At AVL we are committed to shape a sustainable future for the next generations. Hydrogen and specifically Proton Exchange Membrane (PEM) technologies are playing an important role in the future energy ecosystem. As market leader for testing instrumentation and tools we are providing solutions for the entire development cycle with technical depth. At the same time our solutions can be applied to a wide range of industrial applications. AVL’s 360° fuel cell testing expertise makes AVL the preferred partner for many leaders in the industry.

At AVL we are committed to fuel cell technologies and strive to bring fuel cell testing to the next level. With expertise and dedication we are developing solutions for our customers for the entire development process. Together with our partner Greenlight Innovation we are shaping the way fuel cells are developed since more than 25 years.

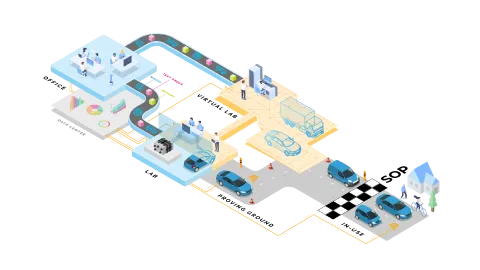

Flexibility, reproducibility and reliability - During development, framework conditions change very dynamically in some cases, affecting both the test specimen itself and its specification. The quality of the data must be high so that the results can be comparable, reproducible and valid throughout the development process. With our test solutions, you can reduce your development effort by :

- Emulate real stress factors and derive accelerated stress tests

- Efficient and effective controls development & calibration

- Frontloading by integrated virtual methodologies to reduce design risks

Efficiency certification - Standards and regulations are evolving rapidly. Specifically in a global market local requirements derived from standards can vary significantly. Our test solutions offer you the necessary flexibility to map a wide range of standards and regulations in practice:

- Certification-guided development throughout the FCEV design validation plan

- Precise determination of electrical and thermal efficiency in driving cycles or in stationary combined heat and power generation.

- Automated execution & reporting in accordance to standards & regulations

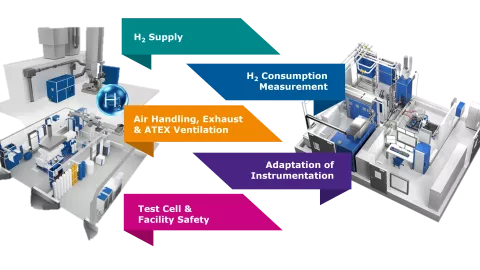

All our test bench solutions include safety systems that are certified by TÜV. This way, we ensure that you meet all requirements for hydrogen safety, fire protection measures and the like when setting up your PEM test fields. We also support you in designing the hydrogen safety concept for new as well as existing test facilities.

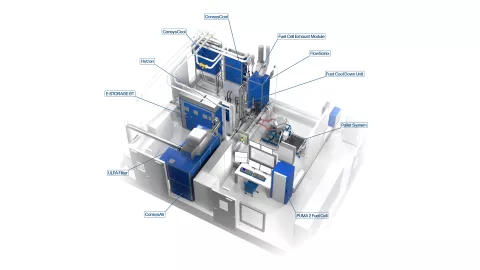

AVL offers standardized and proven test solutions for PEM fuel cells, covering a wide range of applications for different performance classes from the cell to the system. Our solutions range from individual test facilities for hydrogen consumption measurements or fuel cell degradation analyses to complete fuel cell system test benches with environmental simulation. For complete test facilities, we also offer turnkey solutions and consulting. In this way, we make the testing of PEM fuel cells ready for series production and future-proof your investments.

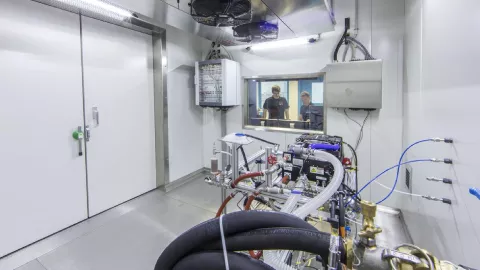

AVL not only manufactures test bed solutions for electrolyzer and fuel cells, but also applies them itself. Thus, competences from development, simulation and test solutions are combined and continuously developed.

Our testing solutions are standardized and proven on the market. Based on sophisticated service concepts, we offer modular implementations and customized test stands.

In addition, our know-how is always part of the scope of delivery. Our employees are perfectly trained and complement your development goals.

A gas conditioning and consumption solution for hydrogen and other gaseous fuels. Learn more about this dedicated product to safely supply and condition gases for the testbed usage.

The Electrochemical Impedance Spectroscopy (EIS) is an innovative stimulus response testing technology for checking the frequency-dependent internal resistance of electrochemical cells such as batteries or fuel cells.

AVL PUMA 2™ Fuel Cell is our intuitive automation system for highly dynamic fuel cell system testing. It is the global industry standard for testbed automation.

Thermal conditions and environment of Units Under Test have strong impacts on real results in driving. For this reason, the thermal simulation must be as exact as possible – which can be achieved via deployment of high performing media conditioning systems.

We make your fuel cell technology more durable – and even more reliable.

Battery packs, modules and cells, fuel cells, e-motor and e-axle solutions must operate safely and reliably in any environment. This can include extreme temperatures and humidity, which cannot be reproduced on the test track or in real test scenarios on the road. This is why we developed the modular AVL Climate Chamber.

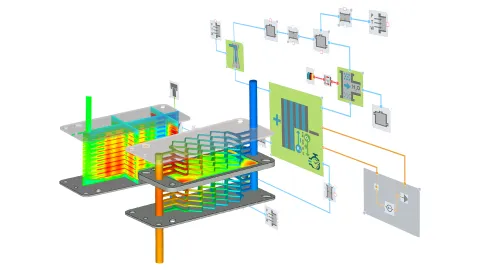

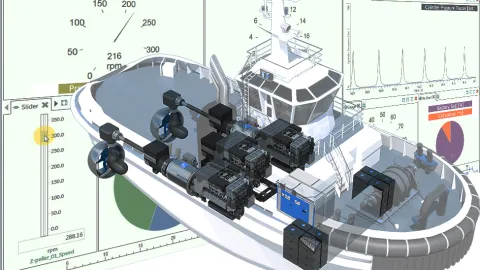

Fuel cells and electrolyzers are excellent solutions for efficiently achieving a CO2-neutral future. Especially since their application is multifaceted. It ranges from vehicles of all sizes to energy generation and storage to the starting point for synthetic fuels (e-fuels). Develop and optimize targeted fuel cell systems by using our simulation.

Enhancing fuel cell system optimization and testing with simulation.

AVL as preferred partner for fuel cell engineering, simulation and testing is providing beyond that integrated solutions for production testing of fuel cell stacks and complete fuel cell systems.

AVL balance-of-plant (BoP) testing solutions are modular and tailored test beds to emulate the real load of a fuel cell system.

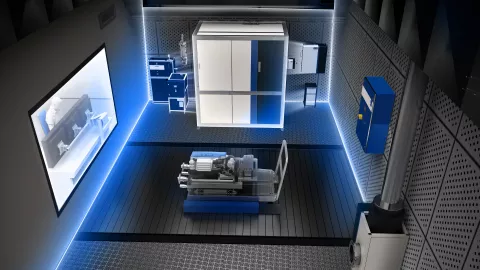

AVL designed the integrated Fuel Cell System Testbed to provide highly efficient and accurate testing while minimizing integration efforts. Reusing our reliable and proven modules and transferring our R&D expertise and maturity into a compact solution was crucial.

Highlights

New Technologies demand not just new testing methods and testing devices but also customized safety measures.

This exclusive webinar gets to grips with all things maritime mobility.

- EN,

AVL and Jaguar Land Rover join forces to deliver zero-tailpipe emissions for premium fuel cell prototype based on the new Land Rover Defender.

- EN,

- EN,

World's first test field for fuel cell propulsion systems in the megawatt range

- EN,

Keytech4EV project successfully completed

New cooperation