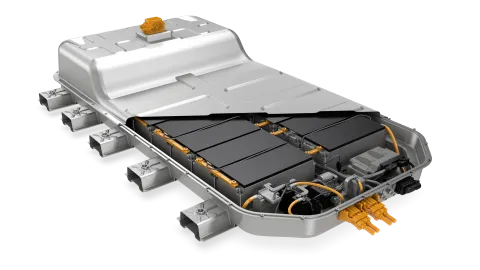

AVL E-STORAGE supports a range of different testbed configurations and inspires the user to create and run various kinds of use cases. In addition, this provides you with the potential to minimize the use of resources. From battery tests to battery emulation, and from single components to complete electrified powertrains, the E-STORAGE family offers you comprehensive, versatile, and highly flexible testing solutions.

With more than 10 years of experience in electrification we constantly adapt AVL E-STORAGE to the market’s future needs. Our portfolio bridges the gap from low voltage to high voltage, and from a few kilowatts up to megawatt clusters. With that, you profit from intelligent solutions and robust interfaces with high levels of usability, enabling you to purely focus on your test application.

AVL E-STORAGE™ Portfolio

The AVL E-STORAGE solution portfolio provides a wide range of different devices that can be combined to provide maximum flexibility. All devices are on the cutting edge of technology in terms of dynamic performance thus enabling test results that reflect real world conditions. All our E-STORAGE devices are available as battery emulators. No matter if the unit-under-test (UUT) is an inverter, e-motor, e-axle, or any other electrical component. AVL E-STORAGE focuses on low output ripple and offers modes for high voltage dynamics or voltage stability. This ensures a stable DC power supply to master the challenges of UUT testing.

Testing Battery Cells

To improve and accelerate electric vehicle development, AVL has developed a series of battery cell cyclers. These are bi-directional, multi-channel DC power supplies that test, diagnose, characerize and validate battery cells. They can achieve an output current that ranges from ± 2 A to ± 2,400 A thanks to their multiple variants and the parallelization of their channels. The AVL CELL TESTER™ 600A uses a unique current measurement technique providing the best accuracy (0.01 % of actual value) among high current cell testers while using only one current measurement range.

The AVL Universal Charger™ is a breakthrough solution to revolutionize the electric vehicle (EV) industry. With a focus on comprehensive testing, and seamless emulation of the charging process, this innovative technology eliminates the complicated challenges and covers all global standards. Regardless of the type of battery-powered vehicle (PHEVs, BEVs, FCEVs), the Universal Charger provides an unparalleled platform for thorough evaluation. Its capabilities go beyond charging to include advanced features such as charge and discharge simulations, hardware-in-the-loop (HIL) testing, and seamless integration of vehicle-to-anything (V2X) communication systems.

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL Battery Testing Solutions – Brochure

Learn more about our holistic battery testing portfolio and solutions.

AVL Battery Testing Solutions – Whitepaper

Learn more about our testing approach and solutions offerings.

Solution Sheet AVL E-STORAGE SiC™

AVL E-STORAGE BTE™ 800V – Solution Sheet

DownloadAVL E-STORAGE BTE™ 1200V – Solution Sheet

DownloadAVL E-STORAGE LV™ – Solution Sheet

For testing low-voltage micro and mild hybrid systems (48 V).

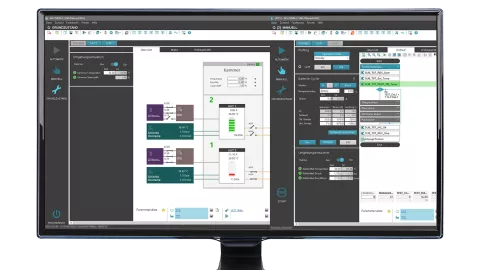

AVL´s intuitive automation system for battery testing, from cell to module and pack.

Battery tester and emulator for research and development, testing and validation.

Battery tester and emulator for research and development, testing, and validation purposes.

Highly dynamic, regenerative power supply optimized for the testing of low-voltage micro and mild hybrid systems.

Bi-directional multi-channel DC power supply to test and validate battery cells.

Battery packs, modules and cells, fuel cells, e-motor and e-axle solutions must operate safely and reliably in any environment. This can include extreme temperatures and humidity, which cannot be reproduced on the test track or in real test scenarios on the road. This is why we developed the modular AVL Climate Chamber.

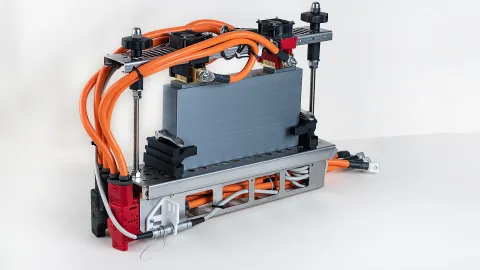

The AVL CELL FIXTURE™ is an ergonomic and easy-to-use platform that holds the battery cell in its testing environment and connects it to testing equipment. The cell can be easily installed on the fixture in a separate location. The fixture is then quickly mounted in the testing environment. This significantly reduces downtime. In addition, AVL has developed the cell tab contacting element with a 600A capability and low resistivity.

AVL is the world’s largest independent company for development, simulation and testing in the automotive industry. Drawing on its pioneering spirit, the E-STORAGE segment provides the capacity to shape future mobility trends, worldwide.

> 10

years of experience in electrification.

> 2500

installed E-STORAGE devices worldwide.

4

E-STORAGE production sites.

26

countries represented.

45

affiliates

Highlights

Everything that excels at a glance: AVL highlights you shouldn't miss.

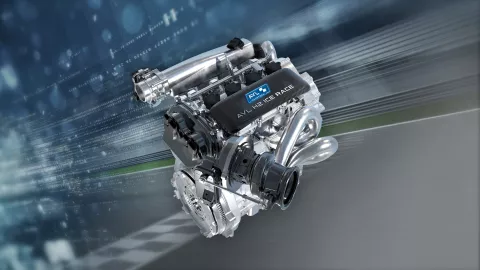

AVL RACETECH, the motorsport department of AVL, presents the prototype of an innovative H2 internal combustion engine. The power unit is a compact, hydrogen-powered 2-liter turbo engine, with intelligent water injection, which achieves a totally new performance level. The first racing engine that AVL RACETECH is developing and building in-house.

OEMs, battery and cell suppliers have to continuously develop new packs and cells for the evolving automotive market. Test systems for validating battery cells and packs need to be state-of-the-art. This webinar discusses existing battery challenges and explains how intelligent automation can make testing more efficient.

AVL List GmbH has appointed Gustav Tuschen as new board member and Executive Vice President. The top manager with international experience was previously at Daimler Buses, where he was head of development. As of December 1, 2022, the 60-year-old is responsible for the corporate development and global alignment of AVL in the commercial vehicles sector.