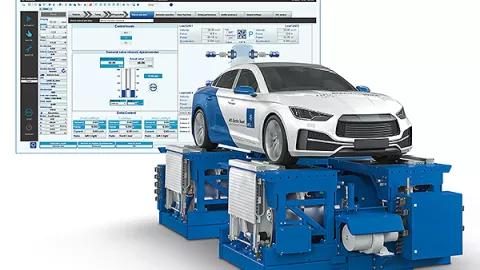

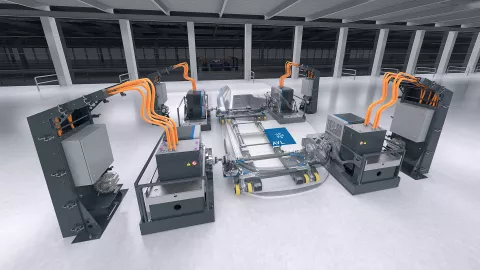

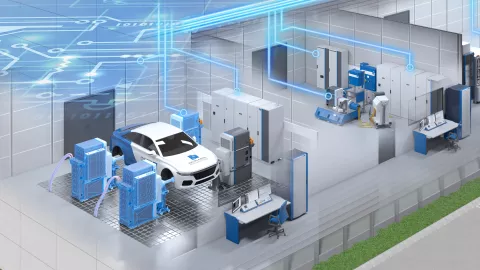

Our modern vehicle test systems are built to validate and test any vehicle type from motorcycles to 6x6 HD trucks with varying velocities, forces, and power classes, as well as voltage and current levels in electrified vehicles. The vehicle testbeds simulate velocity and force for the vehicle, emulating real-world driving conditions, road data replication, or time-lapsed testing. The optimized toolchain of our hardware and software significantly reduces the duration of the design and validation process. Tests can be executed in a reproducible laboratory environment, simulating any environment with fast setup times. This minimizes the time, risk, and costs of on-road testing. Results can be used either to valide models in early development stages, or for final performance evaluation, certification, and COP testing.

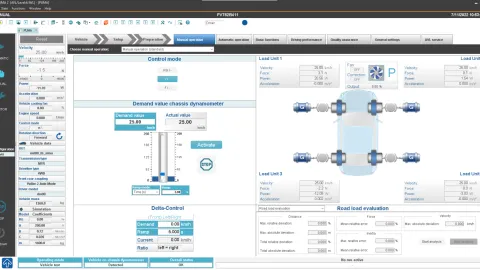

Using our AVL PUMA 2™ automation software platform ensures synchronized measurements and data consistency from every integrated device. This high level of data quality – combined with the system’s precise measurement and control and simulation capability – leads to the utmost precision of the measurement results achieved. Moreover, all calculations, protocols, and therefore measurement results, are approved by the leading authorities, and our systems can be certified according to ISO 17025. Thus, testing results with AVL vehicle testbeds are guaranteed to be accepted by authorities, for example, for range or COP testing.

During this period of time, which is characterized by disruptive changes on an unimagined scale, with changes being far from complete, AVL vehicle test systems are THE reliable and proven solutions when it comes to final vehicle validation and compliance testing according to the latest legislations, from range testing up to EMC test for type approval.”

-- Roland von Gavel, Head of Business Development, AVL Zöllner GmbH