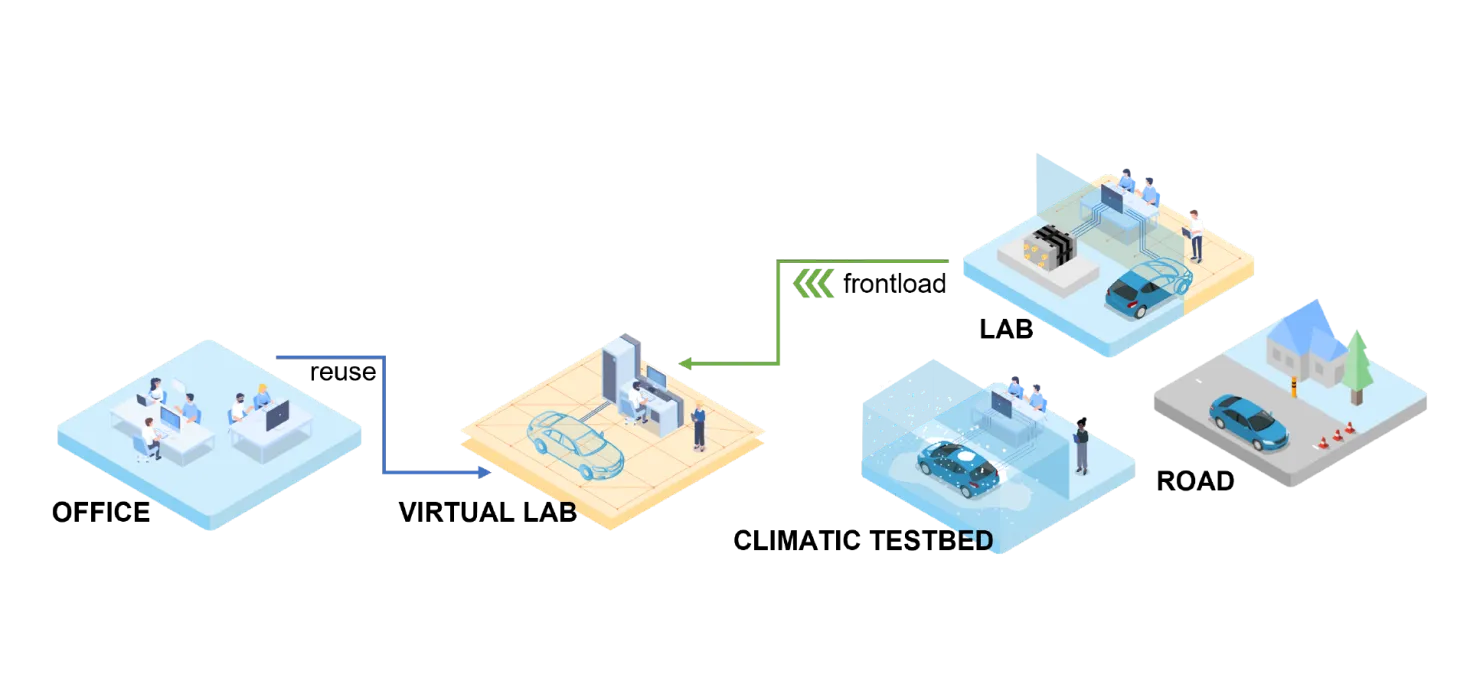

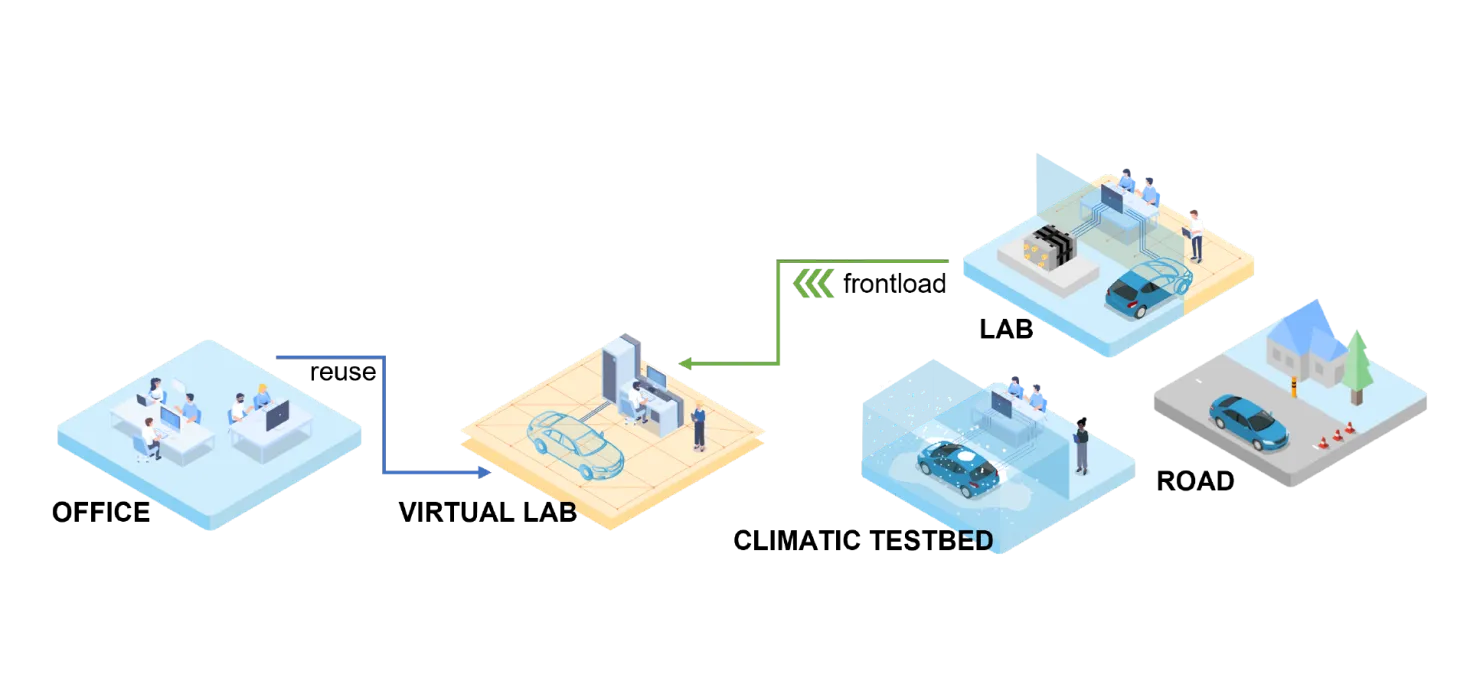

It all starts with high-performance models in the office environment to perform an initial optimization of the operating strategy. To enable a more realistic operation of the fuel cell system, the integration of the vehicle simulation into the test execution is crucial. The easy integration of real-time and non-real-time simulation models allows to further improve the test capabilities. At a later stage, when real controls are already available, the use of a virtual calibration environment ensures a smooth transition to the final validation of the operating strategy on the real hardware.

In fuel cell development processes, it is natural to rely on simulation results to support specification and design of products such as FCEVs. Embedding simulation and virtualization methods at testbeds frees up huge potential to reduce development and validation risks and improve its results quality at the same time.

– Tomas Dehne, Chief Engineer, Fuel Cell Testing Technology, AVL