AVL's dedication to innovation is at the core of our comprehensive e-mobility solutions. Our deep expertise in testing and validation is instrumental in ensuring that every electrified propulsion system, whether it be for mobile or stationary applications, meets and exceeds the stringent conformance standards of the industry.

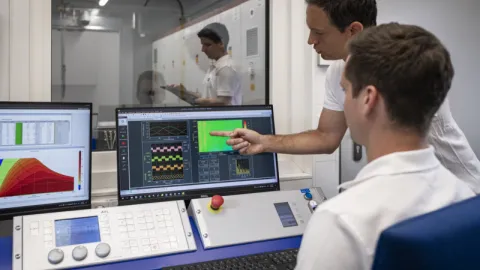

Our global reach and sophisticated array of tools, systems and services are designed to address the electrification challenges faced by our clients. From an integrated software toolchain and virtual ecosystem to a full spectrum of test systems enhanced by advanced measurement instruments, AVL’s approach is tailored for maximum validation efficiency.

We are committed to delivering a highly reliable system environment, equipped with a suite of predefined application packages and scalable lab management systems, all optimized for energy efficiency. This is how we uphold our pioneering role in advancing the future of e-mobility.

At the dawn of the very first electric vehicles available commercially, we were actively directing our development efforts to solve the new technical challenges for the safe and high-quality testing of new electrified propulsion systems and their components. The result of this was today’s complete portfolio of high-speed dynamometers, high-voltage DC sources, dynamic e-motor emulators, safety systems for batteries and fuel cell test chambers, calibration tools for e-drives, facility management tools, and many other advanced testing tools that are now installed at many leading organizations in the automotive industry.

Our scalable approach and solution architecture enable us to satisfy the needs of all our customers, from the traditional passenger car OEMs to new entrants in the aerospace transportation, from Tier 1 to testing centers and research institutes. Modularity and continuous innovation allow us to rapidly address the new requirements of our customers, as repeatedly demonstrated, for example, with our battery, high-speed e-motor, e-axle, and chassis dyno test systems.

Optimize your testing time on a powertrain testbed with our rigging solution.

Our simulation solutions enable an increasing degree of highly efficient and time-saving virtual validation, as realized with our inverter test systems and our virtual test systems. The assisted calibration tools accelerate the time-consuming tasks of finding the optimum parameters in the drive and fuel cell controllers. The test lab management systems facilitate the management of a large volume of test equipment and units under test, a high degree of equipment utilization, and the lowest energy consumption, as in the case of battery testing fields.

Test and Validation Topics

|

and many more. |

Electrified transportation is the key to reduce CO2, and plays an important role in tackling climate change. From hybrid to battery electric and fuel cell electric models, we have the expertise to support you in making the right architecture choice for your electrification portfolio. Our solutions cover testing methodologies and validation solutions, with comprehensive application knowledge.”

– Luigi Giordano, Director Electrification Application, AVL List GmbH

AVL has launched a comprehensive series of test solutions for electrified propulsion systems, designed to validate the performance of batteries, e-motors, e-axles, inverters, and entire EVs on a chassis dyno. Covering the full development lifecycle from software validation to production and field testing, these solutions ensure that each component and system meets the evolving technical demands of the electric vehicle industry, thereby supporting the transition to sustainable transportation.

Battery Testing

The aim of our portfolio of battery test systems is safe and precise testing of batteries in all steps of their validation program, covering every need from battery cell research testing to battery pack characterization, including durability, environmental testing, and abuse testing.

E-Motor Testing

Our e-motor testing portfolio includes solutions for performance, back-to-back, as well as NVH (noise, vibration, and harshness) and EMC (electromagnetic compatibility) testing. Our test systems enable us to determine and analyze the electrical, mechanical, thermal, and acoustic characteristics of the e-motor.

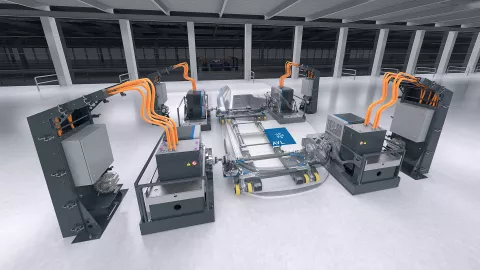

E-Axle Testing

Our solutions for testing e-axles and complete propulsion systems cover a wide range of functionality and use cases, including, for example, accurate measurement of performances and NVH, automatic calibration of control units, efficient durability validation, replication of driving maneuvers, and full investigation of energy flows.

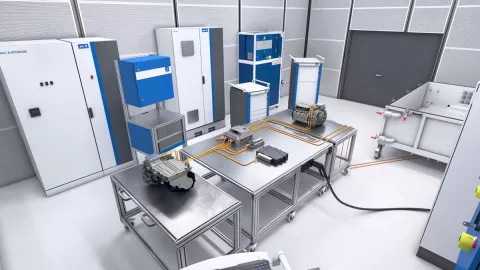

Inverter Testing

The AVL Inverter Test System provides an environment in which all inverter functionalities and failure modes can be optimized. This allows easy design and validation of the inverter in the early stage of development, as well as optimization of its integration with all other components in the electric propulsion system, providing you with the most efficient process possible.

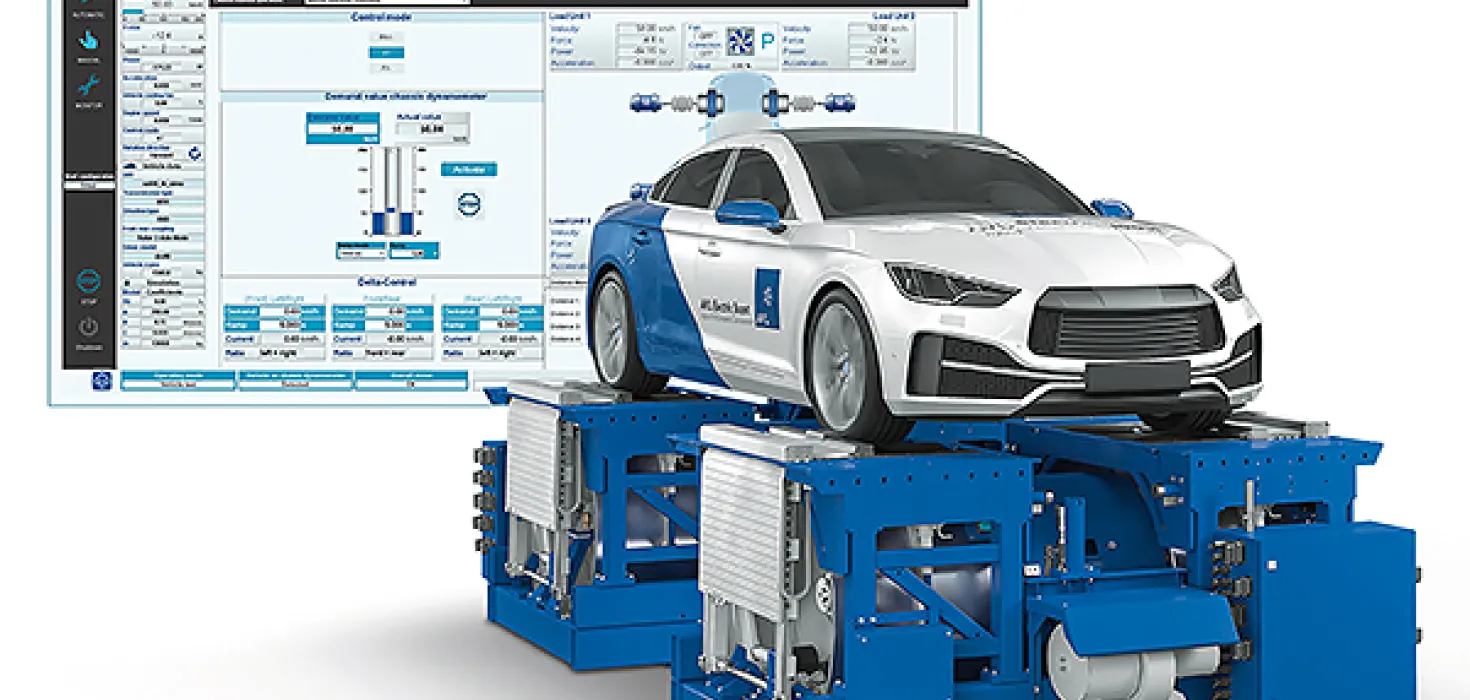

Vehicle Testing

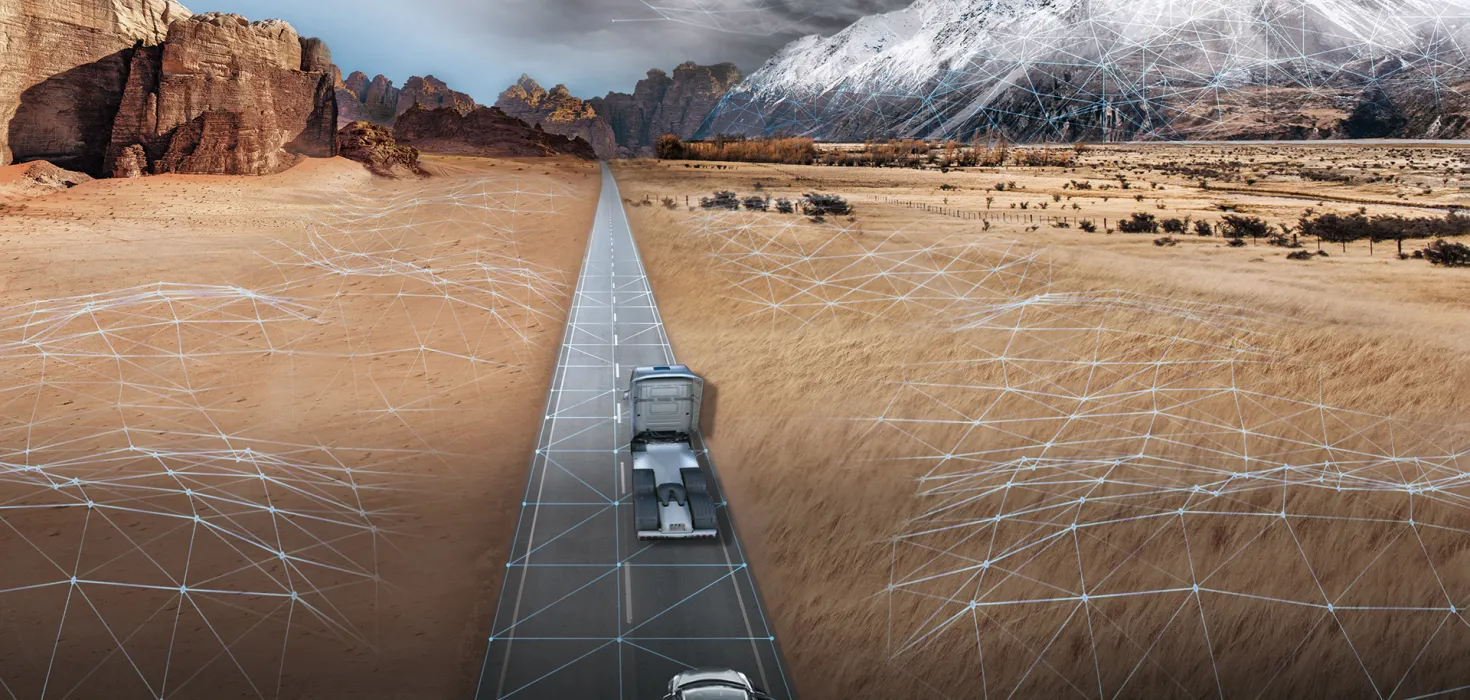

The AVL chassis dyno testbed simulates the road realistically, in environmental conditions that can be reproduced. Vehicle characteristics such as vehicle mass, speed, power, tractive force, or axle load are mapped in AVL vehicle testbed products. AVL offers more than 18 standard vehicle testbed configurations with diverse options and variations, covering a wide range of customer-specific solutions for all market segments.

AVL is the only company in the world to combine expertise in propulsion system design with competence in state-of-the-art measurement and testing technology. Our test systems deliver high precision, consistent, comparable results that help lower development times and costs significantly. We ensure our customers receive tailored, timely support, with the most competent global service organization.

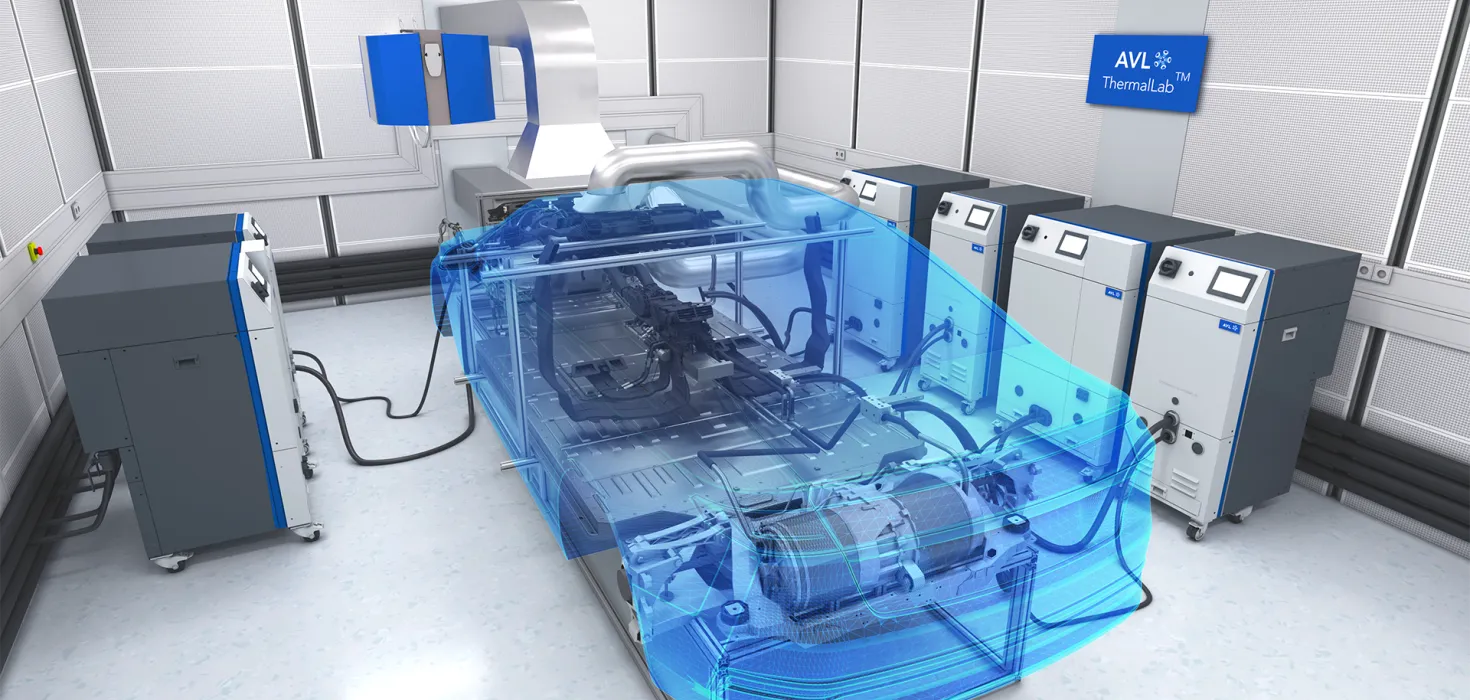

Thermal Testing

AVL’s Thermal Lab™ allows you to frontload thermal management testing from the road to the rig using a model-based Hardware-in-the-Loop (HiL) approach. This includes battery lifetime and system costs versus driving range in an early development phase. The significant reduction of vehicle tests in wind tunnels and test tracks speeds up development, reduces costs, and could potentially save a prototype generation.

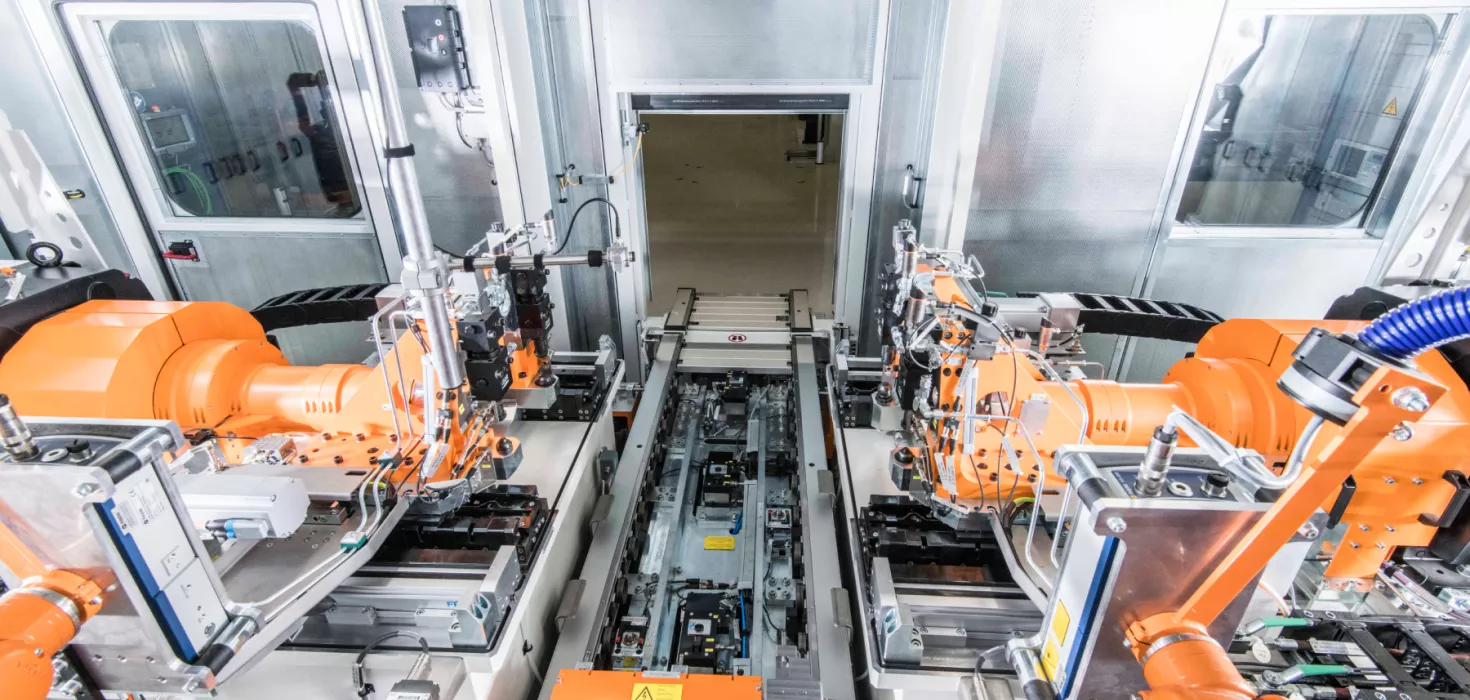

Production Testing

The shift towards electrified propulsion systems has increased the demand for new End of Line (EoL) and Conformity of Production (CoP) testbeds. To meet the requirements of production testing in such modern test fields, we offer a new series of test systems for battery, e-motor, and e-axle. Designed to allow unmanned operation around the clock, these solutions ensure the highest levels of productivity, maximizing return on investment.

Energy and Infrastructure Testing

The charging experience is one of the greatest differences between vehicles with a battery and vehicles with a fuel tank. The core charging requirements are established and standardized, however, both the technology and applications are still in the early stages of maturity. Therefore, they are under intense market pressure to expand, evolve, and improve. To address these increasing demands with a high degree of testing effectiveness, AVL is introducing a product line of test equipment for charging. It delivers features that build on proven automation and data management tools to reduce engineer attention, while also remaining highly flexible to adapt to whichever direction the market may take in the future.

Virtual Testing

We offer a set of advanced software tools for all test solutions, to achieve real-time emulation of driving conditions, vehicle, and propulsion system components, or to enable automatic calibration of propulsion system control units. These tools enable earlier virtual validation and an efficient exchange of models and parameters between the test systems.

Fuel Cell Testing

Hydrogen and, specifically, fuel cell technologies play an important role in a sustainable future energy ecosystem. As market leader for testing instrumentation and tools, we provide solutions for the entire development cycle across a wide range of industrial applications.

AVL is the global partner for the most efficient, flexible, and reliable testing solutions, for all electrified transportation vehicles, for components, and for complete systems, and using the most innovative technologies.

20

years of experience in electrification and fuel cell engineering

> 5000

experts in the field of e-mobility

> 1000

test systems for electrification components and systems

Battery electric vehicle (BEV) development requires significant adjustments to the development process and its environment.

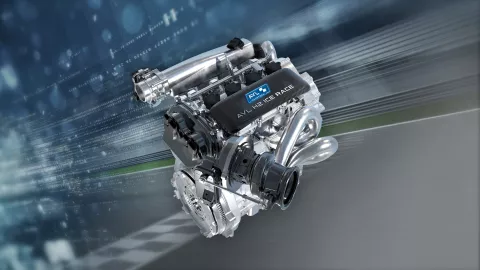

AVL RACETECH, the motorsport department of AVL, presents the prototype of an innovative H2 internal combustion engine. The power unit is a compact, hydrogen-powered 2-liter turbo engine, with intelligent water injection, which achieves a totally new performance level. The first racing engine that AVL RACETECH is developing and building in-house.