With our support, your e-axle system will meet market requirements. Our greatest strength lies in our integration expertise: We consider the overall system and know the targets that the vehicle needs to achieve.

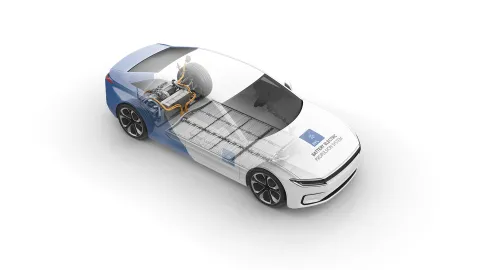

For example, to optimize efficiency, we recommend our two-speed e-axle system for your passenger car, premium SUV, and light-duty commercial vehicles. The optimal efficiency of the system reduces costs and improves performance. Our extensive use of advanced simulation tools supports error-free processing and reduces the use of prototypes.

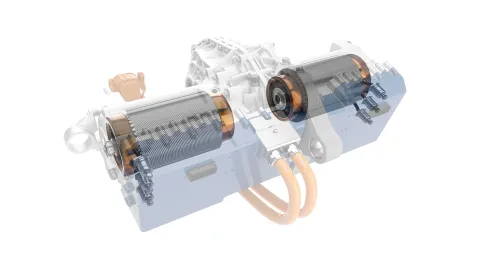

We keep your product costs low with our modular approach: Our e-axles are compact units that integrate the necessary e-drive components – e-motor, transmission, and inverter – and leave maximum space for the battery. These components power the axle of your vehicle directly and reduce complexity – as an out-of-the-box solution for battery electric (BEV) and hybrid electric vehicles (HEV).

This compact design has two additional advantages: optimal integration into the available space, and reduction of weight – a bonus when it comes to improving electric driving range.

Our modular approach also accelerates your time to market: With pre-designed solutions that only need to be customized, we reach the finish line much quicker than if we had to design each individual solution from scratch.

System Integration from a Single Source

With us you get comprehensive expertise in all key areas, under one roof.

Optimization of Your Total Development Costs

We have a team dedicated to "production development, cost optimization, and lifecycle CO2 assessment". This is how we reduce the costs of your individual components and your overall system, and increase sustainability.

Short Time to Market

Our modular approach to e-drive components shortens the development process for you in order to achieve the desired result.

Target Fulfillment

We define application requirements and break these down into subsystem and components. We factor this into the design. After extensive testing, we bring everything together in the overall system for you.