AVL Japan introduces a Brake Emission Testing System at its Technical Center in Shin-Kawasaki

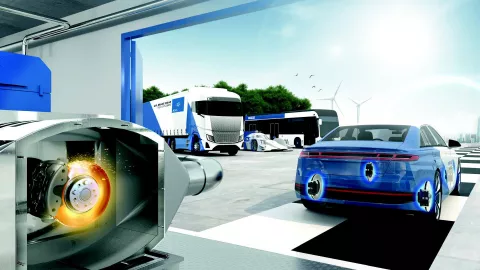

AVL Japan will introduce the latest Brake Emission Testing System to comply with the European Commission's upcoming Euro 7 emission regulations at its Japan Technical Center, which provides engineering services for vehicle development. With this introduction, Japan Technical Center will provide contract testing solutions specialized in brake emission measurement to comply with the regulations of each country.

Kawasaki, Kanagawa, Japan, May 2024:

The Euro 7 emission regulations that will be enforced in Europe from 2025 onward will cover brake emission measurement in addition to existing vehicle emission limits. In order to meet these needs, the Japan Technical Center will install a Brake Emission Testing System that will be compliant with Euro 7. The testing system will be one of the most innovative and comprehensive Euro 7-compliant brake emission measurement test systems installed in Japan.

The features of Japan Technical Center's Brake Emission Testing System are as follows.

- Compliant with Euro 7, which will be enforced in Europe from 2025 onwards, and enables measurement of particulate matter (PM) and number of particles (PN) generated by brake wear.

- Key components include dedicated brake emission measurement equipment, dynamometer, regulated air supply, consumption measurement, and a comprehensive test bench software package.

- Addresses future testing and certification needs.

- Comprehensive solutions based on the emission measurement and testing expertise of Austria-based AVL List GmbH ("AVL") and its Japanese branch, AVL Japan

AVL Japan and Japan Technical Center will continue to provide concepts, solutions, and methodologies in a wide range of fields, not limited to powertrain, in response to various international regulations, including Euro 7.

Message from the Manager of Japan Technical Center:

At the Japan Technical Center, we support our customers with the latest AVL equipment and data processing. In collaboration with AVL's simulation and equipment divisions, we also propose efficient development methods. Japan Technical Center will continue to actively introduce the latest technologies and solutions.

About Japan Technical Center

Japan Technical Center was established in Kawasaki, Kanagawa Prefecture, in November 2016 with the aim of contributing to the development of powertrain technologies for Japanese auto cars, industrial machinery, and ships. Since then, in line with customer requests, the center has provided a wide range of concepts, solutions, and methodologies as well as powertrain technology development. Specifically, we provide various powertrain calibration services for performance, emissions, OBD (On-Board Diagnostic Device), and drivability of various powertrains including hybrid and electric cars, various engineering services such as bench marking and model-based development, mass production design, system.

The main equipment and achievements newly introduced since the Japan Technical Center opened in 2016 are as follows.

- Real Driving Emissions (RDE) Testing:

In the field of RDE (Real Driving Emissions) testing, where emissions are evaluated by actually driving on the road, we installed PEMS (Portable Emission Measurement System), an on-board emission gas measurement device, on a vehicle, applied for modification, selected a route, and conducted measurements according to the RDE. We conducted the measurements in accordance with the RDE.

- Battery Electric Vehicle (BEV) Benchmark:

Benchmarking (efficiency measurements, power limiting, etc.) using a battery electric vehicle (BEV) powertrain test bench.

- Battery emulator battery model:

We introduced a battery model to the battery emulator and used the battery emulator instead of the vehicle's battery. This made it easy to set SOC (State of Charge) and other parameters.

With more than 12,200 employees, AVL is one of the world's leading mobility technology companies for development, simulation and testing in the automotive industry and in other sectors such as rail, shipping and energy. Based on extensive in-house research activities, AVL delivers concepts, technology solutions, methodologies and development tools for a greener, safer and better world of mobility and beyond.

AVL supports international partners and customers in sustainable and digital transformation. The focus here is on the areas of electrification, software, AI and automation. AVL also supports companies in energy-intensive sectors on their way to green and efficient energy generation and supply.

AVL's passion is innovation. Together with an international network of experts spanning 90 locations with more than 50 competence and development centers worldwide, AVL is driving the future of mobility. In 2024, the company generated a turnover of 2.03 billion euros, of which 11% was invested in R&D activities.

For more information: www.avl.com

- EN,

Stay up-to-date as a journalist with our latest press releases concerning company updates, research projects, our latest developments, and more.

Download our fact sheet to get a comprehensive overview about what we do as well as our latest company figures.