Efficient Validation Through the Use of Highly Automated Testbed Systems

- Expert Article

Marko Decker

Department Manager, Testing Efficiency & Methods

For more than five years, Marko Decker has been responsible for efficiency on the testfield. As a result, his department develops tools and methods aimed at highly automated testing using DevOps techniques. His current focus is on electric vehicle (EV) development and E/E testing.

The Three Pillars of Efficiency

Pillar 1: Processes

Model-based engineering and DevOps to streamline the validation workflow and ensure efficient collaboration across teams.

Pillar 2: Tools

Utilizing the right tools, especially for test case generation and automation. Reduce manual effort and enable rapid iteration and scalability in the validation process.

Pillar 3: Test Environments

Proper testing environments tailored to specific test cases. Leveraging advanced testbed systems to ensure accurate and reliable validation.

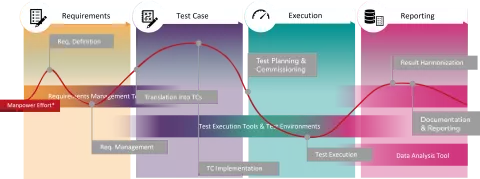

To address the challenges of EV validation, we must examine the entire verification and validation workflow. lt begins with well-defined requirements, which serve as the foundation for efficient validation. While it is not always possible to obtain perfect requirements, proper requirements engineering is crucial for optimizing the validation process. Manpower efforts in the verification and validation workflow are high and the task of manual test case implementation very time-consuming. However, by optimizing individual steps and utilizing DevOps, we can significantly enhance overall testing efficiency. DevOps facilitates seamless integration of test requirements, test case implementation, test execution in specific environments, and reporting back to the life cycle system.

Test Case Generation and Requirement Management

By linking test cases to specific requirements, we can verify the fulfillment of those requirements and identify any inconsistencies or missing elements. This approach enables us to adapt to changing requirements effectively, ensuring that all related requirements are updated accordingly. The results obtained from these tests are thoroughly evaluated, compared against the requirements, and used for making adjustments and fixing any identified bugs.

Minimization of Test Cases

These variants may differ in power rates or types of drives. Ensuring that all variant-specific requirements are fulfilled, needs extensive testing. The first step is to identify the attributes that distinguish different variants of the Unit Under Test (UUT). These attributes capture the variations between the UUT variants, such as battery type, market segment, or vehicle weight.

By assigning relevant values to these attributes, we can effectively differentiate the UUT variants. This means that with one UUT variant, we can validate the requirement for all other UUT variants, saving time and resources. On the other hand, certain tests, like AC charging, may be sensitive to attributes such as battery type and market segment. In such cases, if multiple UUT variants share the same battery and target market, we can perform the test with any of those variants, effectively reducing the number of required tests.

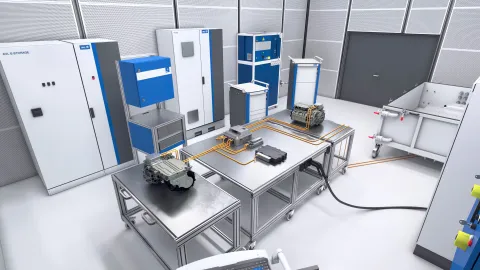

Powertrain and Vehicle-in-the-Loop Tesbeds

The AVL powertrain testbeds, known as PaViL (Powertrain and Vehicle in the Loop), offer flexibility and scalability. The PaViL testbed can be equipped with up to five dyno machines, so that various vehicle configurations can be tested. A semi-automatic setup process, including mechanical and electrical connections, ensure a quick testbed commissioning. Additionally, our testing automation framework enables automatic test execution and data acquisition, ensuring consistent and reliable results.

As recently more and more vehicle features are activated throughout the touchscreen of the main HMI, a robot system was developed to allow an un-manned operation. Our robot system, with a special gripper, enables us to perform not only touch movements but also cover wipe and zoom functions on the touchscreen display. This level of automation allows us to mimic user interactions accurately and efficiently.

Importance of Well-Defined Test Cases

Efficiency in the validation process heavily relies on well-defined test cases. We have realized that implementing test cases on different testing environments can be time-consuming, accounting for nearly 60 % of our efforts. To optimize this process, we have standardized the specification of test cases using a semi-formal, machine-readable notation. This standardized approach enables us to automatically generate test executables for multiple environments, saving valuable time and effort. Additionally, we have established highly automated data processing capabilities, seamlessly integrated with our life cycle management tool, to ensure efficient test evaluation.

Seamless Integration and DevOps in Testing

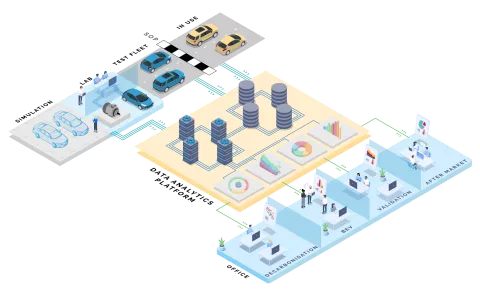

To streamline the testing workflow and handle the multitude of tests required, we have adopted a seamless integration approach, drawing inspiration from the software development industry's DevOps test cycles. This approach connects and organizes various test attributes, including test requirements, test cases, and models. By leveraging continuous integration, continuous deployment, and continuous testing, we achieve traceability, transparency, orchestration, and autonomy in the verification and validation process.

Our system testing approach on the HV Powertrain Testbed and HV System Testbed provides significant benefits. The high reproducibility of these testbeds facilitates fast and straightforward failure pinpointing, leading to more efficient troubleshooting. Moreover, the high degree of automation enables 24/7 operation, ensuring continuous testing and higher test coverage compared to traditional vehicle road testing. Through the utilization of these testbeds, we can reduce the number of physical prototypes required by up to 50 %.

Big Data Analytics for Efficient Data Processing

With the extensive data output generated from our testing activities, we recognized the need for efficient data processing. AVL Data AnalyticsTM, which incorporates big data methods, allows us to process large volumes of data within a short timeframe. This platform empowers engineers to analyze data comprehensively, identify outliers, and gain valuable insights that contribute to efficient decision-making.

Conclusion: Efficient Development to Deliver Top-Quality Vehicles to Market

Our seamless integration approach, combined with DevOps principles and the utilization of advanced testing technologies, enables us to achieve faster time to market while maintaining high quality standards. By standardizing test case specifications, automating test execution, and employing data analytics, we optimize efficiency and improve the effectiveness of our automotive testing processes. This approach not only reduces costs but also enhances the overall development cycle, ensuring delivery of top-quality vehicles to market efficiently.

Related Topics

We are constantly working on new solutions. The following might be interesting for you:

News

Moving steadily into the future: Find out what’s brand new in the field of energy sustainability.