As electrification advances, the need for efficient thermal testing and advanced vehicle thermal management systems (VTMS) grows. These systems play a crucial role in optimizing passenger comfort, extending driving range, and ensuring the durability of key components such as batteries, e-motors, and fuel cells. Effective thermal regulation is essential to maintain performance, safety, and long-term reliability in electric vehicles.

Modern electrified powertrains present complex thermal challenges due to fluctuating operating temperatures across different components. An optimized VTMS, supported by precise thermal testing, ensures efficient heat management, minimizes energy loss, and enhances vehicle efficiency and longevity. By addressing the specific thermal needs of batteries, e-motors, and power electronics, manufacturers can improve overall performance and accelerate innovation in e-mobility.

A highly efficient vehicle thermal management system (VTMS) is essential for maximizing energy efficiency and prolonging the lifespan of critical powertrain components. However, developing and optimizing VTMS solutions requires extensive calibration and testing, which can significantly increase development costs and extend project timelines.

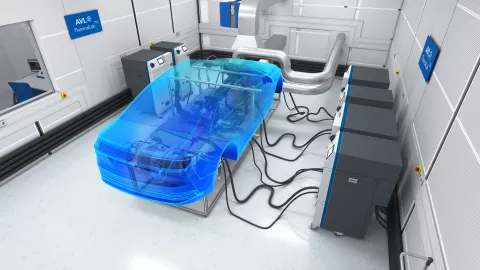

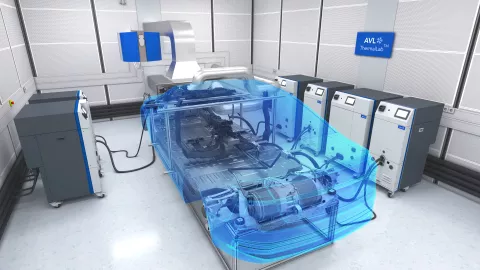

To overcome these challenges, AVL ThermalLab™ provides an advanced thermal testing environment designed to accelerate VTMS development. Offering unmatched flexibility, it allows testing of either the complete thermal management system or individual components under real-world conditions. Our ThermalLab streamlines the calibration and validation process, enabling faster development cycles, optimized system performance, and reduced costs.

Enhanced Efficiency

Streamline the development and testing of VTMS components to achieve optimal energy efficiency throughout the vehicle.

Cost Reduction

Reduce development costs by minimizing the need for extensive and expensive testing procedures.

Thorough Analysis

Analysis of the VTMS components and architecture for range and cabin comfort on the testbed.

Flexible Testing

Choose between testing the entire VTMS or focusing on specific components, providing tailored solutions for various development needs.

The AVL ThermalLab™ enables precise testing of complete thermal systems and individual components under realistic, emulated environments – independent from vehicle prototypes and weather conditions. With highly dynamic conditioning systems, it accurately simulates driving and environmental conditions, reducing development time and costs. The ThermalLab ensures that your VTMS is optimized for peak performance and efficiency.

System and Subsystem Testing

Using model-based testing, the ThermalLab optimizes the entire VTMS under dynamic conditions. The Unit Under Test (UUT) is the complete VTMS, includes powertrain coolant circuits, heating, ventilation, and air conditioning (HVAC) systems, and thermal management control units. Integrated into an emulated vehicle and a fully simulated environment, comprehensive testing can be performed in the lab more efficiently and cost-effectively than traditional road or wind tunnel testing.

Component Testing

Even without a complete VTMS, individual thermal components can be optimized using our ThermalLab model-based approach. The UUT is embedded in an emulated vehicle, while a hardware-in-the-loop (HiL) simulation replicates the rest of the thermal system and its environment. This allows components to be tested in different driving cycles, ensuring proper subsystem functionality and enabling pre-calibration of actuators on the testbed.

Modular Test System Design

Modular test system design enables solutions that accurately reflect customer use cases.

No Prototype Vehicles

No prototype vehicles required for the optimization of the entire VTMS.

Independent Development

Development is disengaged from weather conditions and regions.

Flexible Testing

Possibility of testing various VTMS concepts with different propulsion systems.

Climatic Chambers

Batteries, fuel cells and electric drives must operate safely and reliably in any environment. This means that they can be exposed to extremes of temperature and humidity that are difficult to replicate on a test track or in real-world road tests.Therefore, we have developed our climatic chambers. Our solutions safely and reliably simulate a wide range of harsh environmental conditions, providing high flexibility while minimizing system downtime. Their distinctive application-based design with pre-defined interfaces ensures seamless integration into existing testbeds.

Conditioning Systems

Gaseous and liquid media have a significant impact on the behavior of the UUT. Conditioning systems bring these media into a selectable and predefined range. Stable environmental conditions are essential to perform tests with high precision and reproducibility. These environments are conveniently and reliably provided by conditioned media. Our conditioning systems are characterized by their modular design, excellent functional expandability and compactness, making them mobile and versatile on the testbed.

With the AVL ThermalLab, we bring real-world conditions into the test lab – precisely, efficiently, and under controlled environments. This accelerates the development and validation of battery systems and fuel cells to a whole new level."

– Peter Priesching, Global Product Manager, ThermalLabs

A vehicle thermal management system has a significant effect on the energy efficiency of the entire vehicle and the durability of all components in the propulsion system, such as the battery and inverter. Highly efficient systems require extensive calibration and testing time at vehicle level, which has a huge impact on development costs and timing.

Battery packs, modules and cells, fuel cells, e-motor and e-axle solutions must operate safely and reliably in any environment. This can include extreme temperatures and humidity, which cannot be reproduced on the test track or in real test scenarios on the road. This is why we developed the modular AVL Climate Chamber.

Thermal conditions and environment of Units Under Test have strong impacts on real results in driving. For this reason, the thermal simulation must be as exact as possible – which can be achieved via deployment of high performing media conditioning systems.

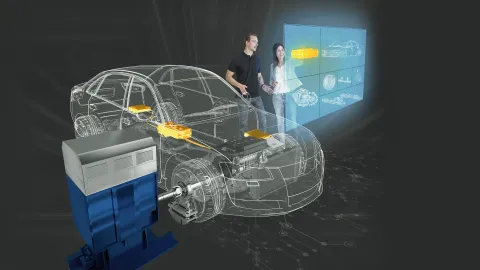

AVL X-meter helps you with in-vehicle energy balance measurement, range testing, precise re-charging energy measurement and pre-compliance tests.

New powertrain technologies require a higher data throughput rate in real time. AVL FEM 4™ enables you to measure all raw data relevant for the characterization of the unit-under-test.

A powerful open execution platform that connects simulation models to the testbed.

Your success is our goal. This is what we are aiming for and this is how we understand AVL Customer Services since decades. Our goal is not new, but the way how we do it, is constantly evolving.

As a global society, we are pushing hard to achieve a transformation to net-zero-CO₂ but without loosing energy security and our current living standards. The transformation in the mobility will come at cost, which endangers affordable individual mobility in the future. Doing nothing, however, will generate even higher costs.

- EN,

Up to 60 Percent Shorter Test Duration thanks to Direct Cooling and Automation

What kind of cars will we be driving in the future? These and other exciting questions around the topic of "Future Mobility" were addressed by more than 1,000 participants from 25 countries at the international 44th Vienna Motor Symposium. The tenor: Future automobiles will be CO2-neutral.

What are the future trends and where are where are we heading when it comes to the technological developments in the Austrian mobility sector. These and other exciting questions were addressed by Austrian Chancellor Karl Nehammer during his visit to AVL headquarters in Graz.

AVL generated 1.86 billion Euros in turnover last year – Eleven percent flows into research and development – 60 percent of the turnover is already generated by new technologies.

Make sure to explore various interesting topics in the latest issue of our Mobility Trend Magazine!