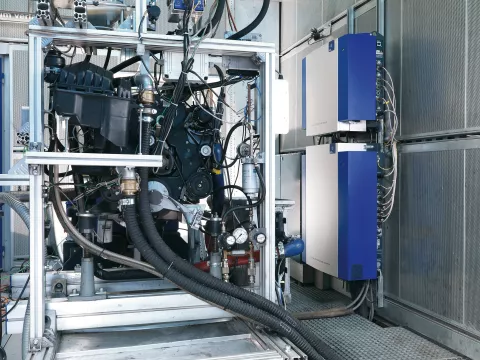

Stricter regulations with regard to CO2 and fuel consumption mean that engine maps have to be optimized very closely to the limits. At the same time, the number of engine maps needed due to new engine concepts and fuels is increasing. Transient measurements – as possible with the AVL Fuel Mass Flow Meter and AVL Fuel Temperature Conditioning Unit - reduce the time it takes to perform this optimization.

Highly precise and boasting excellent temperature stability, the modular design allows them to be combined with other systems. Accurate results even at low flow rates and with short measurement times make this a dynamic and flexible solution.

Fuel consumption is determined continuously in kg/h via direct mass flow measurement. Unlike volumetric measurement methods, it is not necessary to also determine the density alongside the measurement of the gravimetric or specific fuel consumption. This allows fuel consumption to be assessed up to an accuracy of 0.12 % for the entire system under real test bed conditions.

| Property | Type AVL 735S/753C |

|

Measurement principle |

Mass flow |

| Measurement ranges Mass flow |

0 … 125 kg/h |

| Measurement uncertainty Mass |

≤ 0.12 % (acc. to DIN 1319) |

| Measurement frequency | 20 Hz (analog) |

Accurate and Stable

Measurement accuracy of 0.12% through direct mass flow measurement. High temperature stability of the fuel conditioning system.

Open System

Open continuous measurement system with no pressure changes in the measurement circuit due, for example, to temperature fluctuations.

Safe Operation

Built-in accuracy check and calibration according to ISO 9001.

Easy Installation

The system is designed to be easily installed for all gasoline or diesel injection systems using a specially developed pressure control system. This makes it possible to replicate realistic vehicle conditions on the testbed.

Testbed Versatility

A measurement range from 0 to 125 kg/h for engines up to 600 kW offers testbed versatility. Additionally, a calibration interval of 3 years and a built-in accuracy check compliant with ISO 9001 make this a robust and reliable system.

Measurement Accuracy

Fuel temperatures between 10 and 80°C can be preselected, guaranteeing high measurement accuracy and temperature stability. Furthermore, gas bubble separation and a bubble monitoring system ensure that the fuel supply is bubble free.