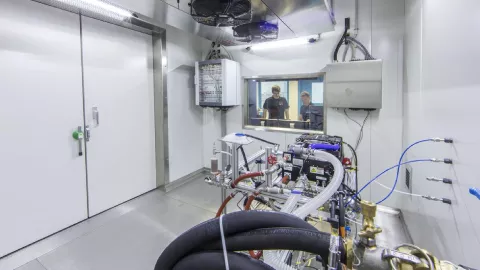

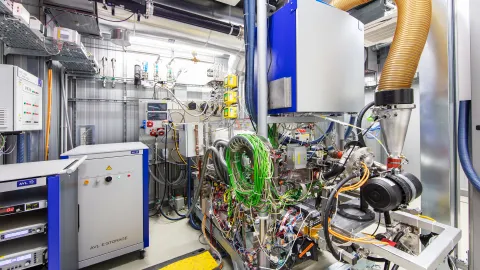

Our containerized electrolysis system testbed denotes a holistic testing solution for complete electrolysis systems in the range of up to 5MW that seamlessly integrates into our proven toolchain for automation, calibration, simulation and data analytics. AVLs electrolysis system testbed is the ideal development platform to front-load engineering tasks and improve the electrolysis systems robustness and efficiency.

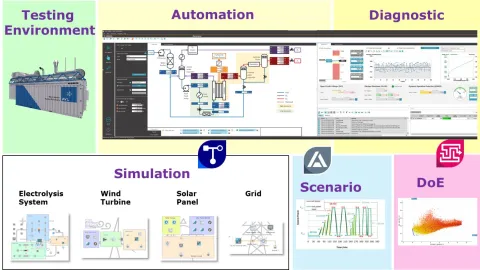

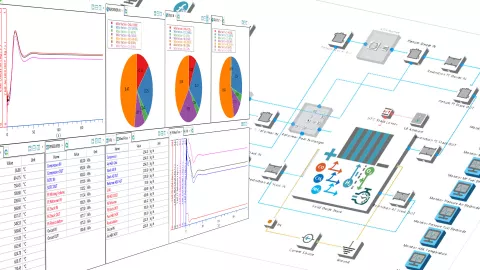

Testbed Automation

AVL's electrolysis system testing solution seamlessly integrates into our Automation and Data Analytics Toolchain. With such a high degree of automation, complete testing scenarios and the necessary data post-processing can run automatically, generating valuable insights and freeing up engineering hours for the job that matters: improving the unit-under-test.

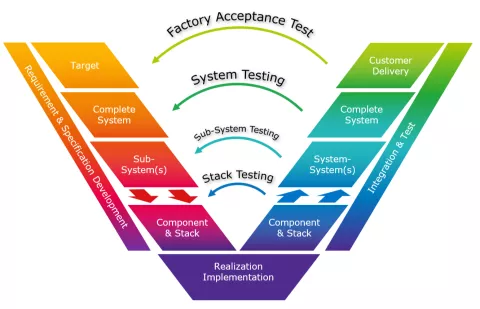

Upfront Verification and Validation Platform

In future, the end-customer requires well proven and validated electrolysis systems, as the overall robustness, efficiency, guaranteed up-time and degradation rate are vital for an end-customers business case. AVL's electrolysis system testbed is the ideal solution and development platform to improve on the vital key-performance-indicators on the one hand, and on the other hand, to verify these relevant performance targets to an end-customer upfront.

Calibration and Optimization Toolchain

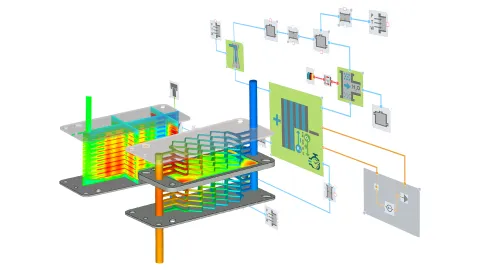

Even the most well-designed machinery is only allowed to perform what it’s operation strategy and control system allows it to. Although nowadays a lot of these development activities can be achieved using digital twins and simulation to parallelize the control system development, there is still the need for final calibration and optimization on the real unit under test to unlock its full potential. The AVL calibration toolchain is suitable to start calibration in the virtual world and can seamlessly be carried over to the actual unit under test on the testbed for final calibration.

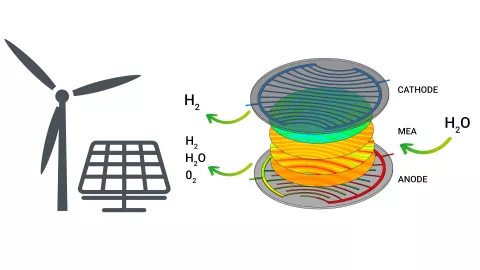

Simulation Augmented Testing

A central part of fit-for-function testing is to verify that the electrolysis system is capable of performing under it’s intended application environment. As the electrolysis system is in many cases part of a bigger H2 network, consisting of multiple producers, consumers, compression stations, storage and purification systems, cross coupling effects and cross influences of different sub-systems are to be expected. To test for these coupling effects, the application environment – including the electric grid – can be simulated and the boundary conditions (i.e. O2 and H2 back-pressure, thermal conditions and grid conditions) can be actively controlled on the testbed to mimic the applicational environment.