Aiming at a drastic CO₂ reduction in industry and mobility, the world is currently facing the challenge of producing green hydrogen at affordable prices and in sufficient quantities.

Solid oxide electrolysis is a promising technology for hydrogen production in the context of renewable energy systems, mainly due to its high efficiency, flexibility and environmental sustainability.

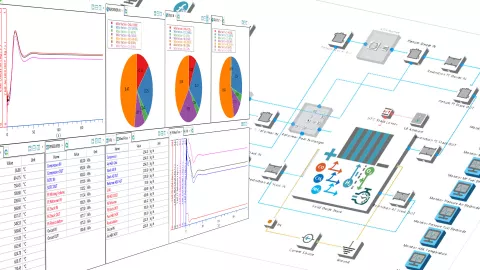

In Solid Oxide Electrolyzer Cell (SOEC) system development, engineering efforts are concentrating on the classic goal: a reliable, long-lasting system with maximum performance. To achieve the related target objectives in a fast and efficient manner, a simulation supported development approach is required - from the system design to the dimensioning of the Balance of Plant (BoP) components to the definition of the operating strategy.

Specifically, the virtualization of the main development steps brings major time- and cost-savings: Simulation can be used right from the definition of the system architecture and component selection. Further on in the process, virtual testing of various use cases such as leakages, insulation, transient warm-up cycles and, in particular, the SiL aided development of control functions can reduce the testing time massively.

In this webinar, we will show you how you can meet challenging SOEC system development requirements by adopting multi-physics system simulation.

Thanks to the support of all necessary thermodynamic effects and the comprehensive electrochemical stack model supplemented by dedicated BoP component models, you can use our system simulation tool AVL CRUISE™ M in all these development steps. Special feature: To parameterize the models automatically, you can use the wizard offered in the software. Or let the generator create a realistic SOEC model with a defined size that is immediately ready for use.

Watch now

Ales Cvikl

Team Leader Thermodynamics

AVL Advanced Simulation Technologies