The electrified powertrain and testing requirements are driving up both complexity and costs. To overcome these challenges, new solutions are needed to reduce costs and accelerate time-to-market while maintaining high quality. With extensive internal AVL E-Axle development expertise and decades of experience in production testing, we have designed AVL E-Axle test systems based on simplicity and robustness.

AVL offers customized test system solutions for End of Line (EoL), Quality Assurance (QA), and Conformity of Production (CoP) testing, meeting the demands of modern e-mobility.

- AVL E-Axle TS™ End of Line

- AVL E-Axle TS™ Quality Assurance

- AVL E-Axle TS™ Conformity of Production

We support our customers with customized testing processes and appropriate testing solutions, defined by following characteristics:

Wide Power Range

-

Solutions for passenger cars, light-, mid and heavy duty vehicles

-

Standard solutions for power ranges up to 440kW (per wheel)

-

Power ranges above 440kW (per wheel) on request

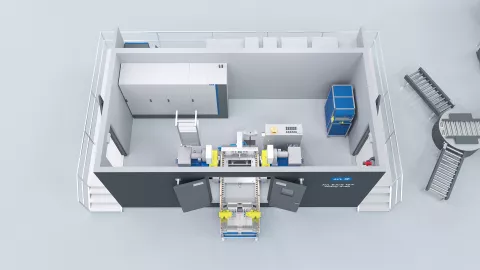

Flexible Layout

-

Small footprint

-

Brick & mortar or protective enclosure

-

Easy integration into existing production environment

Variable Testing Workflow

-

Preparation: Manually, up to fully automated

-

Handling: Trolley, conveyor, robot or AGV

-

Testing: Manual through match plate or automatically connected

At AVL, we see our production testing solutions as an important factor for both an effective production process and high product quality – a major pillar our customers can rely on.”

– Robert Nemeth, Department Manager, AVL List GmbH