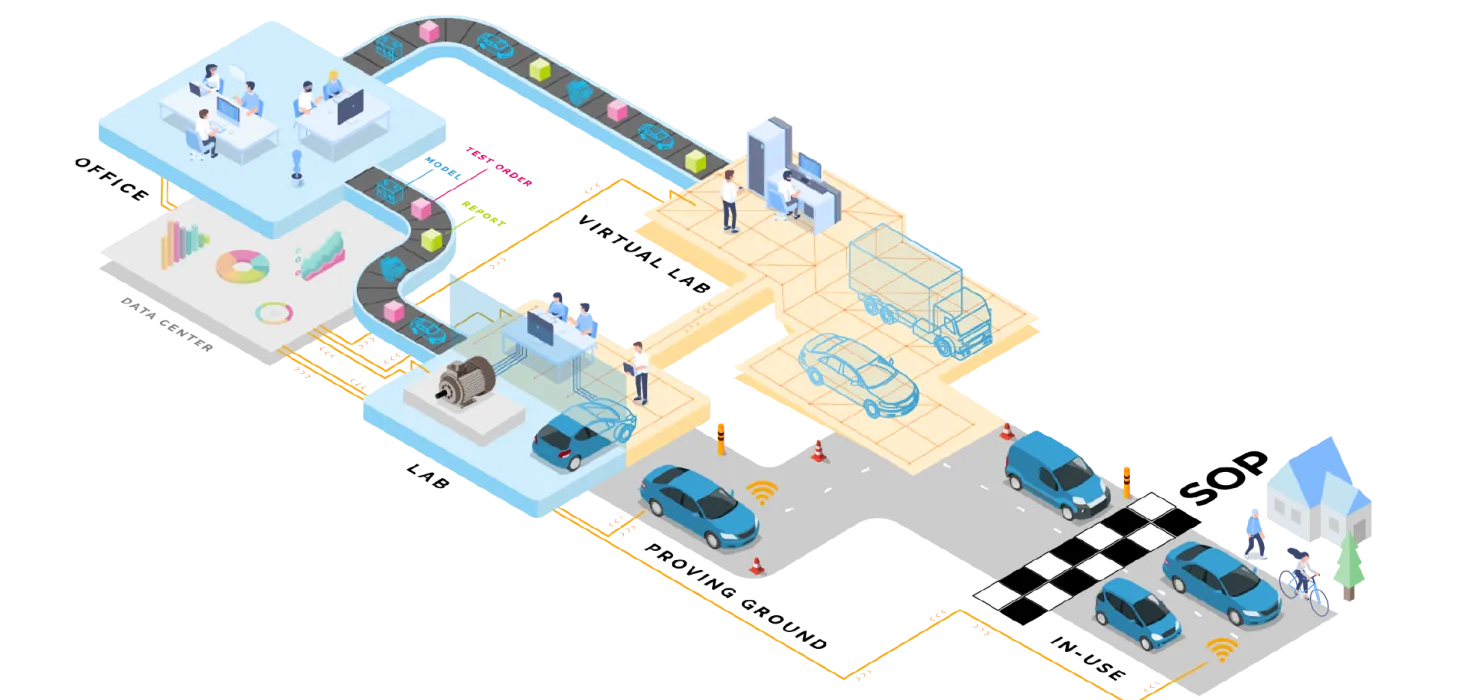

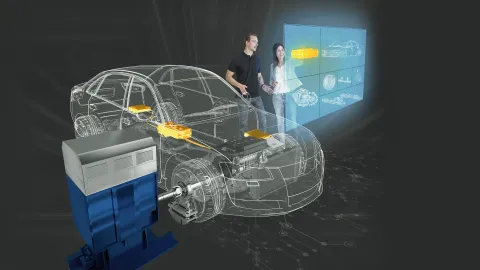

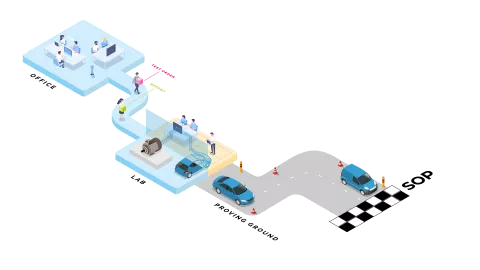

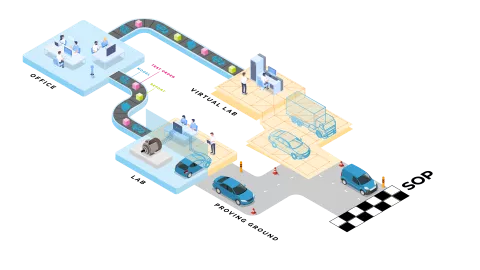

Virtual testing addresses these challenges head-on by offering a comprehensive and agile approach to development and validation. By harnessing the power of advanced simulation techniques and computational modeling, virtual testing enables engineers to explore a vast array of design configurations and performance scenarios within a digital environment. This capability not only accelerates development cycles but also significantly reduces costs by minimizing the need for physical prototypes and associated testing infrastructure

Furthermore, virtual testing empowers engineers to delve deeper into the intricacies of automotive systems, capturing nuances and interactions that would be challenging to replicate in traditional testing setups. From simulating complex thermal dynamics and structural behaviors to optimizing powertrain performance and vehicle dynamics, virtual testing offers unparalleled insights into the behavior of automotive systems under diverse operating conditions.

Virtualization has never been so important than now for accelerating the complex vehicle development. At AVL we employ it to help our customers shape the future of mobility.

- Gianluca Vitale, Global Business Segment Manager, Smart Calibration and Virtual Testing, AVL