With AVL, customers gain access to a full package of engineering and design services for PEM electrolyzer stacks, complemented by a global supplier base for stack materials and system integration. From initial concept to series-production readiness, we deliver tailored solutions that meet customer-specific requirements. Our offering includes:

- End-to-End Stack Development: From component materials to complete stack designs, from engineering to experimental validation, from concept to start-of-production.

- Proven PEM electrolyzer stack reference design: Utilizing AVL’s in-house stack design as starting point for commercial stack development projects

- Validation and Testing: Our global test centers are equipped with state-of-the-art test systems and proven testing methodologies (DVP) to validate and verify your PEM electrolyzer stack, and to guide you to a series-production release with confidence.

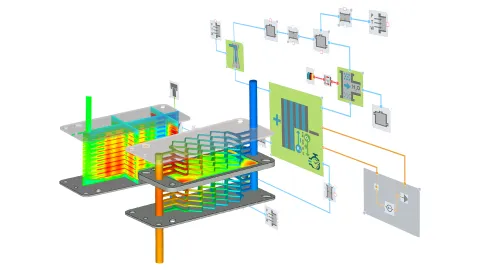

Stack Design and Optimization

Our experience in stack development includes completely custom-designed stacks as well as optimizing or troubleshooting existing stack designs. Cutting-edge models and simulation tools are an important element in achieving this.

Design Verification

We define Design Verification Plans (DVPs) based on our deep understanding of fuel cell and electrolyzer technology, and the failure modes and effects associated with these technologies. We execute testing service with our in-house electrolyzer testbeds.

System Optimization Support

In addition to designing complete systems, we excel in refining and enhancing existing systems. Whether it’s improving efficiency, extending lifespan, or addressing specific performance challenges, we deliver failure analysis, consulting, and engineering solutions.

Operating Strategy

Every stack design requires a well-balanced operating strategy to assure efficient operation, while making sure that the stack meets lifetime targets. Our stack/system interface team has the expertise and the experience to define the operating strategy your stack needs.

Material Characterization

We specialize in material characterization for electrolyzer stacks, providing critical insights for stack design and performance optimization. Our expertise spans beginning of life and degraded material analysis at macro and micro levels, supporting simulations, failure analysis, and benchmarking. Equipped with advanced tools and expert engineers, we drive durable, high-performance, cost-effective stack solutions.