The emissions of particulates from internal combustion engines are globally restricted by local regulatory bodies, each with slightly different measurement methodologies and acceptance criteria. The various regulations share a common requirement that the mass of particulates must be measured and reported as an input for engine certification.

What is particulate matter?

Particulate matter (PM) is formed when exhaust gas from internal combustion engines mixes with ambient air. Under these conditions, the combustion products present in the exhaust (soot, hydrocarbons, sulfates, nitrates, and ash) form particulates of various sizes via processes of adsorption, condensation, and agglomeration.

Heavy Duty EnginesThe initial reason of existence for the Smart SamplerPLUS with over 40 years of improvements incorporated into a single product. |

Light Duty Vehicle TestingUS CFR 40, 1066 added another field of application. The Smart SamplerPLUS software and hardware were adapted to be compliant. |

Off Road TestingAn application nearly as old as the Smart SamplerPLUS. Flexible design supports large engines testing in every situation. |

|

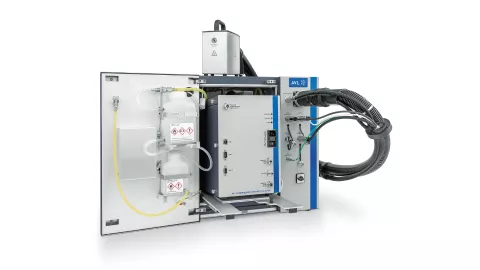

A partial flow dilution system such as the AVL Smart SamplerPLUS mixes and dilutes a small sample of the exhaust flow with air under controlled conditions. This allows particulates to form in a repeatable manner simulating reactions in the atmosphere. The system samples the diluted exhaust over a filter medium where the particulates are captured and subsequently weighed. A partial flow system operates on a principle similar to a full flow constant volume system, but the partial flow system dilutes only a fraction of the total exhaust flow, while a CVS (constant volume sampler) dilutes the entire exhaust flow.

Its flexible design also allows the AVL Smart SamplerPLUS to be used as a diluter for particle counting according to ECE regulation No. 49 and Global Technical Regulation No. 4. For particle counting, the system operates as it does for gravimetric measurement with a proportional sample of the diluted exhaust diverted to an optional particle counting device.

• Easy installation in combination with the AVL Particle Counter

• Software automation takes care of all the controls and calculations

• Easy integration into automation system with a wide set of AK commands

System Operating Parameters

|

Transformation time (t50) |

<150 ms with 2 m interconnect |

| Exhaust temperature range |

25 – 500 °C |

| Exhaust pressure range |

Ambient pressure ± 12 millibar (no pressure pulsation) |

| Altitude simulation |

3,500 m full loading capacity and 5,500 m limited loading capacity |

| Flow accuracy |

Gp ≤ 5 % at dilution ratios <20 |

| Flow range over filter | 0.5 g/s - 2.0 g/s |

| Flow controllability |

From dilution ration 1:1 - 120:1 |

| Filter holder |

For up to 4 single filters |

Benefits of gravimetric particulate matter sampling.

Compliant with Emission Regulations

Compliant with EURO VI for particle mass and number counting (add-on sampling) and compliant with EPA CFR 1066 chassis dyno testing and CFR 1065 heavy duty testing.

Flexible Filters

One to four separated filters and an automatic filter changer that enables the sampling of up to 21 filter pucks for automated test runs while providing increased safety.

Efficient Operation

The Smart Sampler’s highly efficient control of flow accuracy and stability coupled with low power and shop air consumption can save up to 70 % of ownership costs.

High Testbed Uptime

LFE and SAO design allow long term measurement stability. Recalibration can be done by simply swapping the master LFE. Alternatively, an external flow measurement device can be connected to the SPC to validate the LFEs.

Flexible Design

The flexible design of the AVL Smart Sampler also enables it to be used as a diluter for particle counting according to EU VI and STAGE V.

Altitude Simulation

The Smart SamplerPLUS contains an extra pump cartridge that allows attitude simulations of up to 3,500 m with full sampling capacity.

Rapid Test Cell Changeovers

The Smart Sampler has several flexible mounting options: trolley mount, remote mount of main cabinet up to 12 m away from filter cabinet and wall mount. These mounting possibilities allow users to fully optimize cramped test cells and enable rapid test cell changeovers.

Automatic Filter Changer

The automatic filter changer allows sampling of up to 21 filter pucks for automated test runs and provides increased safety. 3 test runs can be run consecutively with an additional single filter holder.

Lower Maintenance Costs

The updated Smart SamplerPLUS Control Cabinet features a list of hardware enhancements that massively improve the serviceability, accessibility to parts as well as quality of life. Brand new PC and manifolds with better access, push in RTDs as well as new pump module are just a few features that come with the system.

Intuitive Software

The Smart SamplerPLUS software has been completely reworked: It now contains many new features such as flow calibration for enhanced repeatability, an energy usage graph, and completely updated reports for improved readability. The new software features intelligent troubleshooting capabilities that allow for high system uptime.