Data gives one the confidence to clearly decide which concepts to follow. A solid data basis is especially important when mobility concepts are evaluated with regard to multiple factors at the same time.

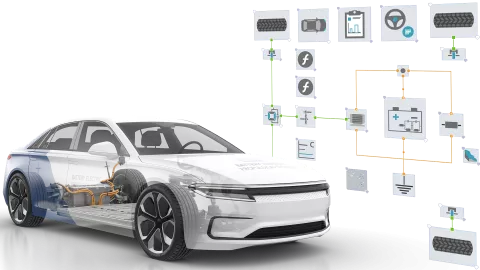

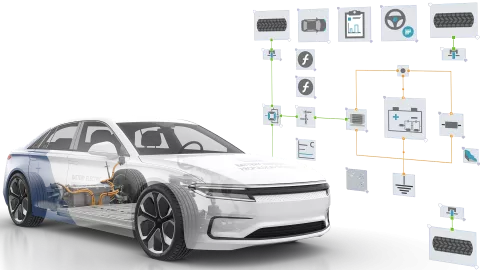

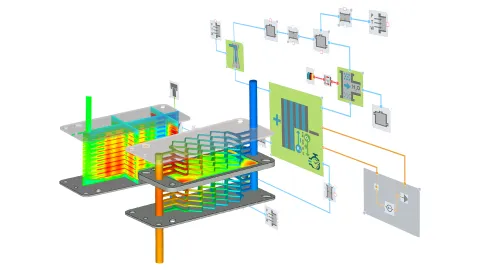

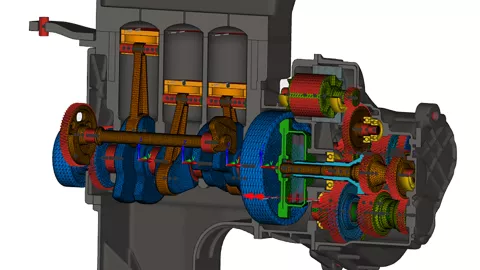

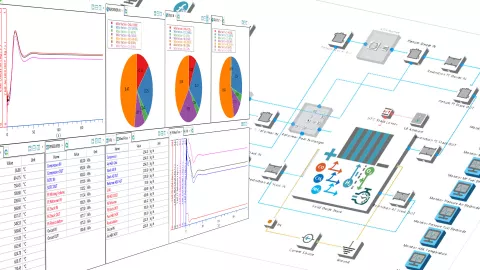

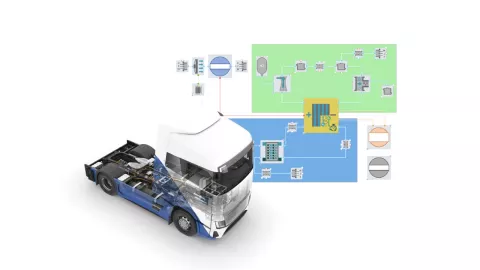

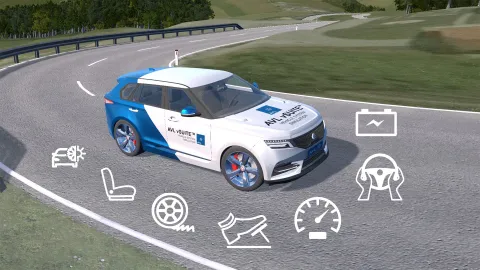

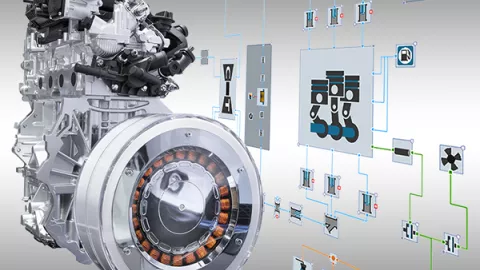

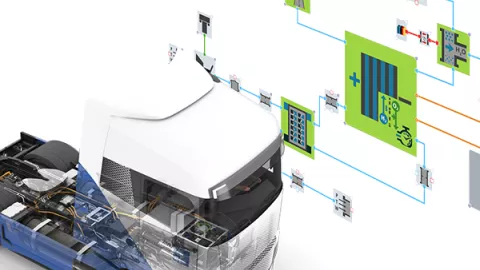

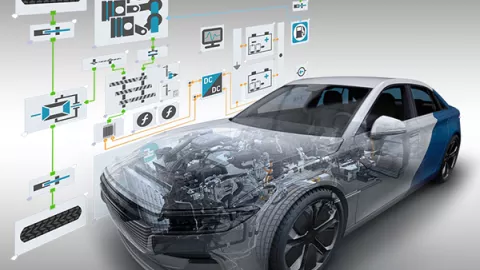

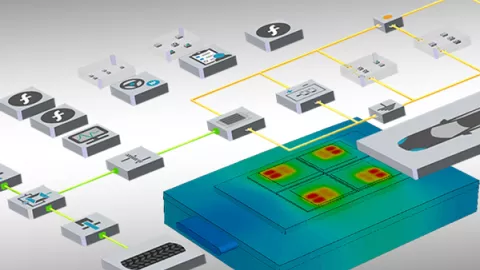

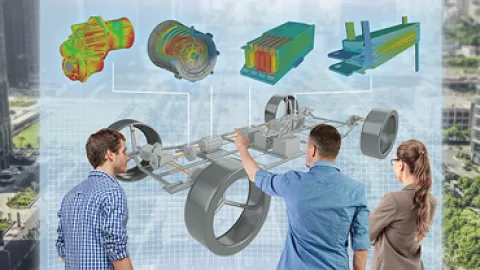

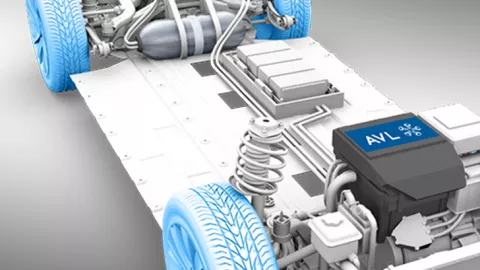

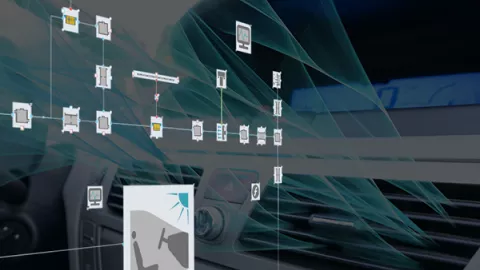

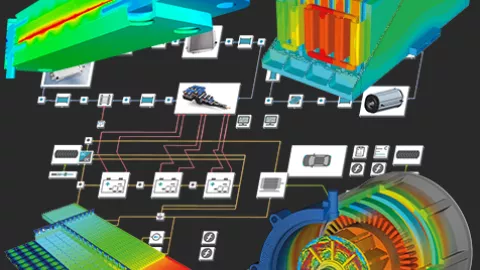

This is exactly what AVL CRUISE™ M stands for. With the different components of the software, electric, fuel cell, hybrid and combustion engine concepts can be analyzed. The software offers an extensive component library of physical models such as for battery packs, fuel cells, cooling systems as well as for e-motors and also allows the implementation of the associated control strategies. This enables the simulation of their effects on performance, energy efficiency and lifetime.

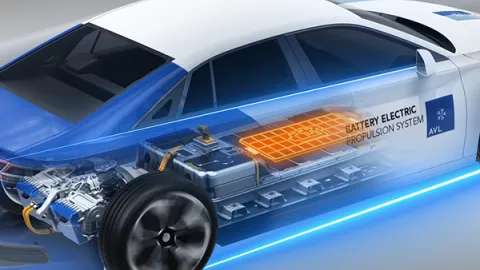

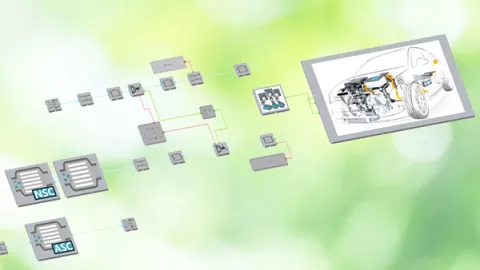

In order to achieve the set vehicle targets, a suitable system must be developed. Due to the large number of variants and combinations of vehicle components and their interaction, vehicle development is a complex optimization task. Concept studies help to avoid late and costly changes from the outset.

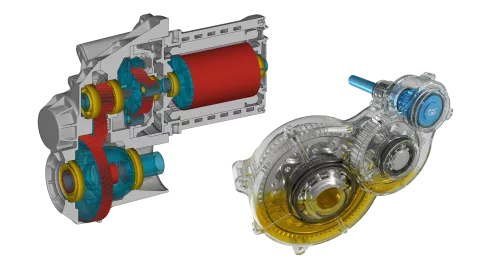

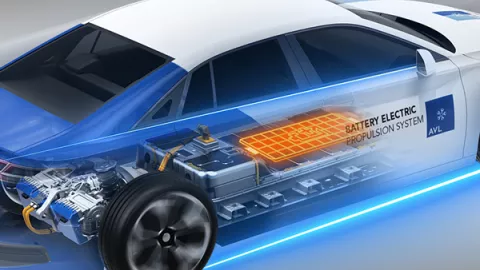

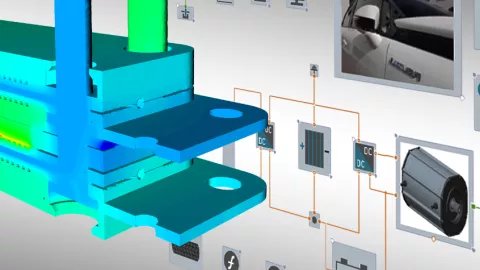

In the case of battery electric vehicles, for example, questions about the battery pack and cells as well as the type of thermal management have to be answered. In addition, requirements for the electric motors, their coordination with the transmission and the operating strategies must be clarified.

Model Parameterization

Easy-to-parameterize models with high prediction quality for performing concept studies

Scaling of the Model Depth

Studying the interrelationship between the different domains in the course of the development process

Real-Time Capable Models

Calibration of controls using virtual models in a Mil/HiL/SiL environment

Reliable and Fast Calculation Methods

As a starting point for detailed 3D simulations to evaluate requirements such as performance, size, etc. for individual components

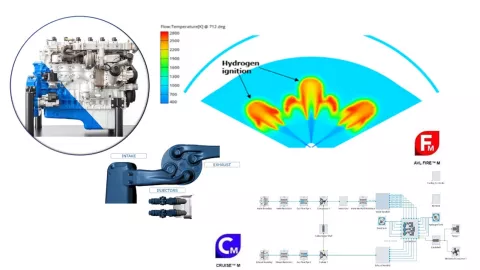

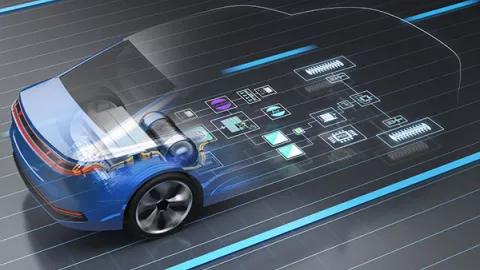

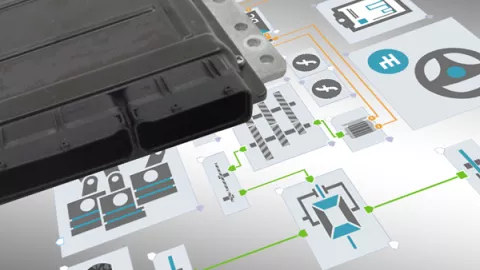

CRUISE M models all relevant physical areas that occur in a vehicle. These include electrical networks, thermoregulation systems including air-conditioning circuits, mechanical and thermodynamic systems, and a generic data and function network for control tasks. In these networks, the software models complex reaction chemistry for electrochemical processes, heterogeneous catalysis, or homogeneous gas reactions.

This allows you to design and optimize both subsystems and the overall system in a network in detail.

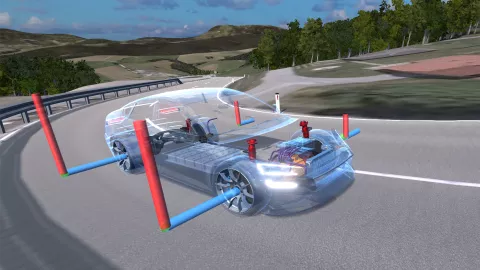

Real-Time Capability

The dialog between models and real components on the virtual testbed takes place in milliseconds. This is the range in which CRUISE M realistically predicts the behavior of the virtual components.

Cross-Process and Compatible

CRUISE M models support you in your entire engineering process. Standardized interfaces such as FMI allow models created in other modeling environments to be easily coupled and simulated as part of an overall CRUISE M model.

Time and Cost Savings

Simulation is a way to answer many questions right at the beginning of the development and thus to get on the right track early. In any case, CRUISE M can be easily integrated into your existing development environment.

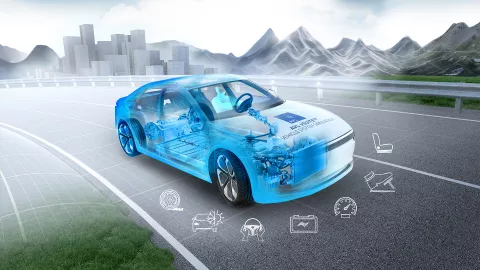

Validated Vehicle Models – Versatile Development Aids

The AVL database currently includes more than 300 validated models of vehicles with a range of drive concepts – from conventional internal combustion engines to hybrid concepts and battery-powered and fuel-cell-driven vehicles. For example, there are validated AVL models of the Porsche Taycan, the Toyota Mirai II, the Toyota Yaris Hybrid, the Hyundai IONIQ 5, the Tesla Models 3 and Y, and many more vehicles. The database is being updated continuously and specific models can be created on request at any time.

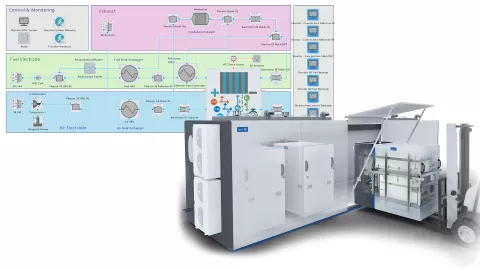

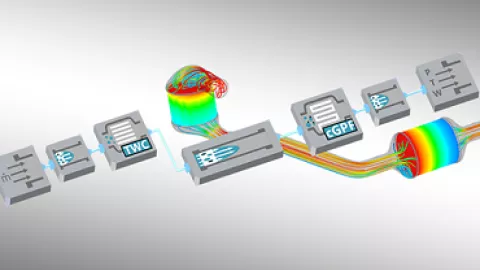

Electrochemical Model for PEM and SO Fuel Cell

The software's proven real-time capability makes it ideal for developing operating strategies on virtual testbeds. This enables the analysis of operating conditions such as high-altitude operation or freeze-start strategies, which otherwise require complex tests on climatic testbeds. In addition, cell and stack geometries can be calculated at high resolution in 3-D with high performance.

The real-time modeling of thermodynamic systems in CRUISE M is ideally suited for the development and optimization of Balance of Plant (BoP) components for fuel cell media supply. For low-temperature proton exchange membrane (PEM) systems, tailored models for water balance and thermoregulation cycles are used. System models of solid oxide (SO) fuel cells include a number of catalysts for conditioning and post-conditioning of the media streams.

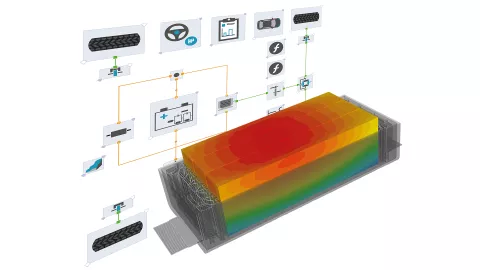

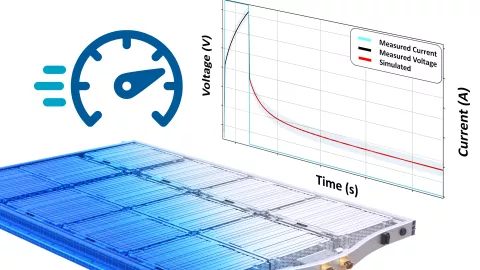

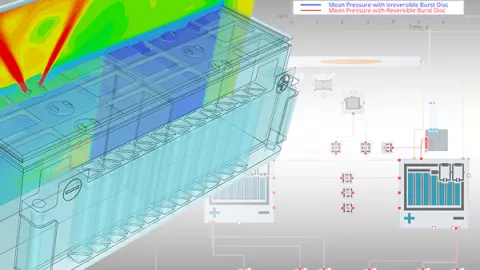

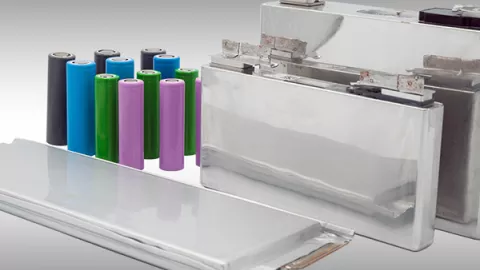

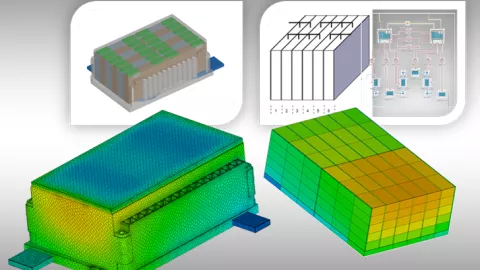

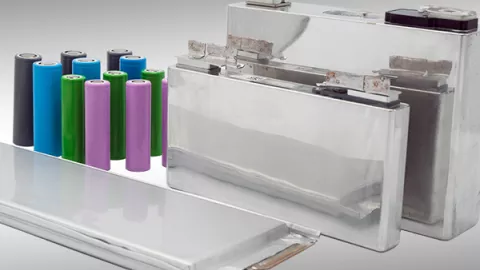

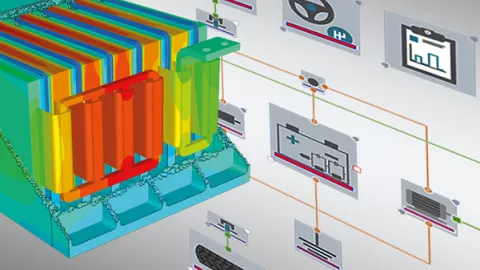

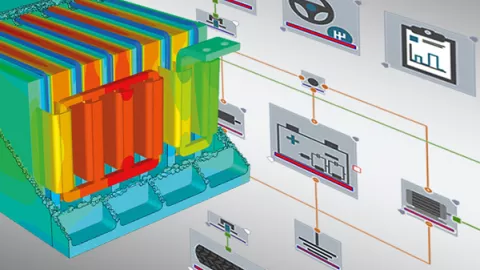

Multiscale and Multidomain Model for Battery Modules

The electrochemical behavior of battery cells is strongly influenced by temperature. Temperature in turn depends on both electrochemistry and thermal management of the battery module. CRUISE M provides you with a customized component that allows you to model these causal chains across multiple scales and domains effortlessly.

The module components for pouch, prismatic and cylindrical battery cells capture the electrical, thermal and mechanical coupling of the individual battery cells. This enables the analysis of thermal management concepts and fast charging strategies. You can choose between cell models from the CRUISE M library or your own models.

If you want to investigate new battery types virtually, CRUISE M offers extensive configuration options from electrode materials down to intercalation and aging chemistry. Importantly, your IP remains protected even when sharing models with partners.

Parameterization Wizards

To relieve you from the manual setting of parameters, CRUISE M has a number of wizards.

There are wizards available for parameterizing batteries, fuel cells, turbochargers, cylinders, pressure losses and much more. The wizards guide you through all input steps and you get a parameterized component quickly and easily.

Model Generators

Do you have only rough performance data of your system? CRUISE M creates a detailed, complete model from it, too.

Model generators are available for battery packs, fuel cell stacks, combustion engines, vehicle drives and much more. The model input parameters of all components are set automatically.

Our full-vehicle thermal models, developed in AVL CRUISE™ M, allow us to quickly evaluate design concepts and projected performance of thermal management components in next-generation BEVs. Using system simulation in CRUISE M, we can define realistic operating conditions early in the development process and efficiently manage the evolution of specifications through the development stages.

– Dr. Davide Monsorno, Advenced Development Engineer, Röchling Automotive S.r.l.

We use AVL CRUISE™M because of its extensive library and flexible interfaces. All components show a very good level of accuracy perfectly suitable for the integration of our detailed in-house stack model into the CRUISE M system model, we can then couple this with the CRUISE M library components in any combination set by our requirements.

– Dr. Sönke Gößling, Group Manager Simulation and Control Fuel Cell Systems, ZBT GmbH

We use AVL CRUISE™ M to analyze and develop engine combustion processes for the maritime energy transition as part of our TEME2030+ research project. This enables us to evaluate technical concepts at an early stage and to pursue exactly the right path.

– Dr.-Ing. Martin Theile, CEO, FVTR GmbH

With AVL CRUISE™ M, we can simulate a hardware-in-the-loop environment for a future fuel cell testbed. Integrating the fuel cell model in CRUISE M also allows us to precisely design the testbed components based on the fuel cell, before we even start building the testbed.

– Jonas Endres, Research Associate, Institute for Combustion Engines and Vehicle Drives (VKM), TU Darmstadt

With AVL CRUISE™ M, you can quickly analyze the complex relationships and many factors involved in hydrogen rapid refueling. This tool also saves time and money during the development of this new technology, where there are no existing benchmarks. It allows you to optimize and coordinate various components and refueling options in the minimal time."

– Bernhard Miksovsky, Development Engineer, Liebherr-Werk Bischofshofen GmbH

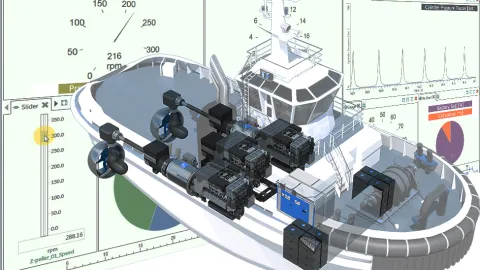

Modelling and Simulation of a Fully Electric Hybrid Propulsion System for Passenger Ships Using AVL CRUISE™ M Software

The maritime industry's pursuit of sustainability drives the exploration of alternative fuels, with hydrogen emerging as a promising solution. This paper describes a comprehensive study on a fully electric hybrid propulsion system for passenger ships, utilizing hydrogen as the primary power source.

AVL White Paper - Efficient Battery Thermal Management in BEVs

In this paper we present a numerical approach using AVL CRUISE™ M to design a snake shaped cooling channel for cylindrical cells.

AVL White Paper – Virtual Integration of xEV HVAC Systems in the Vehicle Thermal Network

In order to increase the driving range of Electric Vehicles it is essential to address the issues of thermal management and HVAC. The easiest and most efficient way to do this is by using system simulation complementary to real-life testing and experimentation. Download this White Paper to discover how many tasks can be frontloaded to a much earlier stage in the vehicle development process with the help of simulation.

AVL White Paper – VTMS Layouting of xEVs using System Simulation

Components of electrified powertrains are very sensitive regarding their operating temperature. Therefore, their proper temperature prediction during transient vehicle operation is essential. Download this whitepaper to see how our simulation solution combines thermal with mechanical and electrical systems in a consistent environment.

AVL White Paper – Model-Based Control Function Development for Gas Engines

Model-based development enables frontloading of control-system development. Download this White Paper to learn more about our approach on model-based control function development for gas engines.

AVL White Paper – The Role of System Simulation for Battery Electric Vehicle Development

OEMs that succeed in bringing electric vehicles to market fast are in a strong position to dominate the industry. System simulation is the key to accelerating their development. Download our white paper and find out how it supports the analysis of the overall powertrain along the whole process and today.

AVL White Paper – Virtual Fuel Cell Performance and Lifetime Optimization - From Component to Vehicle Level

Download our white paper to find out how AVL eSUITE™ helps OEMs and suppliers get the best performance and longest lifespan from this clean power source.

AVL Customer Case Study – Simulation of Fuel Cell Systems at ZBT

In the case of fuel cell electric vehicles (FCEVs) the configuration of the fuel cell system and the traction battery, interaction of the two components in terms of resulting performance, efficiency, and range are particularly crucial.

AVL Customer Case Study - System Simulation in BEV Development at EDAG

For battery electric vehicles (BEV), the high-voltage storage unit is the crucial component in terms of performance, efficiency and range. To optimize these attributes extensive investigations are required. Both in the overall vehicle context and under different, sometimes extreme boundary conditions.

The demands placed on modern vehicles go far beyond pure transportation. In addition to performance and energy consumption, the decisive factors are above all subjective attributes that make up the driving experience and ensure comfort. With electrification, vehicles are becoming increasingly complex. To find the ideal vehicle concept, a large...

Range and performance are crucial to the success of electrified vehicles (EVs). For vehicle manufacturers, this means that energy-intensive systems such as heating, ventilation, and air conditioning (HVAC), as well as Vehicle Thermal Management Systems (VTMS) and the E/E architecture have a special place in development.

Range, performance, costs and safety are the parameters by which electrified vehicles are measured. As a central object, the battery has great potential here. The right design and a smart operating strategy are the key to optimal use. However, once it has reached the end of its lifetime in the vehicle, using it as a large-scale storage unit offers...

Fuel cells and electrolyzers are excellent solutions for efficiently achieving a CO2-neutral future. Especially since their application is multifaceted. It ranges from vehicles of all sizes to energy generation and storage to the starting point for synthetic fuels (e-fuels). Develop and optimize targeted fuel cell systems by using our simulation.

Electrified vehicles (EVs) are measured by their performance, range and cost. In addition, a compact powertrain design is desired, which has implications for thermal management.

The nearly silent operation of e-motors makes the vehicles quieter, but results in various noises and vibrations no longer being masked by the engine.

AVL is a leader in the use of simulation in vehicle development. Our simulation solution for combustion engines is used by most engine manufacturers worldwide.

With simulation, we achieve three things in powertrain development: First, we ensure durability for all components - from the crankshaft to the connecting rod and plain bearings to the entire...

Solid oxide fuel cells are a promising technology for power generation within the context of renewable energy systems. This is mainly due to their high efficiency, fuel flexibility and environmental compatibility.

Battery development requires accurate cell parameters, especially voltage and temperature responses. Equivalent circuit models (ECM) are common as they can be used in battery management systems. An innovative approach shortens the parameter identification process from weeks to hours through virtualization and precise cell models.

The drastic shifts in the transportation business brought about by recent and also upcoming emission and greenhouse gas laws as well as the broader shift towards a decarbonized society are giving a tremendous push to the development of hydrogen combustion engines.

Aiming at a drastic CO₂ reduction in industry and mobility, the world is currently facing the challenge of producing green hydrogen at affordable prices and in sufficient quantities.

The advantages of the rotary piston engine make it the ideal source of propulsion not only, but especially, for small, unmanned aircraft. A market that is growing rapidly around the world as ideas are realized to use them for civilian purposes beyond military applications.

Immerse yourself in the world of Solid Oxide Fuel Cell (SOFC) physical modeling in our exclusive webinar and learn how to use the impressive capabilities of AVL CRUISE™ M in combination with ESTECO's intelligent optimization tool modeFRONTIER.

Learn more about the current trends in the exciting field of fuel cell development at the system level in our webinar and find out how MicroNova and AVL are collaborating to find solutions to the challenges in FCCU development using simulation and HiL and SiL environments.

PEM fuel cells offer one of the most promising technology paths towards future emission-free mobility. Market needs and customer expectations regarding system performance, durability and costs lead to a variety of challenges for PEM fuel cell engineering.

The safety of the vehicle battery system during hazardous events is of critical importance. In this webinar, our experts discuss the challenges the automotive industry faces regarding battery safety and how to tackle them by efficiently combining testing and simulation.

When optimizing complete vehicles, it is essential to take interdependencies between the individual systems into account. This results in additional complexity for the development process.

Thermal design is an important component in the battery development process, since temperature has a strong influence on the electrochemical processes in the cell. With AVL eSUITE™ you have the possibility to design the thermal system and to detail it afterwards. We will show you how it is done.

With the ever-increasing demands on the internal combustion engine (ICE), engineers are constantly faced with new challenges in the design of modern intake and exhaust systems.

The balancing of vehicle attributes such as performance, efficiency, drivability, and comfort is becoming increasingly complex with the multitude of different and new vehicle concepts.

It is essential to choose the correct cold-start strategy to successfully start a PEM fuel cell system at sub-zero temperatures.In this free, 60-minute webinar, AVL's Dr Reinhard Tatschl and Dr Christoph Pötsch present a multi-physical system simulat

The decision on the type of powertrain is made on the basis of the basic characteristics that a vehicle should ultimately have. Electrified vehicles have proven themselves for short distances and city traffic. For long distances, the classic combusti

The race for the best battery cell format is still open, with all designs used in automotive applications from cylindric to pouch and prismatic approaches.In the second instalment of this two-part webinar series, AVL's Jürgen Schneider and Dr Jan Ric

The race for the best battery cell format is still open, with all designs used in automotive applications from cylindric to pouch and prismatic approaches.

PEM fuel cells offer one of the most promising technology paths towards emission-free mobility.

In this webinar, we present our solution for model-based calibration of gasoline engines. The basis of the new approach is the combination of the AVL engineering enhanced solution with the AVL CRUISE™ M crank-angle resolved cylinder model.

During the concept development phase, engineers often struggle to find realistic component data in order to parameterize their simulation models. Most of the time, they operate with generic data not representing reality.

The safety of the vehicle battery system during hazardous events is of critical importance.

When developing a battery for an electrified vehicle, temperature presents a particular challenge: If the temperature drops, performance decreases and charging problems may occur. Elevated temperature levels can lead to overheating and damage to the

In the third and final part of this webinar series, AVL and Batemo experts put everything explained in the first two sessions into practice.

In part two of this three-part webinar series, AVL and Batemo experts put simulation-based battery system development to the test and analyze three examples: fast-charging, cell aging and module cooling.

"More calibration tasks in less time with limited budgets.” This difficult framework is motivating OEMs to frontload as many processes into a virtual environment as possible.

With vehicle electrification, the competition to design and manufacture the most efficient powertrain possible is stronger than ever - with many hurdles to overcome.

In part one of this three-part webinar series, AVL and Batemo experts discuss how their high-precision physical, parameterized and validated battery cell models represent a breakthrough in battery development.

More than ever the automotive industry is under pressure to reduce emissions from internal combustion engines. To meet current and upcoming legislation goals, exhaust gas after-treatment systems must be highly effective right from engine start.

For many years, the automotive industry has been under constant pressure to reduce emissions from internal combustion engines.

The pace of change that the automotive industry has seen in recent years is unprecedented. Almost every new vehicle is electrified to a certain degree, ranging from mild hybrids to battery and fuel-cell electric vehicles.

2020 is the first year in which automakers need to meet fleetwide CO2 targets.

The need to reduce time to market for electrified powertrains is increasing rapidly due to the latest CO2 regulations. Shortening the development time of the battery is a key factor for the entire vehicle development. In order to optimize the perform

Frontloading is an effective measure to shorten product development cycles. It is particularly important in the powertrain development of fuel cell electric vehicles (FCEV) featuring multiple physical domains.

Hybrid Electric Vehicles (HEVs) combine the best of two worlds: a long range possible through an internal combustion engine and lower consumption and emissions through electrification.

With the rise of new powertrain technologies, the comfort of the passenger in the cabin and the energy management of the air conditioning system are becoming increasingly important.

AVL offers tailored simulation solutions to support engineering tasks during the fuel cell development process to achieve a short time to market.

To optimize the performance, efficiency, hazard prevention and lifetime of a battery in all relevant real-world scenarios, we have to investigate on multiple levels.

OEMs that succeed in quickly bringing electric vehicles (EVs) or hybrid electric vehicles (HEV) to market are in a strong position to dominate the industry. An integrated simulation approach is key to accelerating their development via frontloading.

This Webinar demonstrates the usage of system simulation throughout the development process of a battery electric vehicle.

This Webinar demonstrates the value of system simulation for the optimization of the propulsion and energy systems of marine applications.