Testing and validation is an expensive and complex activity. This calls for large numbers of prototypes, along with costly test trips to examine the capability of systems in different climatic regions. Even mitigating these costs by switching much of the test burden from on-road and on-vehicle to climatic testbeds can be costly. Testbeds, that accommodate tests within the relevant range of non-standard ambient conditions, often come with huge hourly costs. A solution is therefore vital, to manage the performance and the cost efficiency.

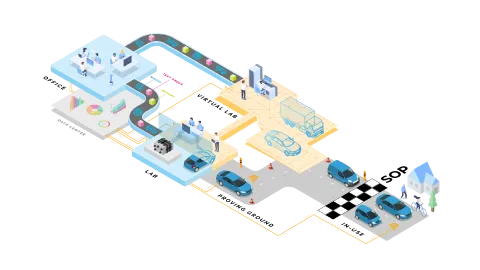

Frontload Tests

Replacing missing real components with simulation models in early development phases.

The Power Of Models

Es soll eine Verbindung zwischen den Simulationen und ihrer Nutzung am Prüfstand sichergestellt werden.

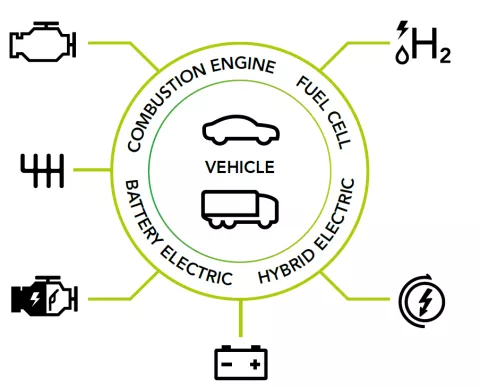

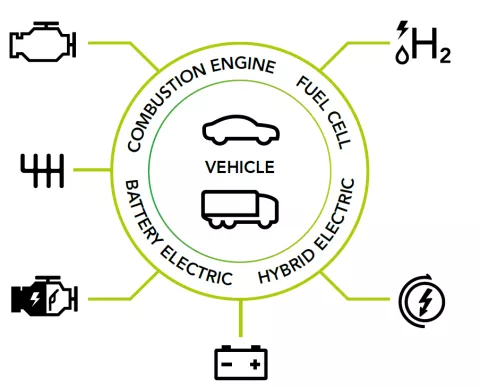

Meeting New Trends

Stringent emission and CO2 regulations drive the development of new propulsion concepts.

Variety Of Variants

The variety of different powertrain and vehicle variants is increasing.

Based on more than 10 years of experience using Virtual Testbeds in calibration projects at both AVL and our customers, the solution is ready to support your:

- Engine development (e.g. calibration at non-standard conditions, robustness investigations)

- Powertrain development (e.g. shift strategy optimization)

- Hybrid systems development (e.g. optimization of operating strategies, integration testing)

- Fuel cell development (e.g. calibration at non-standard conditions)

Already applied in hundreds of development projects, our virtual testbed covers:

- Passenger cars

- Light-duty and medium-duty vehicles

- Heavy-duty vehicles

- Off-road machinery

Validated use cases are available for all of these configurations.

30% Less Prototypes

Reduce your fleet of test vehicles by up to 30%.

25% Less Costs

Lower your development costs by up to 25% and significantly decrease your development time.

Maximized Quality

Improve the quality and robustness of your datasets.

Modelling

Integrate models to represent any powertrain and vehicle configuration. If needed, AVL CRUISE™ M helps you to create models with the right accuracy.

Hybrid-Electric Applications

Validate the interaction of subsystems and different control units as early and as effectively as possible. The Virtual Testbed helps you to consider highly dynamic signals in the testing communication on system level.

Fuel Cell Development

The Virtual Testbed naturally extends the portfolio of virtualization for the development of fuel cells. It supports you with system integration testing, 0ptimization of operating strategies, diagnostic function validation and degradation testing.

With our Virtual Testbed we are providing a holistic testing environment and consistent toolchain. It comprises modelling capabilities, methodologies and engineering know-how in a single solution.

– Morgan LeCossec, Business Development Manager, Smart Calibration and Virtual Testing, AVL

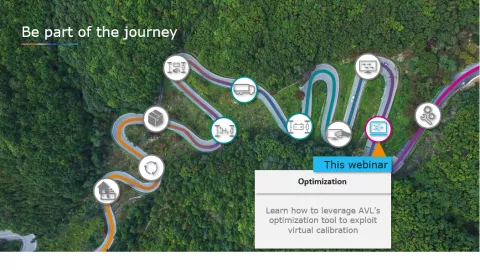

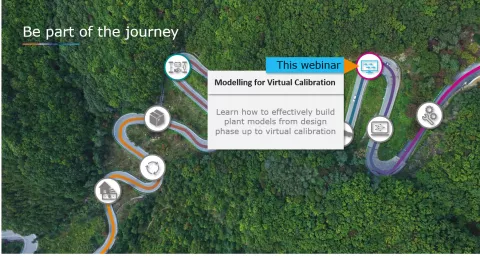

We are constantly working on new solutions. The following might be interesting for you:

Moving steadily into the future: Find out what’s brand new in the field of virtual calibration.