AVL Graz to Receive Four Cutting- Edge Battery Test Systems

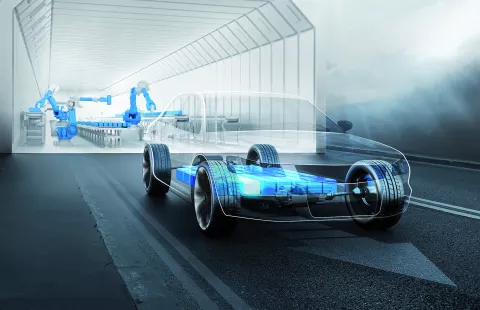

Covering an area of 400 sq. m, four new battery testing facilities, which will rank among the most advanced in Europe, are being erected by AVL List GmbH. By expanding its electric mobility testing center, AVL has become a driving force behind large-scale battery development, aiming at improved fulfilment of current and future customer requirements.

The automotive development process – from preliminary testing and design through to development and validation – plays a central role in fulfilling the high quality and safety standards for future batteries. In response to the ever increasing industrial requirements, four new battery testbeds are to be added to the AVL Test Center. They are expected to go into operation in spring 2018.

The most striking feature of the new testbeds results from the combination of the highest-possible test parameters voltage, power and temperature-changing speed in larger test chambers than previously – at present there is no other testbed that satisfies all of these specifications at such a high level. In future, the four state-ofthe- art testbeds will be covering the development of batteries up to 1200V – right now 450V batteries are standard (900V for premium-class vehicles). Measuring 4.5 by 3.3 meters, the thermal chamber even has the ability to test truck batteries. By expanding its e-mobility testing center, the experienced AVL battery team can support customers in the field of large-scale battery development in the most effective way possible.

AVL started developing lithium batteries for the global passenger car and commercial vehicle industry ten years ago. New technologies are being developed to support the optimal integration of all types of cells in batteries, and to make them suitable for large-scale production. To address battery validation, AVL already erected four battery testbeds with trendsetting 800-1000V-capabilities back in 2010. In 2012, AVL developed and implemented the “AVL CoupE” – the first 800-volt electric car (BEV). This was the concept vehicle for battery technologies for large-scale BEVs, which are to hit the market in the next few years.

AVL is a world-leading technology company specialising in development, simulation and testing in the automotive industry and other sectors such as rail, marine and energy. Through extensive research, AVL delivers concepts, technology solutions, methodologies and development tools for sustainable, safe and advanced mobility and beyond.

AVL supports international partners and customers in sustainable and digital transformation, with a focus on electrification, software, AI and automation. AVL also supports companies in energy-intensive sectors on their way to green and efficient energy generation and supply.

For more information: www.avl.com

![PR_AVL_CONCERTO_5_SANTORIN_MX2_Bild[2] PR_AVL_CONCERTO_5_SANTORIN_MX2_Bild[2]](/sites/default/files/styles/landscape_small/public/pressrelease/Company/PressReleases/Press%20Releases%202017/PR_AVL_CONCERTO_5_SANTORIN_MX2_Bild%5B2%5D_0.jpg.webp?itok=yFVZY0gr)

- EN,

- EN,

- EN,

- EN,

Stay up-to-date as a journalist with our latest press releases concerning company updates, research projects, our latest developments, and more.

Download our fact sheet to get a comprehensive overview about what we do as well as our latest company figures.

Get in touch with our Press-Team

For all press and media enquires please email: