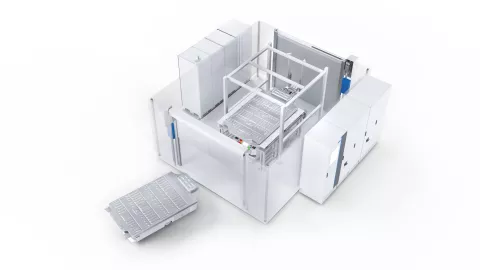

- Modular design for all assembly lines and production volumes.

- Flexible design to support various types of battery modules and packs.

- Ability to test multiple batteries in parallel to optimize footprint and energy consumption. State-of-the-art test libraries.

|

Customizable and Robust Automation System

With AVL PUMA 2™ Production, the user can quickly and easily adapt the user interface and the test procedures to his tasks and needs without any programming knowledge. The automation includes a mechanism to check, compare and log any changes.

Testing Procedures

The AVL testbed supports a wide variety of tests:

- Safety tests: Potential equalization, insulation resistance test, dielectric strength test, HV interlock, etc.

- Functional and performance tests: BMS tests, housing/cooling integrity check, capacity check, DCIR tests, SOC checks, etc.

Multiple Battery Support

EOL test systems support multiple batteries to optimize footprint and energy consumption. Batteries can be tested independently for easy maintenance and flexibility on the production line.

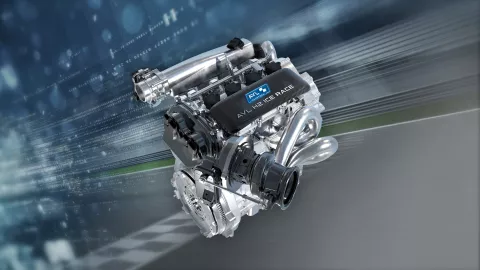

Why develop the most powerful battery if you can’t guarantee its quality and durability? At AVL, our mission is to cover the entire development process, from R&D to EOL, with efficient and reliable tools you can rely on."

– Matthieu Clauet, Department Manager, AVL List GmbH