In the event of an accident where a battery catches fire or reaches dangerously high temperatures, the AVL Stingray™ One’s punch unit is designed to penetrate the battery and deliver immediate cooling. This innovative approach directly targets the source of the fire, allowing the core to be cooled rapidly with a specialized cooling fluid. Unlike conventional methods, this system minimizes both the volume of cooling liquid required and the overall cooling time.

The Stingray™ One offers a unique, highly effective cooling solution that enhances safety for all parties involved. Its compact design and versatility allow it to be used effectively on a wide range of vehicles, ensuring that first responders can quickly and safely manage fires across various scenarios.

Key Benefits:

- Targeted Cooling: Directly combats the fire at the point of origin

- Low Water Consumption: Efficient use of cooling fluids

- Rapid Cool-Down: Quickly reduces battery temperature

- Compact and User-Friendly: Easy to handle in a variety of vehicle types

|

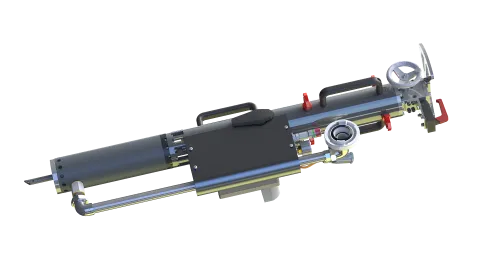

Adjustable Support Unit

Stingray One is characterized by its simple operation and handling. The adjustable support unit enables easy installation across various vehicle types and positions

Remote Control Unit

By using a remote control the AVL Stingray One can be activated from a safe distance of up to 10m, which minimizes the risk of personal injury.

Penetration Unit

The system instantly goes to the source of the fire. This cuts down the amount of cooling liquid required as well as the cooling time.

Integrated Pressure Unit

The Stingray One uses its internal cutting mechanism to rapidly accelerate the piston, ensuring precise and effective penetration.

AVL stands for safe mobility in all areas. AVL Stingray™ One is a prime example of this. With this system, we achieve a completely new level of effectiveness and safety in combating battery fires."

– Urs Gerspach, Executive Vice President, AVL List GmbH

Reach out to us directly or get in touch with our authorized distributors. If you are located in Austria, Germany, Switzerland, South Tyrol, Slovenia, or Croatia please contact Magirus Lohr.

- Get in touch: magirus-lohr@ivecogroup.com

- www.magirus-lohr.at

For the rest of the world, please contact Total Safety Solutions.

- Get in touch: info@totalsafetysolutions.nl

- www.totalsafetysolutions.nl

To obtain certification, a comprehensive guideline was developed in collaboration with an Austrian Institute for Fire Protection Technology and Safety Research, outlining the certification process for this innovative product. The certification involved a series of rigorous tests conducted on high-voltage electric vehicle batteries.

For each test, a worst-case scenario setup was employed to thoroughly evaluate the battery's functioning principles. The battery was intentionally subjected to thermal runaway using a penetration unit, with its state of charge maintained at nearly 100% to ensure maximum energy release and to assess the functionality of the AVL Stingray™ One system.

The cooling process was initiated 30 seconds after the first visible flame, as per safety requirements, making the battery control even more challenging. Remarkably, all flames were extinguished after just 1 minute and 15 seconds, effectively transitioning the battery into a safe state. During the tests, approximately 40 liters per minute of extinguishing agent were used, and the highest measured temperatures reached nearly 1,400°C.

AVL Stingray™ One effectively showcases its capabilities during certification tests through the use of a constant voltage supply. During these tests, several thermocouples, pressure sensors, voltage sensors, and flow sensors were utilized to monitor performance.

AVL Stingray™ One can be effectively used in situations involving damage or overheating of electric vehicle batteries, which poses a risk of thermal runaway and could potentially lead to the entire vehicle catching fire. Battery issues may also occur during the charging process at charging stations or due to technical defects while the vehicle is parked, such as in a parking garage.

In cases where there is a suspicion of thermal runaway - such as after an accident - our system can be proactively installed inside the passenger cabin, regardless of the vehicle's orientation. AVL Stingray™ One provides first responders with valuable additional time to ensure the safety of individuals and protect property when addressing battery fires.

It is essential to note that this system is not limited to battery electric vehicles; it can also be applied to photovoltaic (PV) storage systems. However, the feasibility of installing the system will depend on the specific circumstances and may not be possible in an uncontrolled "full-scale" fire. Each battery fire is unique, and the measures required to manage it may vary accordingly.

In Plug-In Hybrid Electric Vehicles (PHEVs), the exact location of the battery can vary by model. Common locations for battery installation include under the rear seats, beneath the cargo area, or in the trunk. Some PHEVs may also feature multiple smaller battery packs distributed throughout the vehicle.

The placement and setup of AVL Stingray™ One can present more challenges in the trunk area compared to the relatively straightforward installation in the passenger compartment of a Battery Electric Vehicle (BEV). This system has been meticulously designed to address the unique characteristics of BEVs, particularly their exceptionally high energy content, which renders traditional control methods insufficient.

It is important to note that PHEV batteries typically contain significantly less energy than their BEV counterparts, which reduces the threat they pose to first responders in emergency situations. Proper awareness and management of these battery systems can enhance safety and effectiveness during emergencies.

While it is generally not advisable to penetrate a healthy battery pack, there are exceptional circumstances where extraordinary measures may be necessary. The chain reaction known as thermal runaway, which can lead to a battery fire, is not easily controlled by conventional firefighting methods, unlike those for internal combustion engine vehicles. This difficulty arises from the significantly higher energy content of modern high-voltage battery packs.

AVL Stingray™ One offers a targeted solution by directing water to the most critical areas through a single penetration of the battery using a specially designed needle. This needle is specifically engineered to effectively combat fires at the point of origin in Battery Electric Vehicles (BEVs).

This compact and robust extinguishing system has been developed within the automotive industry, benchmarking various battery and vehicle types. Its design makes it suitable for a wide range of applications, earning the trust of industry professionals and first responders alike.

There are various types of lithium-ion batteries in widespread use, each characterized by a unique chemical composition.

While graphite is the common choice for anode material in most lithium-ion batteries, the mineral composition of the cathode varies, defining the different battery chemistries. Cathode materials typically contain lithium along with other minerals such as nickel, manganese, cobalt, or iron. This specific mix plays a crucial role in determining the battery's capacity, power, performance, cost, safety features, and overall lifespan.

It is important to note that the thermal runaway temperature ranges are approximate; exact thresholds or maximum temperatures may vary depending on unique manufacturing processes, additives, and safety enhancements incorporated into the batteries. AVL Stingray™ One has undergone rigorous testing with numerous lithium-ion cathode technologies, particularly those utilizing NMC (nickel manganese cobalt) and LFP (lithium iron phosphate). As a result, AVL Stingray™ One is well-equipped to manage thermal runaway in batteries with various lithium-ion cathode technologies.

The extinguishing water commonly used by fire departments can effectively flood the battery pack within its housing due to the water pressure and the open internal structure of the battery casing. To ensure complete cooling of the entire pack, a flow rate of 50 liters per minute - depending on the type of coupling - combined with a water pressure of 5 to 15 bar must be maintained. This setup allows the water to circulate effectively, reaching all areas of the battery pack to facilitate efficient cooling during emergencies.

After the battery has cooled internally, the extinguishing water exits the housing through venting openings without causing additional and potentially dangerous pressure buildup. These venting openings are typically a standard feature of every Battery Electric Vehicle (BEV) battery pack. They are designed to equalize pressure differences that can occur, for example, when driving in mountainous regions with varying elevations. This ensures that first responders can manage the situation safely, without the risk of pressure-related hazards.

Yes, a coupling is integrated into the AVL Stingray™ One system for water supply, such as the Storz C coupling used in the DACH region. This coupling can be easily adapted to meet local standards, allowing for seamless integration with various firefighting equipment and ensuring effective water supply during emergencies.

In most Battery Electric Vehicles (BEVs), the battery is typically installed beneath the passenger compartment, making it easily accessible for first responders. Ideally, the vehicle's rescue card should be consulted to determine the exact location of the battery. In many countries, first responders can use special software in conjunction with the vehicle’s license plate number to quickly locate the battery.

The penetration point is crucial, as targeting the correct area ensures the most effective response to thermal runaway or battery fires.

he temperatures reached in a battery fire can vary based on factors such as the type of battery, its size, and the specific fire conditions. In general, battery fires can exceed 1,000°C (1,832°F). During AVL Stingray™ One certification testing, lithium-ion batteries were observed reaching temperatures of approximately 1,300 to 1,400°C (2,372 to 2,552°F) during thermal runaway events. These rapid temperature increases pose significant challenges for firefighting and safety. AVL Stingray™ One effectively lowers the temperature well below thermal runaway levels, helping to control battery fires efficiently.