With us as your partner, you can overcome all the challenges of PEM system development. As experts in PEM system power density, we maximize the power density of your PEM systems for you with low weight, which also has a positive effect on the form factor. In addition, we optimize efficiency at system level – and thus the efficiency specific to the application.

As far as costs are concerned, we make sure that we fine-tune every technically feasible solution into a business case that creates value for you. To do this, we consider the global supply chain and provide production engineering. Hence, we guide your development projects towards industrialization and thereby emphasize aspects such as ease of assembly, process optimization, and factory design.

In all of this, our experience from fuel cell industrialization projects is of great benefit to you. We are also happy to support your development processes at your site. And we have a comprehensive test infrastructure available for the production-ready development of your PEM systems. We are fully integrated both vertically and horizontally, offering all the services you need.

Expertise in Methods and Fuel Cells

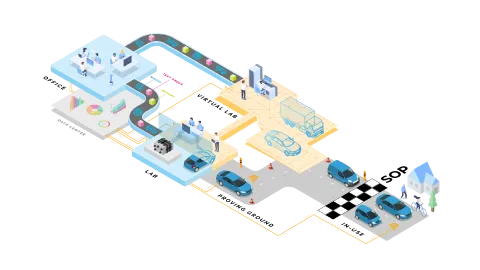

We provide comprehensive development with precise simulations that move important process steps forward in time. In the same way as for the classic or hybrid engine area.

We know how to manage a Design Verification Plan (DVP) and combine this knowledge with the fuel cell expertise that is anchored in our company. We are applying our many years of experience in disciplines such as electrics and electronics (E/E), systems engineering, and design to your PEM fuel cell.

In detail: When developing a PEM system, our specialist department only accounts for around 12 to 14 percent of expenditure. The rest comes from classic disciplines, in which we apply existing knowledge from engine packaging, validation, etc. to the fuel cell.

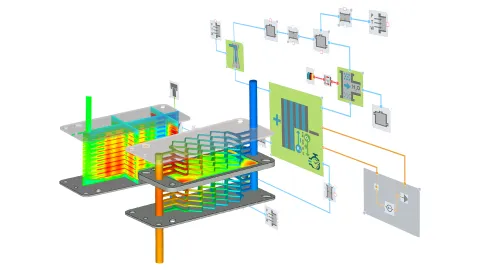

Fuel Cell System Design

The system design is crucial to success when it comes to high power densities. To achieve the most compact implementation possible, we focus on the interfaces between the stack and the components.

Control Software

For system control, we develop production-ready, modular software for operation with implemented diagnostics, processes, and safety functions.

Validation and Testing

We validate and verify your PEM system up to the release recommendation for series production. For this, we have the proven methodology (DVP) as well as the state-of-the-art testing infrastructure at our test centers. Just like you are used to from the traditional field of the internal combustion engine (ICE).