TCD and AVL Collaborate in the Area of Model-Based Development To Achieve Best-In-Class Vehicle Performance and Driver Satisfaction

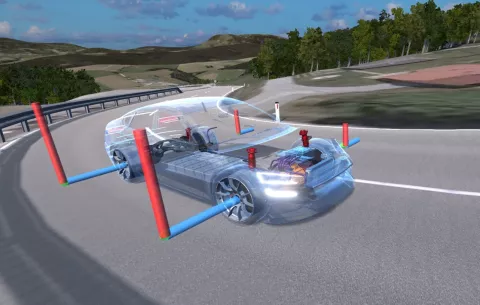

Introducing cutting-edge technologies such as virtual vehicle concept definition, Driver-in-the-Loop and model-based calibration and testing.

Graz, Austria, February 2022: AVL is proud to be chosen by Toyota Customizing & Development Co.,Ltd. (TCD) as partner in the area of model-based vehicle development. The partnership enables the introduction of cutting-edge technologies such as virtual vehicle concept definition, Driver-in-the-Loop (DiL) and model-based calibration and testing to promote efficiency and quality improvements during the development process.

Starting in 2016, the successful collaboration constantly evolved towards a trusted long-term partnership. The range of collaboration areas constantly increases, always having the goal of maximizing the virtualization of the development process and achieving best-in-class driving performance in mind. "Using AVL's vehicle simulation tool AVL VSM™ as well as state-of-the-art analysis, visualization tools and the jointly developed methodology enabled us to achieve best-in-class driving attributes and digitalization of the development process", Hiroshi Yuchi, General Manager Research & Development at TCD.

Mario Oswald, Head of Virtual Vehicle and Energy Management at AVL, adds: "Having the chance of supporting TCD vehicle development is a great honor for AVL. Jointly pushing the limits and combining competences drive the successful collaboration".

About TCD

TCD’s mission is to develop and sell a wide range of aerodynamic, suspension, exterior, and interior parts, as well as superbly functional complete vehicles that fit perfectly with the car-based lifestyles of its customers and heighten the excitement of everyday life.

Close collaboration with Toyota Motor Corporation allows TCD to develop products with a close eye on market trends. The company’s unique organization that integrates sales, planning, design, development, purchasing, production, installation, quality, and after-sales service enables TCD to sell exciting products that meet the needs of its customers through Toyota’s nationwide network of dealers. For more information: www.toyota-cd.co.jp/english

AVL is a world-leading technology company specialising in development, simulation and testing in the automotive industry and other sectors such as rail, marine and energy. Through extensive research, AVL delivers concepts, technology solutions, methodologies and development tools for sustainable, safe and advanced mobility and beyond.

AVL supports international partners and customers in sustainable and digital transformation, with a focus on electrification, software, AI and automation. AVL also supports companies in energy-intensive sectors on their way to green and efficient energy generation and supply.

For more information: www.avl.com

- EN,

- EN,

- EN,

Stay up-to-date as a journalist with our latest press releases concerning company updates, research projects, our latest developments, and more.

Download our fact sheet to get a comprehensive overview about what we do as well as our latest company figures.

Get in touch with our Press-Team

For all press and media enquires please email: