluation: Campbell diagrams for series calculations and a standardized report as PowerPoint or PDF file.

AVL White Paper – AVL E-Motor Tool™ – Bridge the Gaps in E-Motor Development Workflow

Development processes that rely heavily on simulation have been honed over time for conventional powertrains, but they could also be applied to e-drive development. However, some gaps specifically related to the e-drive development, must be bridged to ensure a smooth development process. This whitepaper demonstrates how the innovative E-Motor Tool supports e-drive development.

The AVL E-Motor Tool™ - Easily Parameterize the E-Motor Emulator for Inverter Testing

E-Motor Emulator is used for the physical testing of the inverter removing the need for a physical e-motor. With AVL E-Motor Tool it is possible to effortlessly design a customized e-motor tailored specifically to your inverter testing needs. The precise set of parameters for this e-motor are provided to the E-motor Emulator in one click.

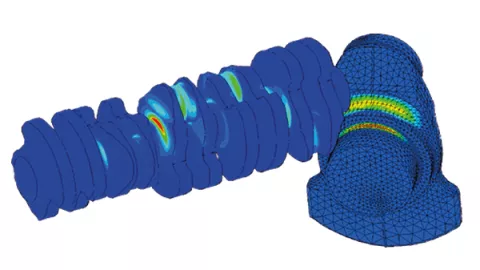

AVL Customer Case Study - EHD Bearing Simulations on WinGD 2 Stroke Engines

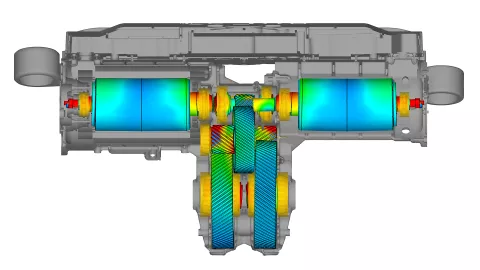

Increased demand to minimize cylinder distance for new twostroke, low-speed marine engine developments, including new engine structure concepts and design-to-cost approach, result in an increased need for EHD calculations of WinGD`s main bearings.

Find out how our multi-body dynamics simulation solution AVL EXCITE™ helped WinGD to successfully deal with this challenge.

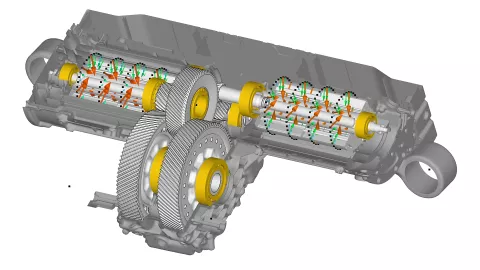

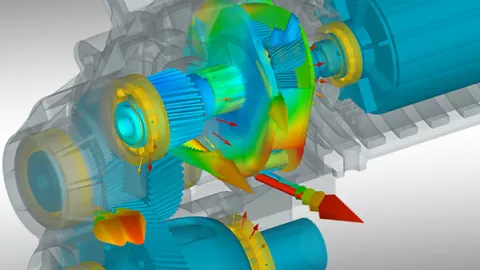

AVL White Paper – Predictive Transmission NVH Analysis for ICE Based and Electrified Powertrains

Download our white paper to discover how simulation can be applied to optimize key powertrain NVH attributes, extending classical IC engine NVH to modern powertrains including highly complex transmissions and electrified powertrains.

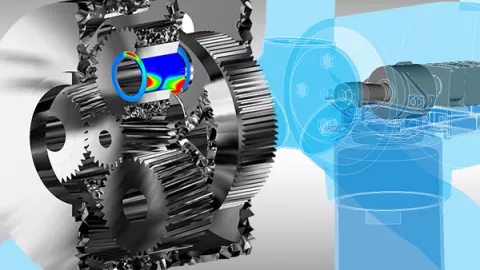

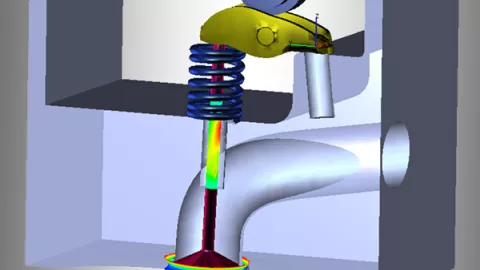

AVL Customer Case Study - NVH Simulation at Deutz

Legal constraints which impose ever stricter emission limits are forcing engine manufacturers to drastically reduce the sound emission of their products. In addition, increasing end customer expectations require a greater focus on the acoustic behaviour of an engine.

AVL Customer Case Study - System Simulation in BEV Development at EDAG

For battery electric vehicles (BEV), the high-voltage storage unit is the crucial component in terms of performance, efficiency and range. To optimize these attributes extensive investigations are required. Both in the overall vehicle context and under different, sometimes extreme boundary conditions.