In order to satisfy the latest emission legislations, OEMs have to downsize their engines and introduce additional systems which help to reduce the footprint of an ICE vehicle. Due to this development, the crankshaft as a main component of an ICE, is exposed to very high loading conditions. In this webinar, you will learn how to efficiently perform crankshaft durability evaluation. Flexible Multi-Body Dynamics Simulation

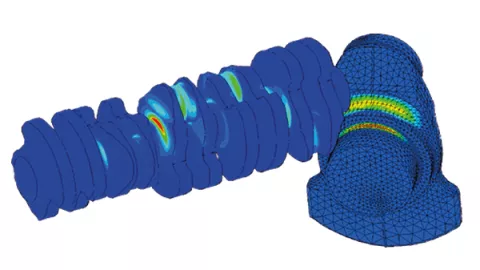

Crankshaft durability evaluation is one of the standard simulation tasks in the powertrain development process. AVL has developed several proven workflows which are performed throughout the automotive industry on a daily basis. By using AVL EXCITE™ Power Unit it is possible to export realistic crankshaft loading conditions considering bending, torsional and axial vibration as well as gyroscopic effects. In this Webinar, you will learn about the different approaches for crankshaft durability evaluation depending on the modelling level.