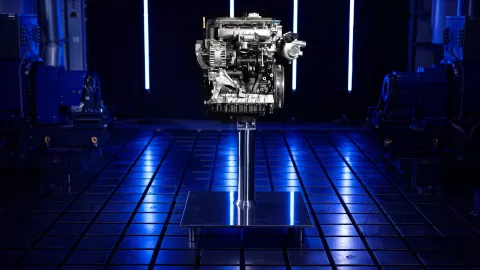

410 Hp from 2-Liter Displacement – Prototype of the H₂-ICE Race Engine from AVL RACETECH Proves Itself on the Testbed

The motorsport department of AVL is celebrating the next milestone on the road to a zero-emission future of motorsport. The prototype of a hydrogen-powered, two-liter turbo engine – built by AVL RACETECH – was put through its paces on the testbed and confirmed the top values calculated previously in simulations: with a specific power density around 205 hp per liter (150 kW per liter), the engine achieves a highly competitive level in the world of motorsport. This is made possible by, among other things, an intelligent PFI water injection to moderate combustion.

Graz, Austria, October 2023: Up until now, hydrogen combustion engines (H₂-ICE) have been somewhat renowned for low performance figures and lean-burn. AVL RACETECH is banishing that “preconception”. Over the past few months, the motorsport department at AVL has developed an innovative H₂ racing engine in cooperation with the Hungarian HUMDA Lab. For AVL RACETECH it is the first race engine under its own name. On one of the engine testbeds modified for the use of hydrogen at the AVL headquarters in Graz, a prototype of the hydrogen-powered, two-liter turbo engine achieved a top figure of 410 hp (301.7 kW) with an engine speed of 6,500 rpm. The engine generates 500 Nm of torque at 3000 - 4000 rpm, that corresponds with a mean pressure (BMEP) of 32 bar.

The features include an intelligent PFI water injection, which injects additional water into the engine’s intake air, in order to avoid unwanted premature ignition, which can damage the engine. The air-fuel ratio (lambda) is 1 (stoichiometric combustion), meaning it is no longer in the lean range. The air demand, which is lower than with lean combustion, is covered by using a wastegate turbocharger designed specifically for that purpose.

AVL had performed detailed simulations in advance, which displayed an excellent correlation with the results recorded on the testbed. The next milestone in the development is to test the new engine concept in a car on the racetrack.

Project leader Paul Kapus, Manager Development Spark Ignited Engines: “At the end of 2022, we announced for the first time that we would be working on a two-liter, hydrogen-powered racing engine with stoichiometric combustion and PFI water injection. Our goals were 500 Nm of torque and an output of up to 300 kW (specific output 150 kW/l). We are proud to have been able to validate those figures on the testbed.”

Ellen Lohr, Director Motorsport AVL: “The results achieved by our H₂ racing engine confirm that we are able to deliver an extremely competitive package with this technology. The goal of AVL RACETECH is to lead motorsport into a sustainable future. With the development of the first racing engine developed under our own name – a high-performance H₂-ICE – we have taken another step closer to achieving this vision.”

With more than 12,200 employees, AVL is one of the world's leading mobility technology companies for development, simulation and testing in the automotive industry and in other sectors such as rail, shipping and energy. Based on extensive in-house research activities, AVL delivers concepts, technology solutions, methodologies and development tools for a greener, safer and better world of mobility and beyond.

AVL supports international partners and customers in sustainable and digital transformation. The focus here is on the areas of electrification, software, AI and automation. AVL also supports companies in energy-intensive sectors on their way to green and efficient energy generation and supply.

AVL's passion is innovation. Together with an international network of experts spanning 90 locations with more than 50 competence and development centers worldwide, AVL is driving the future of mobility. In 2024, the company generated a turnover of 2.03 billion euros, of which 11% was invested in R&D activities.

For more information: www.avl.com

AVL RACETECH, is the global motorsport division of AVL. For more than 20 years, AVL RACETECH works with customers in more than 17 racing series across the globe in the fields of engineering, testing, simulation and manufacturing. It is a key supplier for teams in the most respected racing series, from Formula 1 and NASCAR to MotoGP, and provides state-of-the-art technology and services to the motorsport world. AVL RACETECH views motorsport as a platform for innovations. We transform our team's expertise into technologies and solutions to `innovate-accelerate-lead`.

For more information: www.avlracetech.com

Contact

Christina Ettel

Marketing Specialist Racing

E-mail: Christina.Ettel@avl.com

Our mission: HUMDA Lab aims to be an incubator and leading organization for the Hungarian national motorsport research and development activities. Our story: We established the Lab in 2021 as a nonprofit organization focusing on scientific research, knowledge transfer, as well as high-tech and infrastructural developments in motorsports (and in a broader sense in mobility and automotive industry). In 2023 we became a subsidiary of Széchenyi István University Foundation, the managing authority of the University in the city of Győr, Hungary. Our headquarter is in Budapest with a branch office in Zalaegerszeg and Győr. We are a dedicated team of researchers, automotive system engineers, motorsport professionals, software developers and project managers with strong passion for racing.

M&H, based in Ilz, Styria, is counted among the international innovation leaders in the field of additive manufacturing. M&H's competencies include consulting, engineering, as well as 3D metal printing and finishing of complex high-end components. To achieve this, the 30-member, internationally successful niche player also leverages its long-standing expertise in conventional turning and milling processes. M&H is in demand as a partner in international motorsports, as well as in the aviation, mobility, and hydropower industries. "We excel from prototyping to serial production," explains M&H CEO Patrick Herzig.

VENTREX is a global leader in automotive valve solutions, designing and producing multiple types of valves and electronic pressure regulators for alternative powertrain systems and cooling circuits. Committed to create solutions that improve safety, efficiency, comfort and environmental footprint, we partner with our customers around the world to help them stay at the forefront of automotive innovation and shape the next generation of mobility.

As an engineering firm with affiliated manufacturing, WEISSGERBER engineering GmbH develops and produces metrological components and devices, as well as ignition technology for spark-ignited combustion engines, in close contact with the customer. High production depth allows the company to react quickly to customer requests and requirements. The core competencies include the development and small-scale production of components and devices for pulse and high-voltage technology, to be used under extreme environmental conditions.

- EN,

- EN,

- EN,

- EN,

Stay up-to-date as a journalist with our latest press releases concerning company updates, research projects, our latest developments, and more.

Download our fact sheet to get a comprehensive overview about what we do as well as our latest company figures.