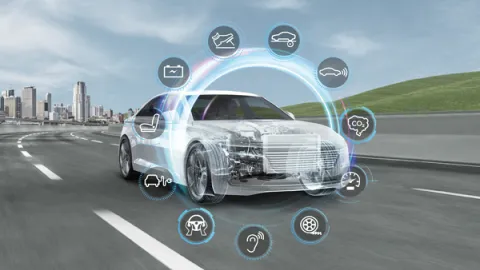

No matter whether you are planning function or system development, optimization of an attribute, or a complete vehicle. Our “attribute engineering” gives you a consistent methodology.

To guarantee maximum future security, we perform comprehensive technology scouting, which illuminates technical and functional innovations, as well as cost factors. Our internal AVL benchmarking provides you with all the information you need to know about your competitors.

During target setting, we profile your product and start the virtual development phase. We use the desired goals to simulate individual functions or the overall vehicle. We use virtual assurance early on to support your frontloading. We are also your single source for concept definition, integration, evaluation of quality criteria, and release testing.

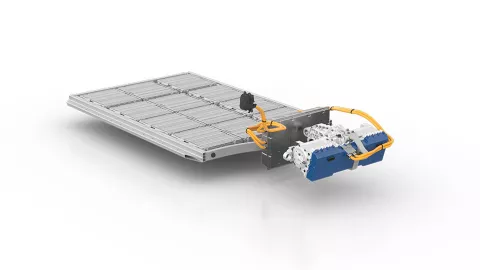

Battery electric vehicles require optimum integration of the battery into the vehicle. To complete this task efficiently, at AVL we have been developing the vehicle around the battery for quite some time now. In doing so, we are also increasing the space for energy storage.

Optimizing Costs

The battery is responsible for the bulk of the costs of the overall vehicle. To keep production costs within reason, the right propulsion system decisions need to be made very early on.

At AVL, we have been working on all major issues in the automotive industry for more than 70 years now, which enables us to provide you with comprehensive experience when it comes to the propulsion system. Our frontloading approach allows us to clarify many questions very early on using simulation, which reduces development costs.

Sustainable Focus

Guaranteeing sustainability requires implementing new technologies and materials, and integrating everything into the vehicle homogenously. Weight reduction is also a major factor when it comes to energy efficiency. With our holistic view of the vehicle, we revise and optimize existing vehicle concepts for you from all angles

The current multitude of propulsion system variants means a good overview of the competition and the market situation is needed.

Thanks to our diverse benchmarking activities, we know exactly what end customers want. Our extensive database provides in-depth insights, particularly in the functional area. The values from the benchmark are incorporated into target setting and form the basis for positioning your product optimally compared with the competition.

- Comprehensive benchmark database with more than 500 vehicles – very detailed in the functional area

- Virtual development methodology with functional orientation

- Huge partner network with other engineering service providers

Virtualization is a key enabler for the fast transition from component-oriented to functional-oriented vehicle development.

Through our comprehensive AVL Global Vehicle Benchmarking program, you will gain in-depth understanding of the latest trends in vehicle development. Our standardized testing procedures, assessment and evaluation methodology, as well as the related metrics and KPIs provide you with a detailed technical analysis of your competitors’ vehicles.

When developing your vehicle, it is crucial to describe all functions precisely, and to balance their interaction optimally. The result is a consistent target system as a base for your optimized vehicle development.

From brake emission measurement to targeted improvement measures and low emission braking system and concept development – AVL offers comprehensive brake attribute engineering for both cars and trucks.

As an independent service provider, we take your mobility to the next level.

The chassis is the interface between road and vehicle. It ensures dynamics, driving comfort, and stability. At AVL, we cover the entire spectrum of vehicle development – from predevelopment to series production and from component to overall system.

We have technology and development centers around the world. No matter whether you are in Europe, Asia, North America, South America, or Africa – we provide local support.

70+

years of experience

11,500

employees worldwide

65 %

engineers and scientists

10 %

of our revenue invested in research and development

1,500

patents

96 %

export rate

News

Moving steadily into the future: Find out what’s brand new in the field of vehicle development comfort.

- EN,

With the new vehicle engineering center, AVL established a unique engineering facility to test conventional and future vehicles in Zalaegerszeg, Hungary.

- EN,

Innovative Test Infrastructure for Driver Assistance Systems and Autonomous Driving