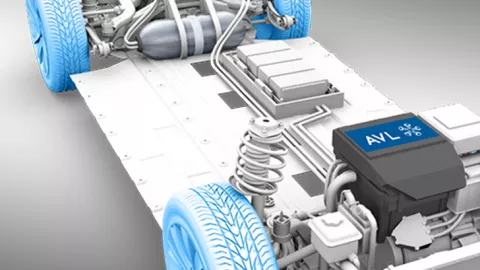

Frontloading is an effective measure to shorten product development cycles. It is particularly important in the powertrain development of fuel cell electric vehicles (FCEV) featuring multiple physical domains, such as mechanical, electrical, fuel cell system, battery system, thermoregulation and controls. Mastering their complexity calls for advanced system simulation tools to efficiently explore the vast design space of material, geometry and operation parameters.Low temperature proton exchange membrane fuel cells (LT-PEMFC) in hydrogen-powered vehicles are a viable emission free solution featuring short refuelling times and long driving ranges. To achieve higher market shares of FCEVs, a significant cost reduction needs to be achieved while ensuring enough service life and sufficiently high energy conversion efficiencies. Electrochemical devices, fuel cell and battery are prone to degradation during their life-time. Aging phenomena need to be considered already during initial system layout studies when targeting to approach engineering limits. The performance and degradation of electrochemical systems is influenced by multiple interactions on inter- and intra-component level. Here, mechanistic models on all relevant levels are crucial to assess the global system performance and local degradation in a closed causal chain. In this 60-minute-webinar, Johann Wurzenberger, Team Leader at AVL Advanced Simulation Technologies, will present a paradigm shift in system level modelling of FCEVs. This is achieved with a multi-domain modelling framework combining models of different physical domains featuring different scales, frequencies and numerical requirements. The core of the approach are spatially and temporarily resolved models for fuel cell and battery. The models are integrated into the FCEV model running in transient operating conditions.