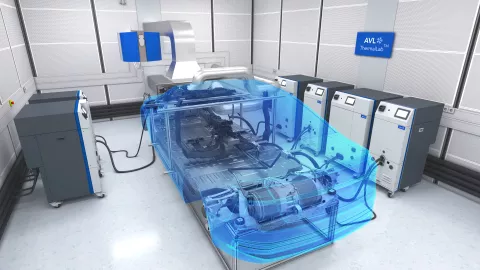

Brick-and-Mortar Solution

We distinguish between brick-and-mortar and modular construction projects. For brick-and-mortar projects, which are traditionally constructed on-site using concrete methods, our focus is on providing state-of-the-art measurement and testing technology. In addition, we provide essential building services directly tied to the project and offer comprehensive conceptual planning for the entire construction process. Depending on the specific needs and market conditions of our clients, we also have the capability to deliver the physical building itself.

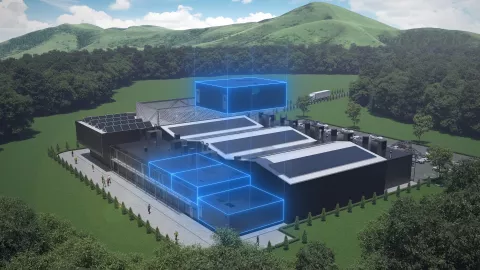

AVL Tech Center Modules

Our modular construction projects feature prefabricated modules, including containers, that are meticulously pre-assembled at our facilities. Each module is equipped with integrated mechanical, electrical, and plumbing (MEP) systems, as well as measurement and testing technology. Delivered to the end customer as a complete, ready-to-use module, our approach significantly accelerates the construction process. By shifting interface risks from the construction site to our controlled environment, we ensure risk reduction and enhance project efficiency.

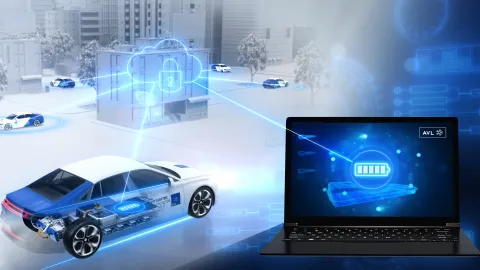

The AVL Tech Center Solutions offers and executes projects with a holistic view of the entire scope. We combine various test systems and find the best way to size our customer's facility - as large as necessary, as small as possible, to create the best solution.”

– Andreas Bohmann, Solution Engineer, AVL List GmbH